GESPEEDTRONIC™ Mark VI Turbine Control System

series with the internal K25P synch permissive

relay and the K25 auto synch relay via the

TTUR. Feedback of the actual breaker closing

time is provided by a 52G/a contact from the

generator breaker (not an auxiliary relay) to

update the database. An internal K25A synch

check relay is provided on the TTUR; however,

the backup phase / slip calculation for this relay

is performed in the Backup Protection Module

or via an external backup synch check relay.

Manual synchronizing is available from an operator station on the network or from a synchroscope.

Shaft Voltage and Current Monitor. Voltage can

build up across the oil film of bearings until a

discharge occurs. Repeated discharge and arcing can cause a pitted and roughened bearing

surface that will eventually fail through accelerated mechanical wear. The VTUR / TTUR can

continuously monitor the shaft-to- ground voltage and current, and alarm at excessive levels.

Test circuits are provided to check the alarm

functions and the continuity of wiring to the

brush assembly that is mounted between the

turbine and the generator.

F

Flame Detection. The existence of flame either

can be calculated from turbine parameters that

are already being monitored or from a direct

interface to Reuter Stokes or Honeywell-type

flame detectors. These detectors monitor the

flame in the combustion chamber by detecting

UV radiation emitted by the flame. The Reuter

Stokes detectors produce a 4-20ma input. For

Honeywell flame scanners, the Mark VI supplies

the 335Vdc excitation and the VTUR / TRPG

monitors the pulses of current being generated.

This determines if carbon buildup or other

contaminates on the scanner window are causing reduced light detection.

Trip System. On turbines that do not have a

mechanical overspeed bolt, the control can

issue a trip command either from the main

processor card to the VTUR card in the Control

Module(s) or from the Backup Protection

Module. Hydraulic trip solenoids are wired with

the negative side of the 24Vdc/125Vdc circuit

connected to the TRPG, which is driven from

the VTUR in the Control Module(s) and the

positive side connected to the TREG which is

driven from the VPRO in each section of the

Backup Protection Module. A typical system trip

initiated in the Control Module(s) will cause

the analog control to drive the servo valve actuators closed, which stops fuel or steam flow and

de-energizes (or energizes) the hydraulic trip

solenoids from the VTUR and TRPG. If crosstripping is used or an overspeed condition is

detected, then the VTUR/TRPG will trip one

side of the solenoids and the VPTRO/TREG

will trip the other side of the solenoid(s).

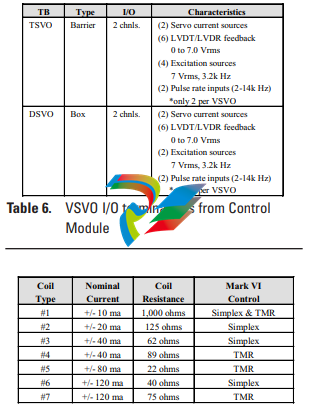

Servo Valve Interface. A VSVO card provides 4

servo channels with selectable current drivers,

feedback from LVDTs, LVDRs, or ratio metric

LVDTs, and pulse-rate inputs from flow divider

feedback used on some liquid fuel systems. In

TMR applications, 3 coil servos are commonly

used to extend the voting of analog outs to the

servo coils. Two coil servos can also be used.

One, two, or three LVDT/Rs feedback sensors

can be used per servo channel with a high select,

low select, or median select made in software. At

least 2 LVDT/Rs are recommended for TMR

applications because each sensor requires an AC

excitation source. (See Table 6 and Table 7.)

Vibration / Proximitor® Inputs. The VVIB card

provides a direct interface to seismic (velocity),

Proximitor®, Velomitor®, and accelerometer

(via charge amplifier) probes. In addition, DC

position inputs are available for axial measurements and Keyphasor® inputs are provided.

Displays show the 1X and unfiltered vibration

levels and the 1X vibration phase angle. -24vdc

is supplied from the control to each Proximitor

with current limiting per point. An optional termination board can be provided with active isolation amplifiers to buffer the sensor signals

from BNC connectors. These connectors can be

used to access real-time data by remote vibration analysis equipment. In addition, a direct

plug connection is available from the termination board to a Bently Nevada 3500 monitor.

The 16 vibration inputs, 8 DC position inputs,

and 2 Keyphasor inputs on the VVIB are divided between 2 TVIB termination boards for

3,000 rpm and 3,600 rpm applications. Faster

shaft speeds may require faster sampling rates

on the VVIB processor, resulting in reduced

vibration inputs from 16-to-8. (See Table 8.)

Three phase PT and CT monitoring. The VGEN

card serves a dual role as an interface for 3

phase PTs and 1 phase CTs as well as a specialized control for Power-Load Unbalance and

Early-Valve Actuation on large reheat steam turbines. The I/O interface is split between the

TGEN Termination Board for the PT and CT

inputs and the TRLY Termination Board for

relay outputs to the fast acting solenoids. 4-

20ma inputs are also provided on the TGEN for

monitoring pressure transducers. If an EX2000

Generator Excitation System is controlling the

generator, then 3 phase PT and CT data is communicated to the Mark VI on the network

rather than using the VGEN card. (See Table 9.)

Optical Pyrometer Inputs. The VPYR card moni

tors two LAND infrared pyrometers to create a

temperature profile of rotating turbine blades.

Separate, current limited +24Vdc and –24Vdc