GE350 Feeder Protection System

GENERAL SAFETY PRECAUTIONS - 350

• Failure to observe and follow the instructions provided in the equipment manual(s)

could cause irreversible damage to the equipment and could lead to property

damage, personal injury and/or death.

• Before attempting to use the equipment, it is important that all danger and caution

indicators are reviewed.

• If the equipment is used in a manner not specified by the manufacturer or

functions abnormally, proceed with caution. Otherwise, the protection provided by

the equipment may be impaired and can result in Impaired operation and injury.

• Caution: Hazardous voltages can cause shock, burns or death.

• Installation/service personnel must be familiar with general device test practices,

electrical awareness and safety precautions must be followed.

• Before performing visual inspections, tests, or periodic maintenance on this device

or associated circuits, isolate or disconnect all hazardous live circuits and sources

of electric power.

• Failure to shut equipment off prior to removing the power connections could

expose you to dangerous voltages causing injury or death.

• All recommended equipment that should be grounded and must have a reliable

and un-compromised grounding path for safety purposes, protection against

electromagnetic interference and proper device operation.

• Equipment grounds should be bonded together and connected to the facility’s

main ground system for primary power.

• Keep all ground leads as short as possible.

• At all times, equipment ground terminal must be grounded during device

operation and service.

• In addition to the safety precautions mentioned all electrical connections made

must respect the applicable local jurisdiction electrical code.

• Before working on CTs, they must be short-circuited.

• LED transmitters are classified as IEC 60825-1 Accessible Emission Limit (AEL) Class

1M. Class 1M devices are considered safe to the unaided eye. Do not view directly

with optical instruments.

• This product uses optical electronic devices (line or point sensors) to sense arc

flash fault conditions. It is recommended to follow proper housekeeping measures

and establish a regularly scheduled preventive maintenance routine to ensure

proper device operation.

• This product itself is not Personal Protective Equipment (PPE). However, it can be

used in the computation of site-specific arc flash analysis when the arc flash

option is ordered. If a new appropriate Hazard Reduction Category code for the

installation is determined, the user should follow the cautions mentioned in the arc

flash installation section.

• This guide is intended to provide protective relay application guidance to mitigate

arc flash incident energy. This guide does not endorse energized work. This guide

does not claim that protective relaying can totally protect personnel from the

dangers of an arc flash. The only way to completely prevent injury from arc flash

events is to de-energize the equipment and properly follow safe lockout/tagout

procedures to ensure the equipment remains de-energized.

Safety words and definitions

The following symbols used in this document indicate the following conditions

Note Indicates a hazardous situation which, if not avoided, will result in death or serious

injury.

Note Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Note Indicates a hazardous situation which, if not avoided, could result in minor or

moderate injury.

Note Indicates practices not related to personal injury

Overview

The 350 is a microprocessor-based relay for primary and backup over-current protection

of medium and low voltage distribution feeders. The relay is also suitable for providing

over-current and backup protection for small and medium size motors, transformers,

generators, and distribution bus-bars. The small footprint and the withdrawable option

make the 350 relay ideal for panel mounting on either new or retrofit installations. The

combination of proven hardware, a variety of protection and control features, and

communications, makes the relay ideal for total feeder protection and control. Equipped

with serial (RS485), USB, and Ethernet ports with the possibility of adding redundancy

(IEC62439, PRP and HSR), and a wide selection of protocols such as Modbus, DNP3.0, IEC

60870-5-103, 60870-5-104, IEC61850 GOOSE, OPC-UA, the 350 relay is the best-in-class

for MCCs and PCCs, SCADA and inter-relay communications. The 350 relay provides

excellent transparency with respect to power system conditions and events, through its

four-line 20-character display, as well as the EnerVista 3 Series Setup program.

Conveniently located LEDs provide indication of relay operation, alarm, and pickup, as well

as breaker, and relay status.

The 350 relay provides the following key benefits:

• Withdrawable small footprint – saves on rewiring and space. (non-draw out version is

also available)

• Multiple protection groups with the added flexibility of switching through a wide

selection of overcurrent protection and control features.

• Fast setup (Quick Setup) menu for power-system setup and a simple overcurrent

protection configuration.

• Large four-line LCD display, LEDs, and an easy-to-navigate keypad.

• Multiple communication protocols for simultaneous access when integrated into

monitoring and control systems.

Description of the 350 Feeder Protection System

CPU

Relay functions are controlled by two processors: a Freescale MPC5554 32-bit

microprocessor measures all analog signals and digital inputs and controls all output

relays; a Freescale MPC520B 32-bit microprocessor controls all the Ethernet

communication protocols.

Analog Input and Waveform Capture

Magnetic transformers are used to scale-down the incoming analog signals from the

source instrument transformers. The analog signals are then passed through a 960 Hz low

pass anti-aliasing filter. All signals are then simultaneously captured by sample and hold

buffers to ensure there are no phase shifts. The signals are converted to digital values by a

12-bit A/D converter before finally being passed on to the CPU for analysis.

Both current and voltage are sampled thirty-two times per power frequency cycle. These

‘raw’ samples are scaled in software, then placed into the waveform capture buffer, thus

emulating a fault recorder. The waveforms can be retrieved from the relay via the EnerVista

3 Series Setup software for display and diagnostics.

Frequency

Frequency measurement is accomplished by measuring the time between zero crossings

of the Bus VT phase A voltage. The signals are passed through a low pass filter to prevent

false zero crossings. Sampling is synchronized to the Va-x voltage zero crossing which

results in better co-ordination for multiple 350 relays on the same bus.

