Foxboro FBM202 Thermocouple/mV Input Module

FBM202 Thermocouple/mV Input Module

he FBM202 Thermocouple/mV Input contains eight thermocouple input channels, and one isolated RTD

reference junction compensation channel.

OVERVIEW

The FBM202 Thermocouple/mV Input contains eight

thermocouple input channels, and one isolated RTD

reference junction compensation channel (for terminal

temperature sensing). Each thermocouple/mV

channel accepts standard thermocouples for various

temperature ranges, and each provides

thermocouple burnout detection (up-scale). The

inputs are galvanically isolated from other channels

and ground.

The module performs the signal conversion required

to interface the electrical input signals from the field

sensors to the optionally redundant Fieldbus. It

executes an Analog Input application program, which

provides integration time and Rate of Change Limits

configurable options

When connected to the appropriate TAs, the

FBM202 module provides functionality formerly

provided by the 100 Series FBM I/O subsystem. TAs

are available which support the functionality of the

100 Series FBM02.

FEATURES

Key features of the FBM202 are:

Eight channels for input of thermocouple signals

One isolated RTD reference junction

compensation channel (for terminal temperature

sensing)

Each input channel is galvanically isolated

Rugged design suitable for enclosure in Class G3

(harsh) environments

Execution of an analog input application program

that provides conversion time and configurable

options for Rate of Change Limits

High accuracy achieved by sigma-delta data

conversions for each channel

Termination Assemblies (TAs) for locally or

remotely connecting field wiring to the FBM202

HIGH ACCURACY

For high accuracy, the module incorporates Sigma

Delta data conversion on a per-channel basis, which

can provide new analog input readings every 25 ms,

and a configurable integration period to remove any

process noise and power line frequencies.

Each time period, the FBM converts each analog

input to a digital value, averages these values over

the time period and provides the averaged value to

the controller.

