ABB Ability™ Symphony® Plus

HR Series Control and I/O Achieving total plant automation with a single control and I/O platform

ABB Ability™ Symphony® Plus is the new generation of ABB’s highly acclaimed Symphony family of distributed control systems – the world’s most widely used DCS in power generation and water management applications. In all, there are more than 7,000 Symphony DCS installations in operation all over the world, more than 5,000 of which are in power and water applications.

No other automation platform has such a long field record and large global installed base as ABB’s Symphony Plus family. For more than 35 years, the system has progressed through several evolutionary steps. From Network 90 in 1980, through INFI 90TM, INFI 90TM Open, and Symphony, to Symphony Plus, the system progression has followed ABB’s long-held policy of ‘Evolution without obsolescence,’ ensuring that each new generation enhances its predecessor all the while maintaining full compatibility with them.

Symphony Plus includes a comprehensive suite of standards-based control and I/O hardware and software that meets your requirements for total plant control. The suite's HR Series (Harmony Rack) meets the past, present and future needs of its users by protecting their previous control investments while delivering higher performance, reliability, and capacity. HR Series control-based systems feature scalable,

high-performance controllers, a comprehensive set of I/O options, fast, secure and redundant communications, an efficient easy-to-use engineering tool, and a state-of-the-art HMI workplace. Newest additions to the HR Series portfolio include an environmentally hardened DIN-rail mounted native remote I/O option and integration of intelligent electrical and field devices via PROFIBUS, HART and Modbus TCP communication protocols.

high-performance controllers, a comprehensive set of I/O options, fast, secure and redundant communications, an efficient easy-to-use engineering tool, and a state-of-the-art HMI workplace. Newest additions to the HR Series portfolio include an environmentally hardened DIN-rail mounted native remote I/O option and integration of intelligent electrical and field devices via PROFIBUS, HART and Modbus TCP communication protoco

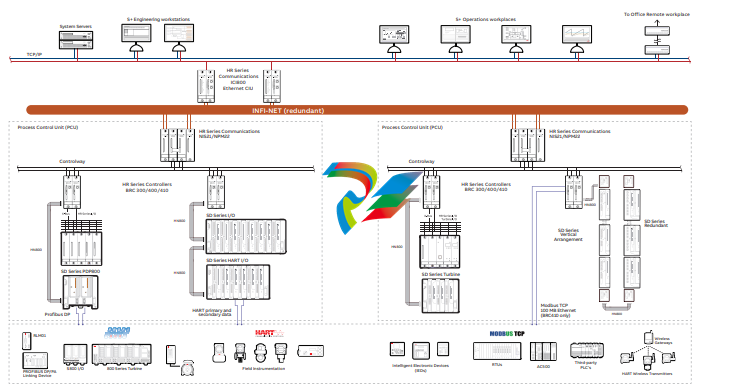

Overview Symphony Plus HR Series provides a scalable solution that spans and integrates loop, unit, area, plant and interplant controls. Its system communication architecture is based on a high-speed, high-throughput and highsecurity redundant INFI-Net control network. The scalable network supports any combination and quantity of control, engineering, operation and application interface nodes. Each node on the control network operates independently of other nodes. Acting as its own communication manager, the system requires no traffic directors. INFI-Net to INFI-Net communication modules support multinetwork system topologies that provide a system capacity of more than 62,000 nodes.

High system reliability and availability are key characteristics of this mission-critical control network. Reliability is bolstered by redundant hardware and communication paths. Extensive use of error checking and message acknowledgment assures accurate communication of critical process data. Patented exception reporting technology optimizes the use of control network bandwidth. The store and forward ring topology of INFI-Net, along with multi-master and multi-cast messaging features result in INFI-Net having an effective bandwidth that exceeds 300 Mbaud. INFI-Net communications are also highly deterministic.

HR Series process control unit (PCUs) communication products including the NIS21/ NPM22 modules provide significant increases to performance and capacity compared to previous generations. Additionally, new HR Series INFI-Net to Computer Interface (ICI), INFINet to INFI-Net Local and Remote Bridge modules, and INFINet to PN800 (INFI-Net over Ethernet) Bridge modules are available.

The Harmony OPC server provides OPC connectivity between devices on the INFI-Net control network and OPC client applications. In non-redundant and redundant configurations, it can be used in conjunction with ABB products such as DataLink and popular non-ABB products such as OSIsoft PI System and Aspen InfoPlus.21.

HR Series ICI800 Ethernet CIU provides Ethernetbased communication between INFI-Net and the system’s engineering tools, HMI and the Harmony OPC server for connection to thirdparty applications. As per NERC CIP-007-2 R5, SSL certifications authenticate its connections with interface applications, further safeguarding the integrity and privacy of the ICI800 communication path.

HR Series Achieving greater levels of performance

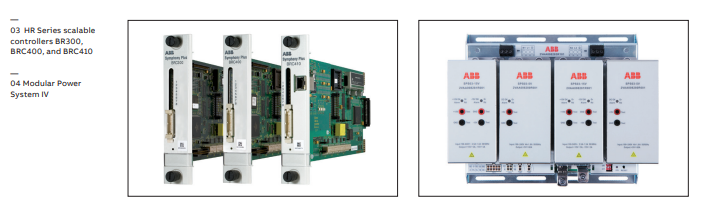

Powerful, scalable control platform HR Series controllers are the latest in a long line of field-proven multi-function rack process controllers, and include the BRC300, BRC400, and the BRC410 bridge controllers (figure 3). This scalable family of controllers, based on a 160 MHz, 32-bit Freescale Coldfire processor, can be adapted to a broad spectrum of applications and process requirements. HR Series controllers feature an extensive library of more than 150 predefined control algorithms or function codes. These functions provide the power to easily design complex control strategies to fit any control application, including continuous, sequential, batch and advanced control. In addition to standard function blocks, HR Series controllers support C programming and batch functions.

HR Series controller features include:

• Enhanced controller reliability

• More than 10x performance of previous generation controllers

• Simultaneous support for all HR Series I/O, SD Series I/O and S800 I/O subsystems

• Intelligent device integration via HART I/O and PROFIBUS DP V0, V1, V2

• Downloadable firmware

• BRC400 / BRC410 specific enhancements: – Extended user configuration memory (2 MB NVRAM) – Support for 30,000 function blocks – Flexible online configuration capability – Modbus TCP device integration via 100 MB Ethernet port (BRC410 only)

High reliability and availability With redundant controller, communication, I/O and power options such as the recently released MPS IV (Modular Power System), HR Series controller subsystems provide the highest level of availability. Compliance with international standards assures the highest level of reliability and quality needed to meet the most rigorous global specifications and requirements. Backward compatibility through ABB’s ‘Evolution without obsolescence’ life cycle program ensures protection of installed investments while providing the most cost-effective and seamless way of introducing new functions and technology into a running plant. Together, the HR Series provides users with fast, accurate, uninterrupted control of their process, resulting in greater production efficiency, increased availability, and lower maintenance costs.

Soft controller reduces commissioning times For new plant, upgrade, or expansion projects, HR Series soft controllers can dramatically reduce commissioning and start-up time and costs by permitting thorough testing and pre-tuning of control loops prior to its implementation in the field. The HR Series soft controller uses the same control logic (ie, function block configuration) as the physical HR Series controllers. Coupled with virtual communication devices, the entire HR Series control-based system can be implemented within one or more PCs which allow for testing results made in the virtual environment to be directly transferable to the operating system environment.