ABBDCV 700 thyristor panelsfor 6-/ and 12-pulse DC drive systems in Drive-MNS-cabinets 22 to 5150/10300 A 10 to 4900/9400 kW

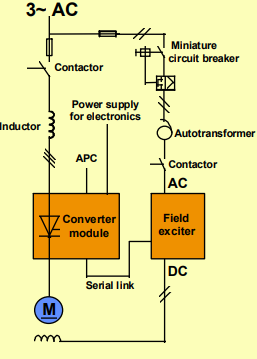

Control Configuration The control system provides a flexible and simple method of controlling different drive configurations. The configurations comprise the converter and its software, Application Controller, Engineering and Maintenance tools and different communication links to other automation systems. The control system includes an Application Controller (APC) and a Digital Drive Controller (DDC) with well defined functions and interface. The Application Controller (APC), common for both AC and DC drives, is a single board controller with all the software and hardware facilities needed to handle the application specific functions. The Digital Drive Controller (DDC) is not programmable but various functions and operating modes can be selected by a fixed number of parameters, which are set from the APC level. The motor control programs are located in the DDC, which is controlled by either a torque or a speed reference provided by the APC.

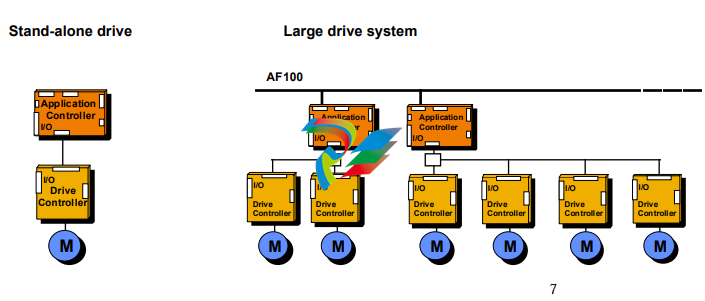

Stand-alone drive A single drive has one Digital Drive Controller DDC connected to the Application controller APC. Small drive system In small systems, one APC is connected from 1 up to 4 Digital Drive Controllers. The small drive configuration can also be used in master/slave applications. Large drive system Large systems are built by interconnecting application controllers through a communication bus, for example AF100. Common control functions can be distributed to separate nodes. Even very complex systems can be configured by using the same system design concept and its common building blocks, resulting in great savings in, for example, spare parts.

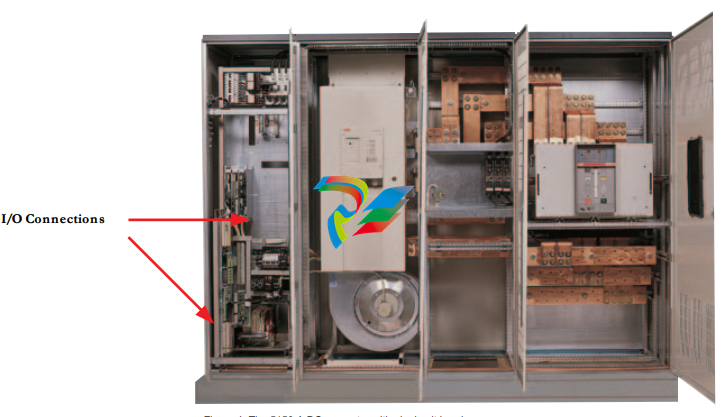

The I/O connections of the DCV 700 are in the Application Controller (APC) and in the Digital Drive Controller (DDC). The Application Controller APC includes: • 4 digital inputs • 2 digital outputs • 2 analogue inputs • 1 voltage reference output The I/O connections in the Drive Controller DDC are used for safety and other drive specific functions like emergency stop and motor temperature measurement: • 3 digital inputs • 4 digital outputs • 5 analogue inputs • 2 analogue outputs • 1 pulse encoder input • 1 emergency stop input • 1 emergency stop output • 1 current source • 1 voltage reference output • 1 actual armature current output Optional I/O boards are available to provide tailored solutions for the most demanding applications. The quantity of I/Os can be increased by using extended I/O board and speed measurement board. Extended / Remote I/O Board YPQ110A Connection to the APC can either be through parallel bus (extended) or through low speed serial bus (remote). • 8 digital inputs • 8 digital outputs • 4 analogue inputs • 2 analogue outputs • 3 voltage reference outputs Speed Measurement Board YPH107A The board can be used for accurate speed and position measurement. Connection to the APC is through the parallel bus. For positioning there is a 32 bit hardware counter. • 1 digital input for synchronisation • 1 pulse encoder input • 2 analogue outputs

Communication Various communication boards are available to provide communication links between the APC and overriding control systems.

AF100 Advant Fieldbus 100 is a high-speed serial bus, which is used for communication between APCs or between an APC and an overriding system such as ABB’s Advant Controller AC400-family. The bus administrator board CI626 (BA) is needed for controlling the bus when not using the Advant Controller AC450. The communication board YPK112A is used to connect the APC to the Advant Fieldbus 100.

UART Board YPK113A The UART board, YPK113A, is used to communicate with other overriding systems. Protocols for Siemens Simatic S5 and Allen Bradley DH are available together with SAMI protocol.

Technical Data Optional I/O Connections The technical data and dimensions are valid at the time of printing. We reserve the right to subsequent alterations. Extended/Remote I/O board YPQ110A

8 digital inputs Opto isolated inputs, control voltage 110 VAC/ 24 VDC. Hardware delay 2 ms. Digital filter time constants from 0.5 ms to 128 ms in 0.5 ms steps. Input impedance 3 kΩ for 24 VDC and 13 kΩ for 110 VAC. 8 digital outputs 6 relay outputs, normally open contacts. Max. voltage 230 VAC, max. current 2 A at 230 VAC, min. switching time 20 ms. 2 opto isolated transistor outputs. Max. voltage 60 V DC, max. current 100 mA, min. switching time 100 µs. 4 analogue inputs Differential inputs, resolution 12 bits+sign. Input ranges -10 to +10 V or -20 to +20 mA (0 to +10 V, 0 to +1 V and 0/4 to 20 mA by software scaling), input impedance is 400 kΩ. Accuracy ± 0.1 % at ± 10 V and ± 0.4 % at ± 1 V. Hardware filter time constant 5 ms. Digital filter time constants from 5 ms to 32 s in 1 ms steps. 2 analogue outputs Output voltage -10 to +10 V, output current -10 to +10 mA. Resolution 12 bits+sign, accuracy ± 0.1 %. 3 voltage reference +10 V voltage reference, accuracy ± 1 mV. outputs Max. load current 10 mA. -10 V voltage reference, accuracy ± 5 mV. Max. load current 10 mA. 5 mA current reference, accuracy ± 0.05 mA. Max. load resistance 1 kΩ. Extended, connection through parallel bus: max. 4 boards. Remote, connection through low speed serial bus: max. 8 nodes. Speed measurement board YPH107A 1 digital input for Control voltage 24 V AC/DC or 110 V AC/DC. synchronisation Input impedance 3 kΩ at 24 V and 13 kΩ at 110 V. Hardware delay 1 ms or 10 ms, software adjustable. 1 pulse encoder input 3 opto isolated channels (A, B and Z), differential or single ended tachometers. ± 13 mA current input or ± 24 V voltage input. Max. input frequency 300 kHz. 2 analogue outputs Output voltage ± 10 V, output current ± 10 mA. Resolution 12 bits, accuracy ± 1 %.