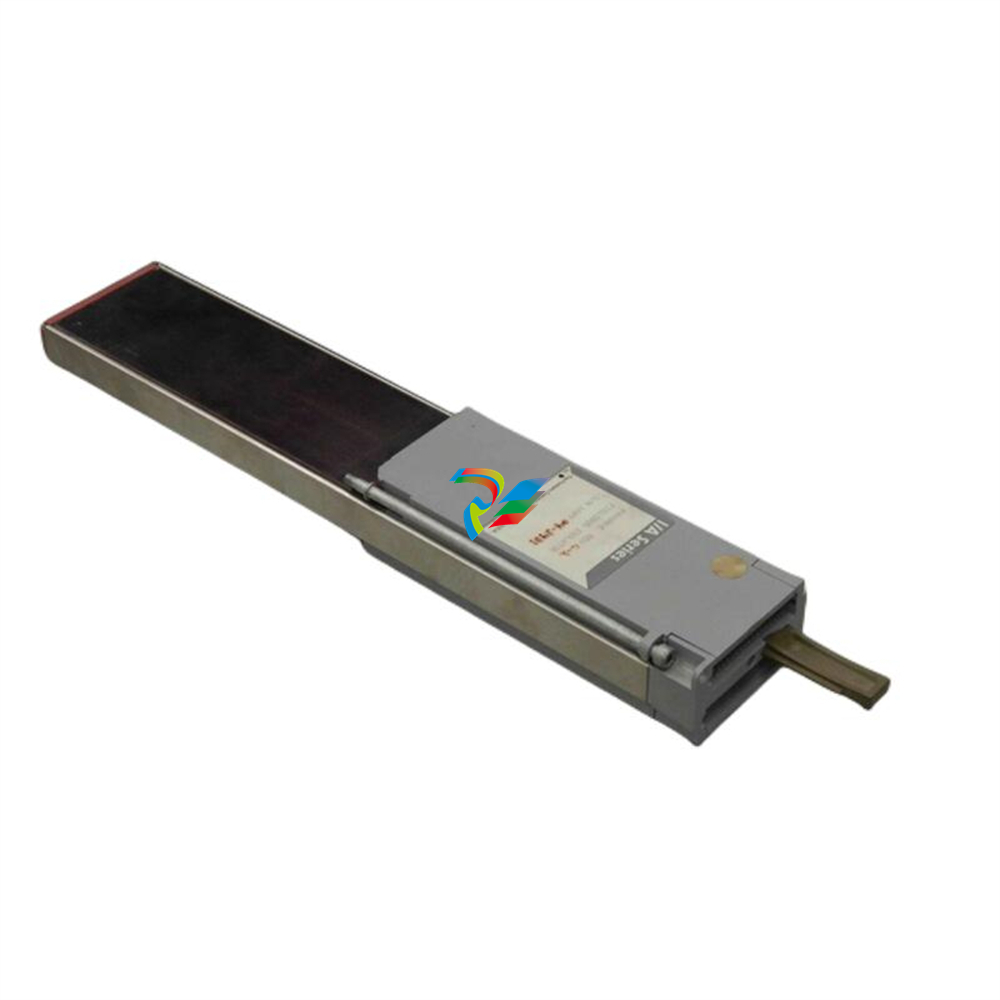

STANDARD DESIGN

FBM202 has a rugged extruded aluminum exterior

for physical protection of the circuits. Enclosures

specially designed for mounting the FBMs provide

various levels of environmental protection, up to

harsh environments, per ISA Standard S71.04.

VISUAL INDICATORS

Red and green light-emitting diodes (LEDs)

incorporated into the front of the module provide

visual status indications of the FBM operational

status.

EASY REMOVAL/REPLACEMENT

The module can be removed/replaced without

removing field device termination cabling, power, or

communications cabling.

FIELDBUS COMMUNICATION

A Fieldbus Communications Module or a Control

Processor interfaces to the redundant 2 Mbps

module Fieldbus used by the FBMs. The FBM

accepts communication from either path (A or B) of

the 2 Mbps Fieldbus — should one path fail or be

switched at the system level, the module continues

communication over the active path.

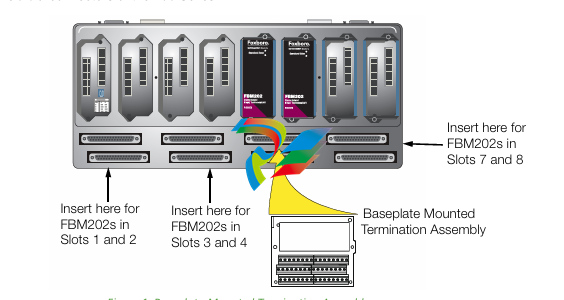

MODULAR BASEPLATE MOUNTING

The module mounts on a DIN rail mounted

baseplate, which accommodates up to four or eight

Fieldbus Modules. The Modular baseplate is either

DIN rail mounted or rack mounted, and includes

signal connectors for redundant Fieldbus, redundant

independent dc power, and termination cables.

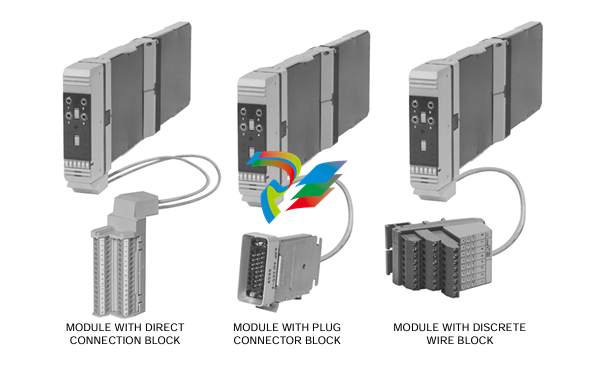

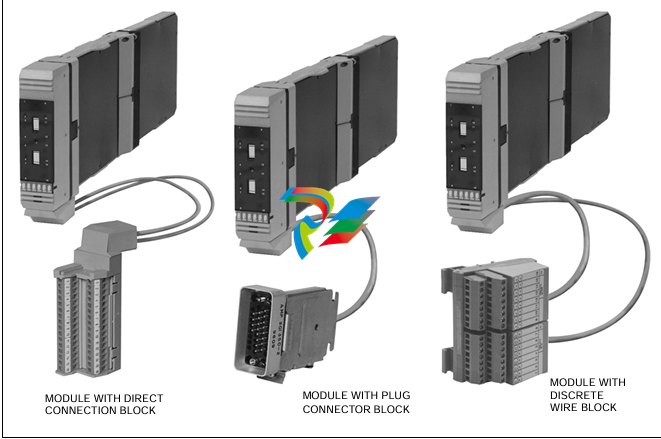

TERMINATION ASSEMBLIES

Field I/O signals connect to the FBM subsystem via

DIN rail mounted TA, or

Baseplate-mounted TA.

