GESPEEDTRONIC™ Mark VI Turbine Control System

sources are provided for each Pyrometer that

returns four 4-20ma inputs. Two Keyphasors are

used for the shaft reference. The VPYR and

matching TPYR support 5,100 rpm shaft speeds

and can be configured to monitor up to 92 buckets with 30 samples per bucket. (See Table 10.)

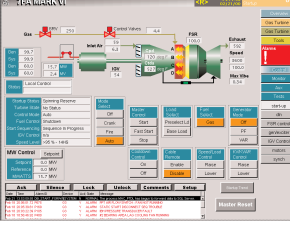

Operator Interface

The operator interface is commonly referred to

as the Human Machine Interface (HMI). It is a

PC with a Microsoft® Windows NT® operating

system supporting client/server capability, a

CIMPLICITY® graphics display system, a

Control System Toolbox for maintenance, and a

software interface for the Mark VI and other

control systems on the network. (See Figure 3.)

It can be applied as:

■ The primary operator interface for

one or multiple units

■

■ A backup operator interface to the

plant DCS operator interface

■ A gateway for communication links to

other control systems

■ A permanent or temporary

maintenance station

■ An engineer’s workstation

All control and protection is resident in the

Mark VI control, which allows the HMI to be a

non-essential component of the control system.

It can be reinitialized or replaced with the

process running with no impact on the control

system. The HMI communicates with the main

processor card in the Control Module via the

Ethernet based Unit Data Highway (UDH). All

analog and digital data in the Mark VI is accessible for HMI screens including the high resolution time tags for alarms and events.

System (process) alarms and diagnostics alarms

for fault conditions are time tagged at frame

rate (10/20/40 ms) in the Mark VI control and

transmitted to the HMI alarm management system. System events are time tagged at frame

rate, and Sequence of Events (SOE) for contact

inputs are time tagged at 1ms on the contact

input card in the Control Module. Alarms can

be sorted according to ID, Resource, Device,

Time, and Priority. Operators can add comments to alarm messages or link specific alarm

messages to supporting graphics.

Data is displayed in either English or Metric

engineering units with a one-second refresh

rate and a maximum of one second to repaint a

typical display graphic. Operator commands

can be issued by either incrementing / decrementing a setpoint or entering a numerical

value for the new setpoint. Responses to these

commands can be observed on the screen one

second from the time the command was issued.

Security for HMI users is important to restrict

access to certain maintenance functions such as

editors and tuning capability, and to limit certain operations. A system called “User

Accounts” is provided to limit access or use of

particular HMI features. This is done through

the Windows NT User Manager administration

program that supports five user account levels.

Software Maintenance Tools

The Mark VI is a fully programmable control

system. Application software is created from inhouse software automation tools which select

proven GE control and protection algorithms

and integrate them with the I/O, sequencing,

and displays for each application. A library of

software is provided with general-purpose

blocks, math blocks, macros, and application

specific blocks. It uses 32-bit floating point data

(IEEE-854) in a QNX operating system with

real-time applications, multitasking, prioritydriven preemptive scheduling, and fast context

switching.

Software frame rates of 10, 20, and 40 ms are

supported. This is the elapsed time that it takes

to read inputs, condition the inputs, execute

the application software, and send outputs.

Changes to the application software can be

made with password protection (5 levels) and

downloaded to the Control Module while the

process is running. All application software is

stored in the Control Module in non-volatile

flash memory.

Application software is executed sequentially

and represented in its dynamic state in a ladder

diagram format. Maintenance personnel can

add, delete, or change analog loops, sequencing logic, tuning constants, etc. Data points can

be selected and “dragged” on the screen from

one block to another to simplify editing. Other

features include logic forcing, analog forcing,

and trending at frame rate. Application software documentation is created directly from

the source code and printed at the site. This

includes the primary elementary diagram, I/O

assignments, the settings of tuning constants,

etc. The software maintenance tools (Control

System Toolbox) are available in the HMI and

as a separate software package for virtually any

Windows 95 or NT based PC. The same tools

are used for EX2000 Generator Excitation

Systems, and Static Starters. (See Figure 4 and

Figure 5.)

Communications

Communications are provided for internal data

transfer within a single Mark VI control; communications between Mark VI controls and

peer GE control systems; and external communications to remote systems such as a plant distributed control system (DCS).

The Unit Data Highway (UDH) is an Ethernetbased LAN with peer-to-peer communication

between Mark VI controls, EX2000 Generator

Excitation Controls, Static Starters, the GE

Fanuc family of PLC based controls, HMIs, and

Historians. The network uses Ethernet Global

Data (EGD) which is a message-based protocol

with support for sharing information with mul