Summary of Installation Instructions for the ABBAC500 product series

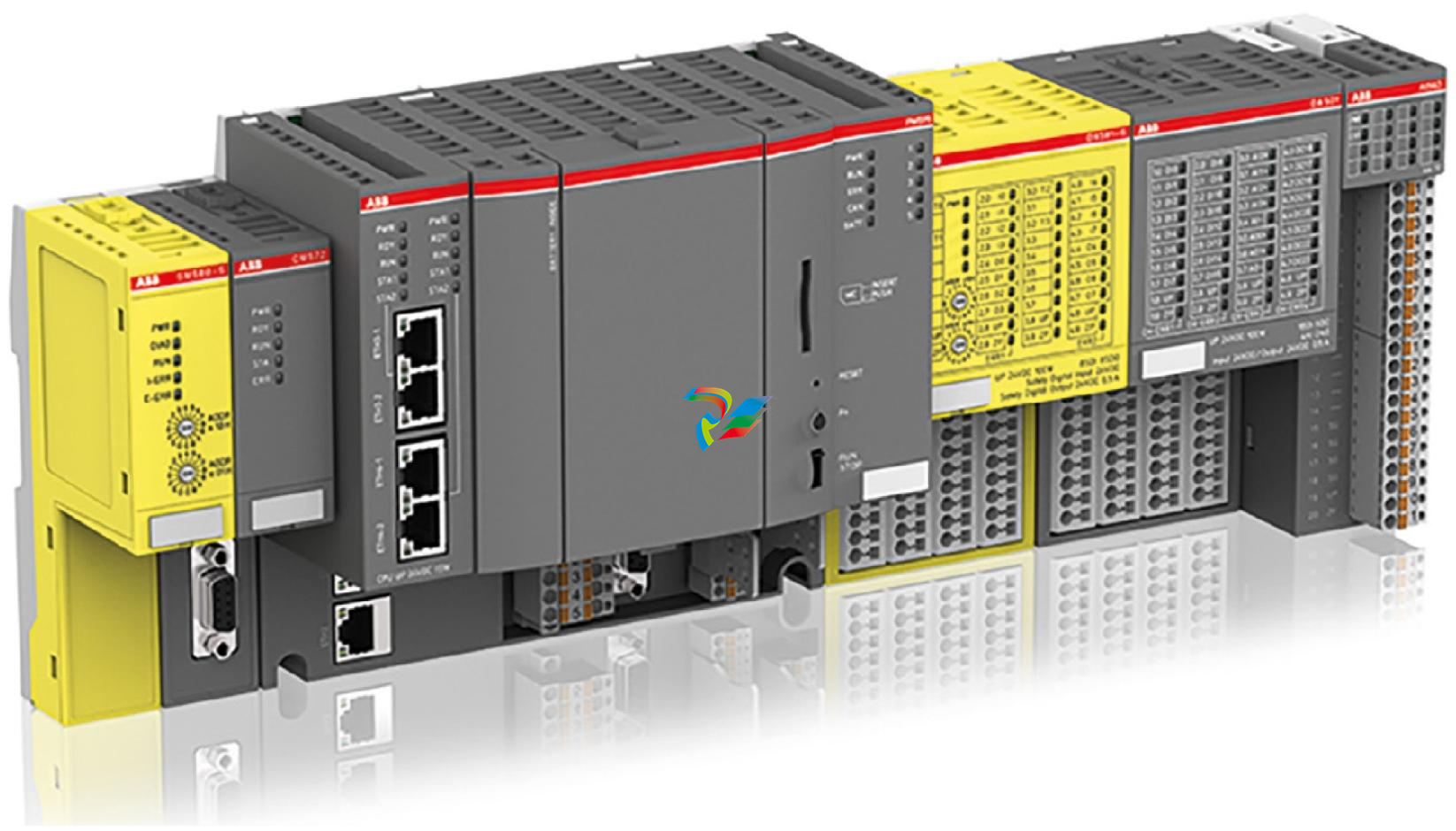

# Summary of AC500 Product Series Installation Instructions This document is an installation guide for ABB AC500 series PLC products, covering assembly, connection, maintenance, and environmental protection requirements for core components such as terminal blocks, processor modules, I/O modules, and communication modules. It is applicable to equipment installation and operation scenarios in industrial automation control systems. ## I. Product Overview The AC500 series is a modular PLC product launched by ABB, covering various functional modules, including **terminal blocks (TB series)**, **processor modules (PM series)**, **digital/analog I/O modules (DC, DI, DO, AI, AO series)**, and **communication modules (CI series)**. The products support modular design, are compatible with hot-swapping (under specific conditions) and extreme environments (XC version), and are widely used in industrial automation control scenarios. ## II. Core Module Types and Functions ### 1. Terminal Block Modules (TB Series) - **Model Examples**: TB51x-TB54x, TB56xx-2ETH - **Functions**: Provide power supply, communication interfaces (Ethernet, ARCNET, CAN), and I/O bus connections, supporting signal transmission between processor modules and external devices. - **Key Features**: Compatible with 19-inch rack mounting, support DIN rail fixing. The XC version is suitable for extreme environments, and unused interfaces need to be protected with TA535 protective covers. ### 2. Processor Modules (PM Series) - **Model Examples**: PM572, PM582, PM595, PM56xx-2ETH - **Functions**: Serve as the core of the control system, support AMP program operation, integrate multiple communication interfaces (Ethernet, COM1/COM2 serial interfaces), and some models support redundant design. - **Key Features**: High-end models such as PM595 support multiple Ethernet interfaces and memory card expansion, and must be used with specific terminal blocks (e.g., PM56xx-2ETH is only compatible with TB56xx-2ETH). ### 3. I/O Modules - **Digital I/O Modules**: DC522, DC523, DC532, DI524, DO524, DO526, etc. They support digital signal input/output with 8-32 channels. The power supply is 24VDC, and they have reverse polarity and overvoltage protection. - **Analog I/O Modules**: AI523, AI531, AO523, AX521, AX522, etc. They support the collection and output of voltage (±10V), current (4-20mA), and temperature signals (Pt100, Ni1000) with 4-16 channels. ### 4. Communication Modules (CI Series) - **Model Examples**: CI5x1 (PROFINET, EtherCAT), CI5x2 (Modbus TCP), CI541-DP/CI542-DP (PROFIBUS) - **Functions**: Expand the system's communication capabilities, support industrial protocols such as PROFINET, PROFIBUS, and Modbus, and realize data interaction with external devices (e.g., frequency converters, sensors). - **Key Features**: Some models support redundant communication, and device addresses need to be set through rotary switches. ## III. General Operation Specifications ### 1. Installation and Disassembly - **Assembly**: Modules are fixed via DIN rails or screws (TA526 wall-mounting accessories must be used to prevent bending). When inserting, align the interface clips to ensure a secure connection. - **Disassembly**: Power must be disconnected first. Some modules need to have clips or screws released. Hot-swappable