The TAs used with the FBM202 are described in

“FUNCTIONAL SPECIFICATIONS – TERMINATION

ASSEMBLIES” on page 8.

FUNCTIONAL SPECIFICATIONS

Input Channels

Eight isolated and independent thermocouple/mV

input channels. One isolated reference junction

temperature compensation channel.

Input Range–10.5 to +69.5 mV dc (–10.5 to +69.5 mV dc equals

0 to 64000 raw counts. Input of 71.419 mV equals

65535 raw counts (full range of module))

Reference Junction

Reference junction temperature compensation is

provided by a 4-wire 100 ohm platinum RTD

(IEC 751. Class B) at the termination assembly.

Accuracy

MILLIVOLT INPUT

±0.03% of span (±24 µV) at 25°C

RTD CHANNEL

±0.03% of span

RTD REFERENCE JUNCTION CONFORMITY

±0.25°C

THERMOCOUPLE CONFORMITY

±0.25°C

ACCURACY TEMPERATURE COEFFICIENT

±50 ppm/°C

Input Signal A/D Conversion

Each channel performs A/D signal conversion using

an independent Sigma-Delta converter.

Typical Thermocouple Types

B, E, J, K, N, R, S, T and other millivolt signals

Thermocouple Burnout Detection

Full upscale value

Input Channel Isolation

Each channel is galvanically isolated from all other

channels and earth (ground). The module withstands,

without damage, a potential of 600 V ac applied for

one minute between any channel and ground, or

between a given channel and any other channel.

CAUTION

This does not imply that these channels are

intended for permanent connection to

hazardous voltage circuits. Connection of

thes

FUNCTIONAL SPECIFICATIONS (CONTINUED)

Regulatory Compliance

ELECTROMAGNETIC COMPATIBILITY (EMC)

Eur

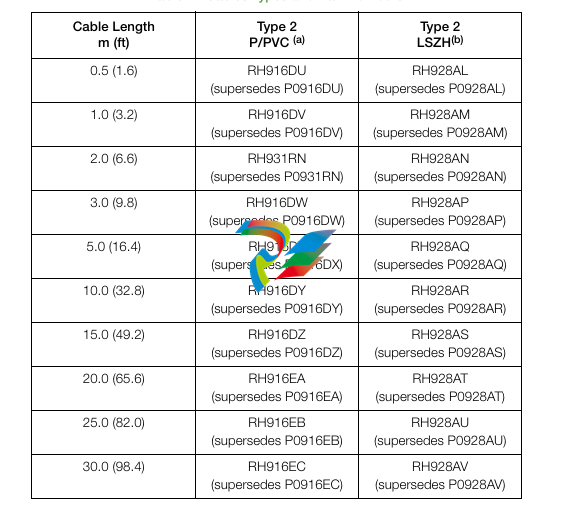

PHYSICAL SPECIFICATION (CONTINUED)

Termination Cables

CABLE LENGTHS

Up to 30 m (98 ft)

CABLE MATERIALS

Polyurethane or Low Smoke Zero Halogen

(LSZH)

TERMINATION CABLE TYPE

Type 2 - Refer to Table 2.

