ABBDevice Management PROFIBUS DP/FMS Redundancy Link Module, RLM01

Section 1 Features/ Application

RLM 01 converts one simple, non-redundant Profibus line into two reciprocally redundant lines A/B. The module works bidirectionally, which means that all three interfaces can receive and transmit data

• Conversion: Line M <=> Lines A/B

• Use on PROFIBUS DP/FMS lines

• Automatic line selection

• Transmission rate 9.6 kBit/s .... 12 MBit/s

• Monitoring of communication

• Repeater functionality

• Redundant power supply

• Status and error display

• Monitoring of the power supply

• Potential-free alarm contact

• Simple assembly on DIN mounting rail

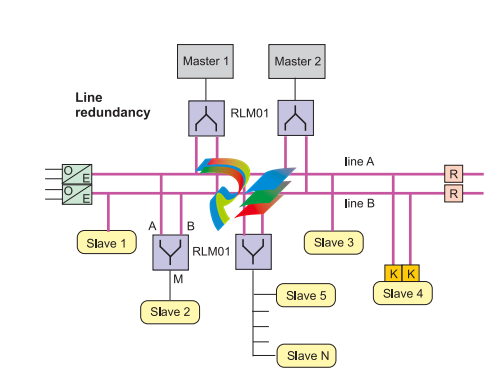

You can position the module directly after a master, before a bus segment with several slaves or before an individual slave. PROFIBUS stations with redundant couplers [K] can be directly connected to the PROFIBUS set redundant by RLM 01. Stations with only one interface can be optionally assigned to the A or B line. Each RLM 01 PROFIBUS interface can serve up to 31 PROFIBUS stations. Using repeaters [R] and media converters [O/E] makes it possible to increase the length of the PROFIBUS lines and the number of stations.

Figure 1. Application example

RLM01 does not support master redundancy where one master only runs line A and the other one only line B. The bus communication is asynchronous, even if both masters balance their program modules against each other on the applicational level. A Melody central unit CMC 60/70 offers clock sy

Network devices like repeater, FOC coupler, DP/PA converter as well as RLM01 cause a N x bit time delay of data telegrams. The delay time (see technical data) is device specific and depends upon the selected baud rate. It must be taken into consideration for the master bus configuration.

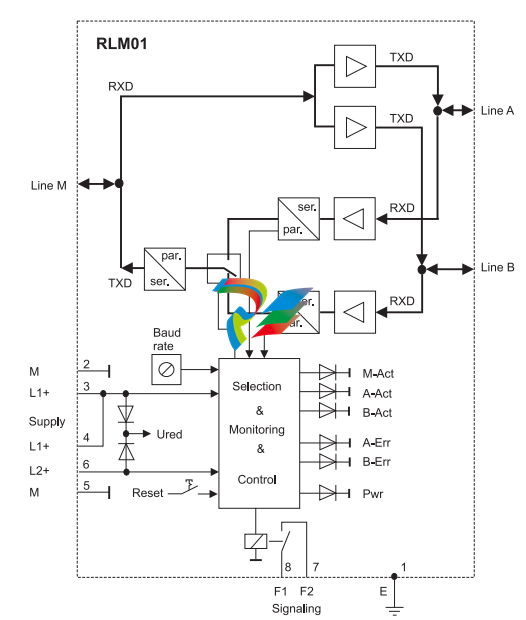

Section 2 Description of functions

The three RS 485 interfaces of the module support all transmission rates specified in DIN 19245 for the PROFIBUS from 9.6 kBit/s to 12 MBit/s. The module has repeater functionality, i.e., it regenerates the signal shape and the amplitude of received data. RLM 01 monitors all three lines A, B and M for activity and error states. Detected errors are signalled by lit diodes on the front panel. The potentialfree alarm contact activated in parallel to this can be polled for diagnostic purposes by the process control system PCS or by a programmable logic control PLC. The three serial RS 485 interfaces are potential-free relative to each other and to the power supply. This is a functional electrical isolation. The first data coming in over line A or line B with a correct telegram start are routed to terminal M. With simultaneity, either line A or line B is selected at random. Testing and selection is always based on the first character. In the case of a telegram start with error on A, the control logic switches to the redundant line B. The same procedure applies vice-versa for line B. Data coming in over line M with a correct telegram start are routed in parallel to the two terminals A and B. The test for data is always based on the first character. In the case of a telegram start with error, the control logic does not output any data to A and B. Either a single or a redundant power supply with 24 VDC is possible. The distribution of load across L1+ and L2+ is based on the level of the voltages applied. If a voltage source fails, the switch to the redundant supply source is made without interruption. A monitoring logic circuit tests whether both voltages are present.