modules (I/O modules with index F0 and above) can be operated with power on, while processor and communication modules are prohibited from hot-swapping. ### 2. Connection Requirements - **Power Supply**: Most modules use 24VDC power supply (19-31V DC). Terminals are marked as L+ (positive), M (0V), and FE (functional ground), and correct polarity must be ensured. - **Communication Interfaces**: Ethernet interfaces follow TxD±/RxD± pin definitions; PROFIBUS interfaces need to pay attention to RxD/TxD-P/N signals; serial interfaces (RS-232/RS-485) must be connected according to pin assignments (e.g., RTS, TxD, RxD signals of COM1). - **I/O Signals**: For digital signals, distinguish between input (DI)/output (DO) terminals; for analog signals, pay attention to positive and negative poles (e.g., AIx+/- of AI modules) to avoid short circuits or reverse connections. ### 3. Maintenance and Cleaning - **Cleaning**: Only wet rags are allowed for wiping; cleaning agents are prohibited to prevent corrosion of electronic components. - **Troubleshooting**: Determine the status through module LED indicators (e.g., PWR/RUN light indicates power and operation status, ERR light indicates errors). For extreme environments (XC version), regularly check interface protection. ## IV. Technical Characteristics and Safety Requirements ### 1. Special Function Support - **Hot-Swapping**: Only applicable to I/O modules with index F0 and above, which must be matched with TU5xx-H terminal devices. Processors and communication modules are prohibited from hot-swapping with power on. - **Extreme Environment (XC Version)**: Suitable for harsh environments such as salt spray. Unused interfaces must be protected with TA535 protective covers to avoid corrosion. ### 2. Safety Specifications - **Operation Qualification**: Installation and maintenance must be performed by professional electricians in accordance with standards such as EN 60204-1. - **Protection Measures**: I/O channels have reverse polarity and overvoltage protection (30VDC continuous overvoltage); power and communication lines must be shielded and grounded to reduce electromagnetic interference. ## V. Certification and Environmental Requirements ### 1. Certification Modules comply with multiple international standards, including: - Electromagnetic Compatibility (EMC): EN 61000-6-2 (industrial immunity), EN 61000-6-4 (industrial emission standards); - Regional Certifications: KCC (South Korea), MSIP-REI (international), etc., with the label "MSIP-REI-Abb-AC500". ### 2. Recycling and Environmental Protection - Products and packaging are marked with the WEEE Directive symbol and must be recycled separately from domestic waste, handled by designated WEEE facilities; - Materials are recyclable, and users must contact local environmental protection departments or recycling agencies to dispose of waste equipment. ## Summary The AC500 series takes modularization and high compatibility as its core advantages, covering all scenarios of industrial control needs. Installation and operation must strictly follow safety specifications, with attention to module compatibility (e.g., matching of processors and terminal blocks), hot-swapping conditions, and protection in extreme environments. Compliant installation and maintenance can ensure stable system operation while meeting environmental protection and certification requirements.