HoneywellHC900 Process & Safety Controller User and Installation Manual

Notices and Trademarks

Copyright 2017 by Honeywell

Revision 6, 21 April 2017

Warranty/Remedy

Honeywell warrants goods of its manufacture as being free of defective materials and faulty workmanship. Contact

your local sales office for warranty information. If warranted goods are returned to Honeywell during the period of

coverage, Honeywell will repair or replace without charge those items it finds defective. The foregoing is Buyer's sole

remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and

fitness for a particular purpose. Specifications may change without notice. The information we supply is believed

to be accurate and reliable as of this printing. However, we assume no responsibility for its use.

While we provide application assistance personally, through our literature and the Honeywell web site, it is up to the

customer to determine the suitability of the product in the application.

Honeywell Process Solutions

1250 W Sam Houston Pkwy S

Houston, TX 77042

This DANGER symbol indicates an imminently hazardous situation, which,

if not avoided, will result in death or serious injury.

This WARNING symbol indicates a potentially hazardous situation, which, if

not avoided, could result in death or serious injury.

This CAUTION symbol may be present on Control Product instrumentation

and literature. If present on a product, the user must consult the

appropriate part of the accompanying product literature for more

information.

This CAUTION symbol indicates a potentially hazardous situation, which, if

not avoided, may result in property damage.

WARNING

PERSONAL INJURY: Risk of electrical shock. This symbol warns the user of a

potential shock hazard where HAZARDOUS LIVE voltages greater than 30 Vrms,

42.4 Vpeak, or 60 Vdc may be accessible. Failure to comply with these

instructions could result in death or serious injury.

ATTENTION, Electrostatic Discharge (ESD) hazards. Observe precautions for

handling electrostatic sensitive devices

CAUTION, HOT SURFACE: This symbol warns the user of potential hot surfaces

which should be handled with appropriate caution.

Protective Earth (PE) terminal. Provided for connection of the protective earth

(green or green/yellow) supply system conductor.

Functional earth terminal. Used for non-safety purposes such as noise immunity

improvement. NOTE: This connection shall be bonded to protective earth at the

source of supply in accordance with national and local electrical code requirements.

Earth Ground. Functional earth connection. NOTE: This connection shall be bonded

to Protective earth at the source of supply in accordance with national and local

electrical code requirements.

Chassis Ground. Identifies a connection to the chassis or frame of the equipment

shall be bonded to Protective Earth at the source of supply in accordance with

national and local electrical code requirements.

Functional Description

All Controllers

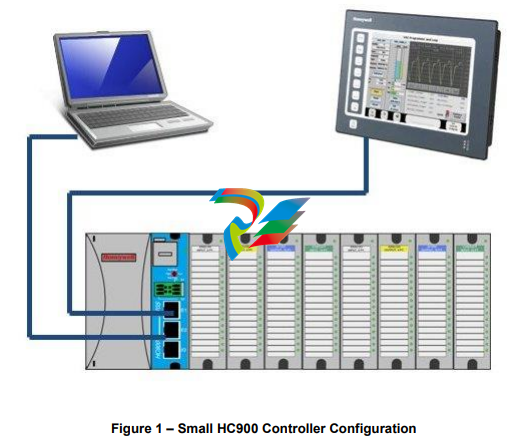

The Honeywell HC900 Process Controller is an integrated loop and logic controller that is designed specifically for

small-and medium-scale unit operations

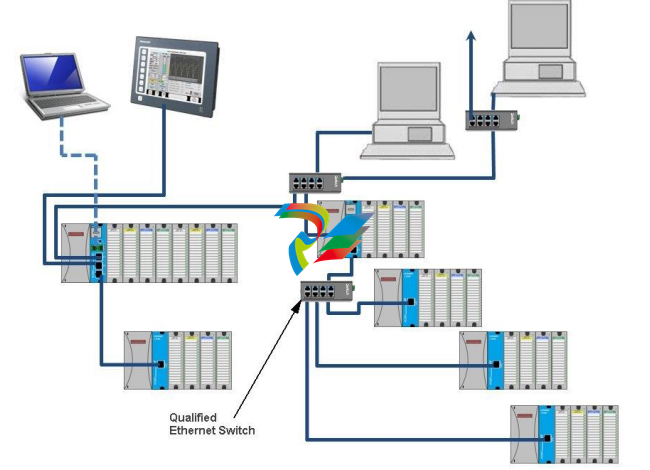

It comprises a set of hardware and software modules that can be assembled to satisfy any of a broad range of process

control applications. The HC900 Process Controller can consist of a single rack, as indicated in Figure 1, or can be

can be networked with other controllers via Ethernet links to expand the dimensions of control over a wider range of

unit processes, as indicated in Figure 2.

Although the HC900 E1/E2 ports provide protection against Cyber-security/DOS type attacks, additional protection

is required for safety applications using a firewall device configured to prevent uncontrolled messages into the

controller. Please refer to Ethernet Devices/Considerations Section in this manual for further information. The

figures in this manual assume the firewall is installed properly above the controller's Ethernet connection(s) E1 and

E2.