Section 3 Commissioning

Safety information

To supply RLM 01, use only a safety-low voltage. This requirement also applies to the alarm contact supply. In accordance with the UL/CSA requirements an external protection (e.g. fuse) is prescribed. The fuse rating can amounted to 1.6A to 10A (characteristic: medium slow-acting or slow-acting). Protection of groups of several devices with a common fuse is admissible (several RLM 01 or RLM 01 together with other devices). When selecting a mounting location, make certain that the limit values for ambient conditions specified in the technical data are observed and the module can discharge heat without any obstruction. Do not connect any bus lines that are laid partially or entirely outside buildings. Voltage overload, for example resulting from lightning strikes, may destroy the module. For protection against cases such as these, use optical fibre cable and appropriate medium converters (electrical <==> optical) as high-quality electrical isolation. In accordance with the PROFIBUS installation guideline the shielding of the bus cables are preferably connected at the start and at the end with earth potential. Place the module on a low-resistance and low-inductance earthed DIN mounting rail. Grounding measures by way of the E terminal (1) on the terminal strip are then not required.

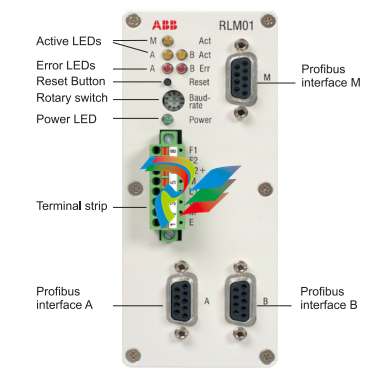

Front panel elements

Three Sub-D connectors A, B and M are located on the front panel of the RLM 01 for connection of the PROFIBUS cable. The 8-pin male multi-pin connector with the associated terminal strip is used to connect the alarm and power supply wires. There are also LEDs for activity/error display, a rotary switch for setting the transmission rate and a reset button (activate transmission rate)

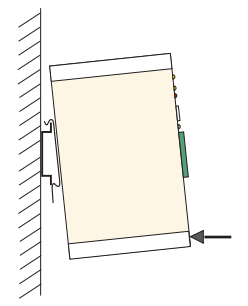

Mounting

The module should preferably be attached vertically on a DIN mounting rail. To do this, place the two rear-side clamps on the top edge of the mounting rail. Then press lightly on the underside of the module until the clamps spread apart and the bottom edge of the rail locks audibly into place. The mounting location should be selected so that the RLM 01 can discharge heat arising from power loss without hindrance. A

distance of > 30 mm should be maintained between the top/bottom of the module and cable ducts, other devices, etc.

Installation

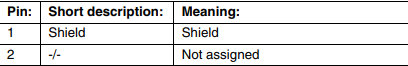

The redundant PROFIBUS lines are connected to the two terminals A and B. Terminal M is provided for the non-redundant PROFIBUS line. All three PROFIBUS connections A, B and M are designed uniformly with 9-pin Sub-D connectors (sockets). The pin assignment conforms to the PROFIBUS standard. RLM 01 uses only pins 3+8 for data transfer and 6+5 for power supply to an external resistor combination for bus termination. The following table shows the maximum assignment for PROFIBUS usage

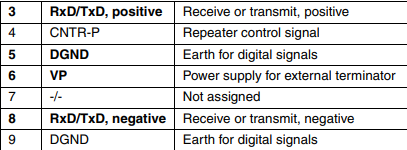

If terminals A/B of RLM 01 are positioned at the beginning or end of a bus segment, two terminals must be provided with one bus termination each (resistor combination). The same also applies for terminal M if it is located at the beginning or the end of a PROFIBUS segment. It is preferable to use PROFIBUS terminals with an integrated resistor combination that can be turned on and off. A shortcircuit-proof power supply to supply the resistors located in the connector is available on pins 5 (VP+) and 6 (DGND). The designation A/B in the following figure refers to the cables in the PROFIBUS cable and not to the redundant PROFIBUS cables, which are also named A/B.

