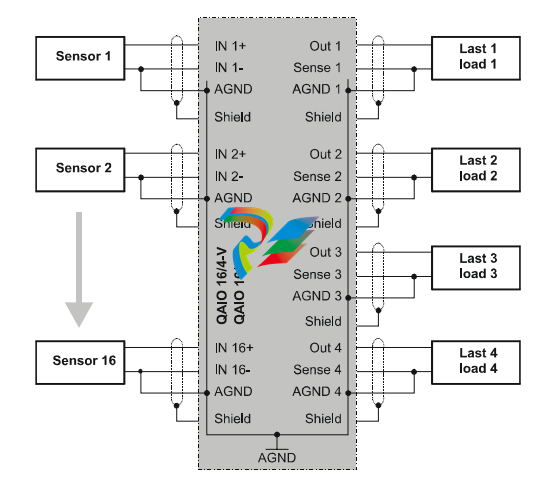

MOOGUser Manual M3000® Control System QAIO 16/4 Analog I/O Extension Module

circuits can cause serious damage to the module or permanently impair measuring accuracy.

2.7.2. Commissioning

All connections should be re-checked for correct wiring and polarity the supply

voltage is applied.

The handling of the module depends on the software environment used. For this

reason, you should consult the information in the programming manuals for the

CP1131 or CPC++, as appropriate.

2.7.3. Initialisation and module identification

The analog expansion module is identified and initialised by the operating system of

the upstream Cell Controllers. The identification characteristics stored in the module

are evaluated by the Cell Controller for this purpose.

No dip switch settings are required. In the case of failure of the +24 V power supply

or interruption of the E bus transmission, the analog outputs are reset to 0 V

(LED “OUT_ENA”).

2.7.4. Measuring

The measurements and transfer of the data from the module to the CAN node are

carried out in a cyclic manner, controlled via the API (Application Process Interface)

in the operating system. No start signals have to be output for AD conversion.

Execution of the measuring process depends on the software environment used.

For this reason, you should consult the relevant information contained in the programming manuals for CP1131 or CPC++.

Note::

The following formula applies for converting the measured data into voltage

values:

AD AD U = 10 V 215 I = 20 mA 215

Comment: AD = the value supplied by the analog channel (in_value)

When leaving the permissible measuring range, the following values are reported:

Exceeding the permissible measuring range (+) + 32752 + 9,995 V

Falling short of the permissible measuring range (-) - 32768 - 10,000 V

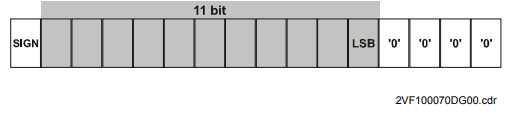

Representation of the 11-bit measured value with sign in a 16-bit variable:

Sensor failure

In the case of sensor failure, the corresponding channel reports the value for

+9.995 V to the cell controller.

2.7.6. Connection of sensors/actuators

Sensor connection, examples

Note:

The measuring line shield can, where required, be

connected to SHIELD.

Where better HF contact of the shields is possible

at another point in the casing, there should be no

additional connection to SHIELD on the module.

2VF100069DG00.cdr

Floating sensors

Connection via 2-pole, shielded cable (IN+/AGND). In the case

of floating sensors, at least one of the measuring inputs (IN -)

must be bridged to AGND

The cancellation of electrical isolation brought about by the bridge is absolutely

necessary as capacitive signal couplings with impermissibly high common mode

voltages are already built up because of the very high impedance inputs. This

leads to sporadic incorrect measurements which are difficult to detect in most

cases.

2VF100066DG00.cdr

Potential-afflicted sensors with auxiliary power connection

Connection via 2-pole, shielded cable (IN+/IN-). Sensors with

auxiliary power supply but without electrical isolation should be

operated from the same power supply source as the module.

The sensor is connected to the two measuring inputs IN+ and

IN- in the required polarity. The AGND connection of the module

remains open.

It is to be ensured that the potential equalisation via the common supply and

sensors actually occurs.

2VF100067DG00.cdr

Sensor connection using internal module reference voltage

Connection via 3 or 4-pole shielded cable (IN+/IN-/URef/AGND).

Radiometric sensors (potentiometer, bridge circuits) are treated

as potential-afflicted sensors.

The auxiliary power is also carried in the measuring line.

If only one measuring input is needed, as in the case of the potentiometer connection, the free input must be bridged to AGND.

It must be ensured that the reference voltage is not overloaded and that the current taken from the reference source can flow back again via the AGND connections.

.png)

.png)

.png)