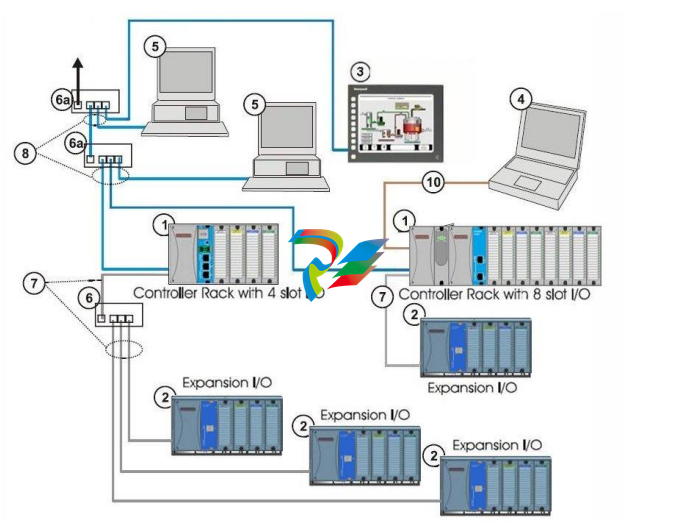

Figure 2 – Expanded HC900 Controller Configuration (C50/C70 CPU only)

The HC900 Controller design enables users and OEMs who are adept in system integration to assemble a system

that fits a broad range of requirements. Any configuration can be readily modified or expanded as requirements

dictate. In initial configuration and in subsequent modifications, the HC900 Controller affords an optimum balance

of performance and economy.

Configurations such as those shown in Figure 1 and in Figure 2, as well as many variations, can be assembled from

modular components. Many of the components are available from Honeywell, and some are available from thirdparty suppliers. These modular components are available in any quantity and mix that make the most sense for a

given application.

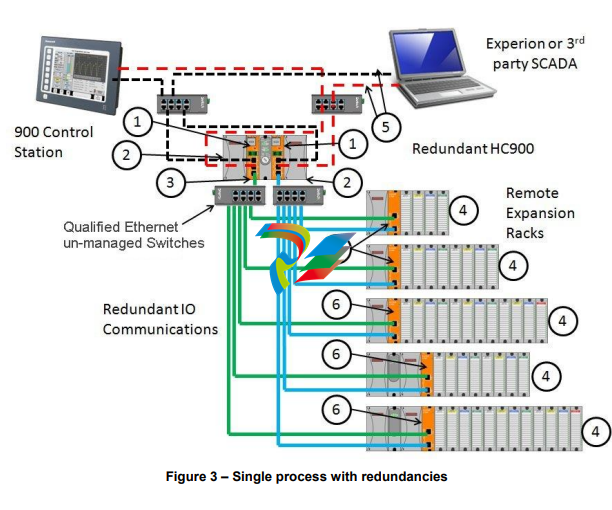

As indicated in Figure 3, the HC900 Controller includes provisions for communication via Ethernet with host

systems such as the Honeywell Experion HMI and other HMI software that supports Ethernet Modbus/TCP

protocol. Also, the communication structure of the HC900 Controller enables remote placement of input/output

components, allowing significant economies in cabling and wiring.

Redundant CPUs - Redundancy is provided by two C75 CPUs operating in a controller rack; this rack has no

I/O. A Redundancy switch module (RSM) sits between the CPUs.

Redundant CPU Power - Two power supplies, P01 and P02 one for each C75 CPU. Model numbers are 900P01-

0101, 900P01-0201, 900P02-0101, 900P02-0201

Redundant CPU-I/O connection – Each CPU has its own 100 base-T Ethernet physical communication link with

one or more racks of I/O. Multiple I/O racks require Ethernet switches.

I/O racks – 5 racks shown, top to bottom: 4-slot w/1 power supply, 8-slot w/1 power supply, 12-slot w/1 power

supply, 8-slot w/redundant power supplies, 12-slot w/redundant power supplies. A Power Status Module (PSM) is

required with redundant power supplies. High and low capacity power supplies are available.

Dual Networks for Host communications - Dual Networks for Host communications are provided on the C75 CPU.

Both network ports are continuously active on the Lead controller. The network ports on the Reserve CPU are not

available for external communications. Experion HS and the 900 Control Station (15 inch model) support Dual

Ethernet communications and automatically transfer communications to the opposite E1/E2 port during a network

failure. Connections to these ports are to be considered part of the control network layer and as such care must be

taken to reduce exposure to uncontrolled/ unknown network communications. A properly configured firewall such as

the MOXA EDR-810 is recommended to help mitigate the exposure.

Scanner 2 module – has 2 ports, one for each CPU connection to I/O. This IO network between the controllers

and scanners is considered proprietary with no other Ethernet traffic.

