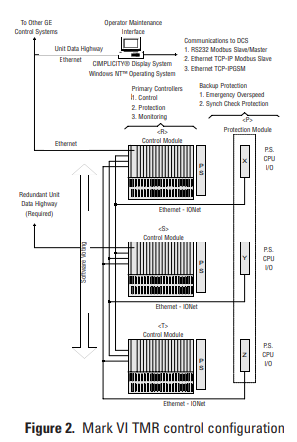

GESPEEDTRONIC™ Mark VI Turbine Control System

own” IONet.

Data from the VCMI cards in each of the three

Control Modules is then exchanged and voted

prior to transmitting the data to the main

processor cards for execution of the application

software. Output voting is extended to the turbine with three coil servos for control valves and

2 out of 3 relays for critical outputs such as

hydraulic trip solenoids. Other forms of output

voting are available, including a median select

of 4-20ma outputs for process control and 0-

200ma outputs for positioners.

Sensor interface for TMR controls can be either

single, dual, triple redundant, or combinations

of redundancy levels. The TMR architecture

supports riding through a single point failure in

the electronics and repair of the defective card

or module while the process is running. Adding

sensor redundancy increases the fault tolerance

of the overall “system.” Another TMR feature is

the ability to distinguish between field sensor

faults and internal electronics faults.

Diagnostics continuously monitor the 3 sets of

input electronics and alarms any discrepancies

between them as an internal fault versus a sensor fault. In addition, all three main processors

continue to execute the correct “voted” input

data. (See Figure 2.)

I/O Interface

There are two types of termination boards. One

type has two 24-point, barrier-type terminal

blocks that can be unplugged for field maintenance. These are available for Simplex and

TMR controls. They can accept two 3.0 mm2

(#12AWG) wires with 300 volt insulation.

Another type of termination board used on

Simplex controls is mounted on a DIN rail and

has one, fixed, box-type terminal block. It can

accept one 3.0 mm2 (#12AWG) wire or two 2.0

mm2 (#14AWG) wires with 300 volt insulation.

I/O devices on the equipment can be mounted

up to 300 meters (984 feet) from the termination boards, and the termination boards must

be within 15 m (49.2’) from their corresponding I/O cards. Normally, the termination

boards are mounted in vertical columns in termination cabinets with pre-assigned cable

lengths and routing to minimize exposure to

emi-rfi for noise sensitive signals such as speed

inputs and servo loops.

General Purpose I/O

Discrete I/O. A VCRC card provides 48 digital

inputs and 24 digital outputs. The I/O is divided between 2 Termination Boards for the contact inputs and another 2 for the relay outputs.

(See Table 1.)

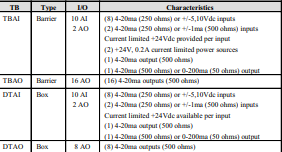

Analog I/O. A VAIC card provides 20 analog

inputs and 4 analog outputs. The I/O is divided

between 2 Termination Boards. A VAOC is dedicated to 16 analog outputs and interfaces with

1 barrier-type Termination Board or 2 box-type

Termination Boards. (See Table 2.)

Temperature Monitoring. A VTCC card provides interface to 24 thermocouples, and a

VRTD card provides interface for 16 RTDs. The

input cards interface with 1 barrier-type

reduced by eliminating peripheral instrumentation. The VTUR card is designed to integrate

several of the unique sensor interfaces used in

turbine control systems on a single card. In

some applications, it works in conjunction with

the I/O interface in the Backup Protection

Module described below.

Speed (Pulse Rate) Inputs. Four-speed inputs

from passive magnetic sensors are monitored by

the VTUR card. Another two-speed (pulse rate)

inputs can be monitored by the servo card

VSVO which can interface with either passive or

active speed sensors. Pulse rate inputs on the

VSVO are commonly used for flow-divider feedback in servo loops. The frequency range is 2-

14k Hz with sufficient sensitivity at 2 Hz to

detect zero speed from a 60-toothed wheel. Two

additional passive speed sensors can be monitored by “each” of the three sections of the

Backup Protection Module used for emergency

overspeed protection on turbines that do not

have a mechanical overspeed bolt. IONet is

used to communicate diagnostic and process

data between the Backup Protection Module

and the Control Module(s) including cross-tripping capability; however, both modules will initiate system trips independent of the IONet.

(See Table 4 and Table 5.)

Synchronizing. The synchronizing system consists of automatic synchronizing, manual synchronizing, and backup synch check protection. Two single-phase PT inputs are provided

Application Specific I/O

In addition to general purpose I/O, the Mark

VI has a large variety of cards that are designed

for direct interface to unique sensors and actuators. This reduces or eliminates a substantial

amount of interposing instrumentation in

many applications. As a result, many potential

single-point failures are eliminated in the most

critical area for improved running reliability

and reduced long-term maintenance. Direct

interface to the sensors and actuators also

enables the diagnostics to directly interrogate

the devices on the equipment for maximum

effectiveness. This data is used to analyze device

and system performance. A subtle benefit of

this design is that spare-parts inventories are

on the TTUR Termination Board to monitor

the generator and line busses via the VTUR

card. Turbine speed is matched to the line frequency, and the generator and line voltages are

matched prior to giving a command to close the

breaker via the TTUR.

An external synch check relay is connected in