Use only shielded PROFIBUS connectors of suitable design. The connectors should preferably have a cable connection that is angled down at 35° and is no wider than 18 mm.

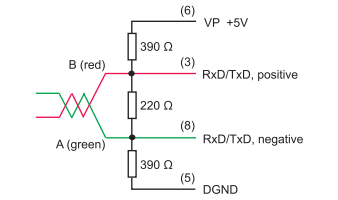

The power supply and alarm lines are connected directly to the terminals labelled 1 to 8. If it is necessary to replace the module, you need only remove the terminal strips. The maximum of 8 cables remain connected. The functions of terminals 1... 8 are given in the following table.

You can press down the orange-coloured pin using a narrow screwdriver to open the cage tension spring. Only press the pin in far enough to feel a noticiable resistance ( about 1 mm below the upper surface of the terminal strip ). Now insert the stripped wire as far as it will go into the large hole on the left. Reliable contact is only ensured if the cage tension spring grasps the wire and not the insulation around it. The cage tension spring can receive solid wires or rough wire strands with cross sections from 0.14 to 1.5 mm2. Please use flexible or rough wire strands with the lowest possible cross section for better handling and reduced mechanical stress to the terminal strip.

Setting the baud rate

Configuration of the RLM 01 merely involves setting the baud rate. It should be set with the rotary switch on the front panel before turning on the power supply. You can select baud rates of from 9.6 kbd to 12 Mbd. If the baud rate is changed during ongoing operation, you should push the reset button once briefly to reset the control logic and the counters etc. to a defined initial state.

Application on ships and maritime systems

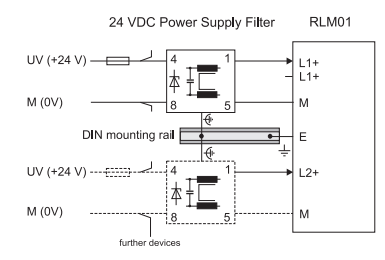

RLM01 is certified for applications on ships and maritime systems by the Germanic Lloyd (GL). To meet the increased requirements regarding EMC and overvoltage, RLM01 must have one or two "24 VDC power supply filters (surge)" depending on the supply (single / redundant). The supply of several RLM01 behind one filter is not admissible. The max. length of the lines between filter and RLM01 must not exceed 1 m. Possibly needed fuse elements have to be arranged before the filter. The electrical connection to ground potential is effected via the module attachment as with RLM01. The following example shows the interconnection in case of a redundant supply of RLM01. For a single supply of RLM01, the L2+ terminal has to be bridged with the second L1+ terminal.

Section 4 Monitoring

The LEDs assigned to lines A, B and M on the front panel are used to indicate bus activity (Act) and possible errors (Err) on the PROFIBUS lines. The monitoring logic in RLM 01 assumes that lines A & B are used for communication during operation. If it is subsequently possible to receive data over only one of the two lines, the non-available line is reported as faulty. If the redundant (second) line also fails, the same state results for the monitoring logic as for a redundant PROFIBUS link A AND B that is not in operation at all. Since the logic has no criterion for making a distinction, no error message is generated by RLM 01. The alarm contact remains closed and the two Act and Err LEDs are unlit. But the condition just described does not go undetected. In this case the PROFIBUS master generates the error message, since it cannot access the slaves either via line A or line B. An Err LED flashing at an undefined pulse/pause ratio indicates that the line in question has failed AND that there is only sporadic data traffic on the redundant line. The monitoring logic can only indicate operating and error states correctly if the baud rate is set correctly. RLM 01 also tests whether the supply voltage is present at inputs L1+ and L2+. A single power supply with L1+ alone always requires a cable jumper from L1+ to L2+ (see Chapter 3). This prevents an unwanted error message

Section 5 Signalling

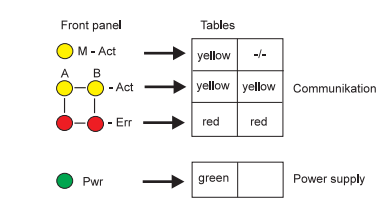

The monitoring logic in RLM 01 indicates operating and possible error states via LEDs on the front panel. In normal operation, all yellow Act LEDs (flashing or continuous) and the green Pwr LED are lit. The two red Err LEDs are unlit. Any signalling configuration other than this indicates a communication or power supply error

The text (yellow, red, green) in the two following tables means that the corresponding LED is lit, thus displaying an operating or error state