Feature Summary

Hardware

Modular rack structure; components are ordered individually as needed

CPU with Ethernet and isolated RS485 communications

Easy to assemble, modify, and expand

C30 and C30S controllers provide local I/O connections while C50/C70 and C50S/C70S Controllers provide for

remote input/output rack connections over a private Ethernet-linked network

Parallel processing - a microprocessor in each I/O module performs signal processing, to preserve update rates

Power supplies - provide power to CPU rack and Scanner I/O racks

Redundancy

Redundant C75 CPU

Redundancy Switch Module (RSM) – required between redundant CPUs

Redundant Power Supply – provides redundant power to any CPU rack or Scanner2 I/O rack

Power Status Module (PSM) – required when using a second power supply in Scanner2 I/O rack

Communications

All CPUs (except where noted):

Serial Ports:

Legacy

Two serial ports, configurable for RS-232 or galvanically isolated RS-485 communications.

RS232 port can be used for link to PC for 900 Designer configuration tool (up to 50ft/12.7 Meters)

or via modem. Also can be configured for Modbus RTU, master or slave.

RS 485 port used for 2 wire link to legacy operator interface (ELN protocol) or can be configured

for Modbus RTU, master or slave communications (up to 2000 Ft /600 Meters).

New Controllers

Two isolated RS 485 communications ports

USB to RS485 cable must be obtained to support link to PC for 900 Designer configuration tool

Can be configured for Modbus RTU, master or slave communications (up to 2000 Ft /600 Meters)

Ethernet 10/100 Base-T connection:

Port(s) configured to Auto Negotiate - default to half duplex

C30/C30S controller up to 5 PC hosts via Modbus/TCP protocol. C50/C50S, C70/C70S and

C70R Legacy and C75/C75S (new model) support up to 10 PC hosts via Modbus/TCP protocol.

Peer-to Peer (UDP) communication with up to 32 other HC900 Controllers.

C70/C70S and C70R Legacy and C75/C75S (new model) have 2 Ethernet ports for connection to

up to 10 PC hosts. They also support Modbus/TCP Initiator function over both ports and

automatically switch between ports to maintain Peer to Peer communications with other

C70/C70S or C70R/C75/C75S redundant CPUs.

Private Ethernet 100 base T connection to I/O expansion racks: (except C30 and C30S CPU)

Direct connection to each C70R Legacy and C75/C75S (new model) CPU.

For more information

For complete feature summary and specifications see Specifications on page 206.

Components and Architecture

Overview

This section provides a description of each of the major components that can be included in an HC900 Controller

physical configuration, and indicates some of the methods by which they can be combined.

Components

The Honeywell HC900 Process Controller includes a set of hardware modules that can be combined and configured

as required for a wide range of small to medium process control applications.

Some of the modules are required in all configurations. Others are optional; they are selected as appropriate to

provide optional functions and/or to "size" the system, either in initial planning, or in modifying and/or expanding

the system to meet changing requirements.

An HC900 Controller configuration with multiple controllers is illustrated in Figure 4.

This illustration includes key-numbers that identify components that are described in Table 2

CAUTION

Communications lockout is possible in high network traffic conditions.

Extraneous traffic is possible when sharing bandwidth with other devices. We recommend putting the

controller on a private network segment. Failure to do so could, in high traffic cases, result in

communications lockout requiring the controller to be power-cycled.

Note: The HC900 is equipped with an Ethernet port as a standard feature (two Ethernet ports on the C70

& C75 CPU). These ports can function simultaneously as slave and master communications ports.

The dual Ethernet ports (C70 & C75 CPU’s) can be configured for redundant operation to a host.

If the host device does not have the inherent capability to recognize a network failover, the

Honeywell HWIOPC Server would be used to perform this functionality.

The dual Ethernet ports will not operate in a redundant configuration through a gateway to a

Host / server on another subnet. While both the E1 & E2 Ethernet can be configured with a default

Gateway address, only the E1 port will actually communicate across a gateway to another subnet

Hardware Components

This section contains general descriptions of each of the major components of the HC900 system.

For environmental specifications, refer to the section on Pre-Installation Planning.

HC900 Controller Rack

An HC900 Controller ("local rack") is shown in the following figure. As indicated in this figure, the Controller Rack

includes:

1. Rack, available in 4- 8-, or 12-slot versions

2. Power Supply

3. Controller Module

4. Grounding bars (for I/O wiring; optional)

5. Input/Output modules.

6. I/O Terminal Blocks

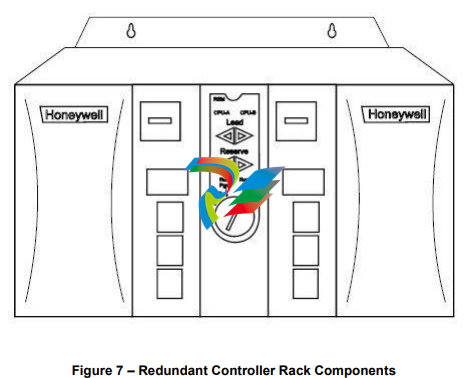

HC900 Redundant Controller Rack

A HC900 Redundant Controller is shown in the following figure.

1. Rack

2. Redundancy Switch Module (RSM) . Interface between Lead/Reserve controllers.

3. Lead/Reserve controllers. Two C75 CPUs, designated “CPU-A” (left), “CPU-B” (right).

4. Two 900P01-xxxx or 900P02-xxxx Power Supplies.