CABLE CONNECTION

FBM Baseplate End

37-pin D-subminiature

Termination Assembly End

25-pin D-subminiature

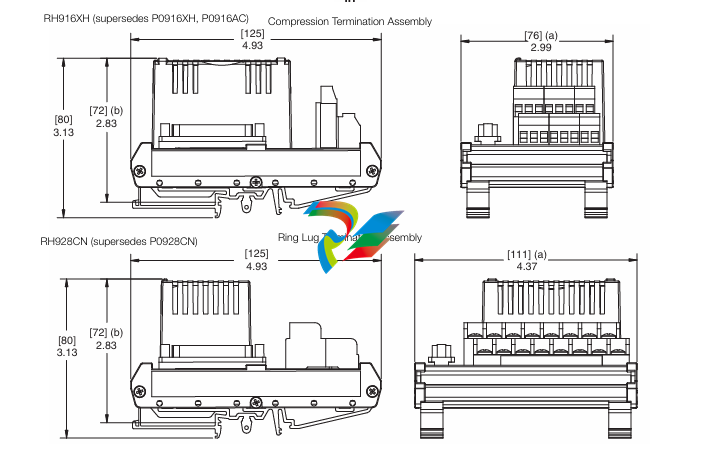

Construction - Termination Assembly

MATERIAL

DIN Rail Mounted TAs

Polyamide (PA), compression and ring lug

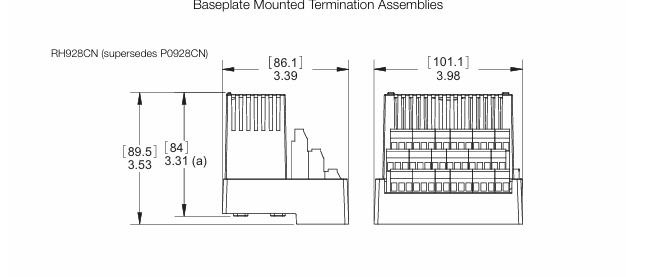

Baseplate-Mounted TAs

Polycarbonate/Acrylonitrile Butadiene

Styrene (PC/ABS), compression

TERMINATION ASSEMBLIES AND CABLES

Field I/O signals connect to the FBM subsystem via

DIN rail mounted or baseplate mounted termination

assemblies (TAs). Both these types of TAs are

electrically passive. The TAs for the FBM202 are

available in the following forms:

Compression screw type (DIN rail mounted) using

Polyamide (PA) material

Compression screw type (baseplate mounted)

using Polycarbonate/Acrylonitrile Butadiene

Styrene (PC/ABS)

Ring lug type (DIN rail mounted) using Polyamide

(PA) material

Each DIN rail mounted TA and its associated

termination cable provides a feedthrough connection

between eight 2-wire thermocouple/mV analog input

signals and an FBM202 Thermocouple/mV Input

Module. Each baseplate mounted TA provides a

Field Termination Connections

DIN RAIL TA COMPRESSION-TYPE ACCEPTED

WIRING SIZES

Solid/Stranded/AWG

0.2 to 4 mm2/0.2 to 2.5 mm2/24 to 12 AWG

Stranded with Ferrules

0.2 to 2.5 mm2 with or without plastic collar

BASEPLATE MOUNTED TA COMPRESSION -

ACCEPTED WIRING SIZES

Solid/Stranded/AWG

0.2 to 1.5 mm2/0.2 to 1.5 mm2/24 to 16

AWG

Stranded with Ferrules

0.25 to 0.75 mm2 with plastic collar

0.25 to 1.5mm2 without plastic collar

RING-LUG - ACCEPTED WIRING SIZES

#6 size connectors (0.375 in (9.5 mm))

0.5 to 4 mm2/22 AWG to 12 AWG

feedthrough connection between sixteen 2-wire

thermocouple/mV analog input signals and two

FBM202 Thermocouple/mV Input Modules.

Reference junction temperature compensation is

provided by an isolated resistance temperature

detector (RTD) that is integral to the termination

assembly. The baseplate mounted TA contains an

RTD for each FBM202.

See “FUNCTIONAL SPECIFICATIONS –

TERMINATION ASSEMBLIES” on page 8 for a list of

TAs used with the FBM202 module.

A removable termination cable connects the DIN rail

mounted TA to the FBM via a field connector on the

baseplate in which the FBM is installed. Termination

cables are available in the following materials:

Polyurethane

Low Smoke Zero Halogen (LSZH).

Termination cables are available in a variety of

lengths, up to 30 meters (98 feet), allowing the

termination assembly to be mounted in either the

enclosure or in an adjacent enclosure. See Table 2

for a list of termination cables used with the TAs for

the FBM202 module.

Upgrade Subsystem

When an FBM202 is used to replace the 100 Series

FBM02. it may use any of the appropriate termination

assemblies listed above for the FBM02’s field I/O

wiring. Alternatively, the FBM202 can accept this field

wiring through a Termination Assembly Adapter (TAA)

instead of a termination assembly. This is discussed

in Termination Assembly Adapter Modules for

100 Series Upgrade (PSS 31H-2W4)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)