Phasors, Transients, and Harmonics

Current waveforms are processed four times every cycle with a DC Offset Filter and a

Discrete Fourier Transform (DFT). The resulting phasors have fault current transients and

all harmonics removed. This results in an overcurrent relay that is extremely secure and

reliable; one that will not overreach.

Processing of AC Current Inputs

The DC Offset Filter is an infinite impulse response (IIR) digital filter, which removes the DC

component from the asymmetrical current present at the moment a fault occurs. This is

done for all current signals used for overcurrent protection; voltage signals bypass the DC

Offset Filter. This filter ensures no overreach of the overcurrent protection.

The Discrete Fourier Transform (DFT) uses exactly one sample cycle to calculate a phasor

quantity which represents the signal at the fundamental frequency; all harmonic

components are removed. All subsequent calculations (e.g. RMS, power, etc.) are based

upon the current and voltage phasors, such that the resulting values have no harmonic

components.

Protection Elements

Protection elements are processed up to four times every cycle to determine if a pickup

has occurred or a timer has expired. The protection elements use RMS current/voltage,

based on the magnitude of the phasor. Hence, protection is impervious to both harmonics

and DC transients.

NOTE

NOTE: Arc Flash protection elements are processed up to 8 times every cycle.

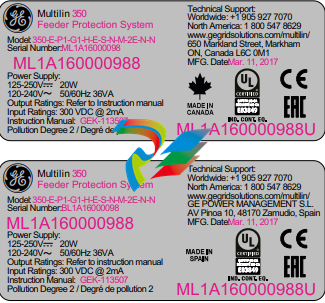

Product identification

The product identification label is located on the side panel of the 350 . This label indicates

the product model, serial number, and date of manufacture.

Figure 2-3: 350 Product labels

The pink color text (i.e. Model, Serial Number, Instruction Manual, MFG. Date) is for

reference only. The text can vary.

Mounting

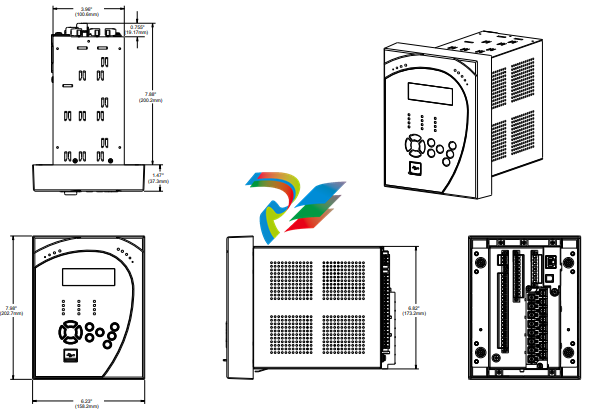

Standard panel mount The standard panel mount and cutout dimensions are illustrated below.

CAUTION: To avoid the potential for personal injury due to fire hazards, ensure the unit is

mounted in a safe location and/or within an appropriate enclosure.

1. Mount the collar of required depth (1.375” or 3”) to the unit (captive or non-drawout)

using 4 screws (see above).

2. Mount the combination of unit and collar to the panel using 4 screws as shown above.

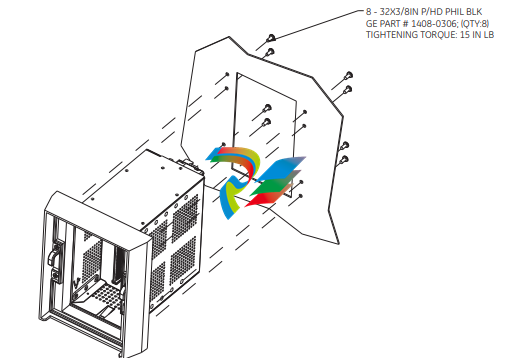

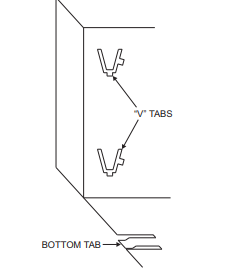

Figure 2-7: Mounting tabs (optional)

1. From the front of the panel, slide the empty case into the cutout until the bottom tab

clicks into place (see above).

2. From the rear of the panel screw the case into the panel at the 8 screw positions

shown above.

3. If added security is required, bend the retaining "V"tabs outward, to about 90°. These

tabs are located on the sides of the case and appear as shown above.

The relay can now be inserted and can be panel wired.

P20 Cover (optional)

The IP20 cover minimizes potential dangers to users by preventing finger contact with

electrical connections at the back of the 3 Series drawout units.

Attaching the cover

The steps for attaching the IP20 cover (optional) to the drawout unit are as follows:

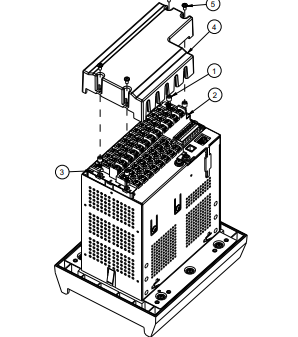

Figure 2-13: IP20 Cover mounting - Drawout unit only

1. Place 4 custom standoffs (item#1) using the suggested tightening torque of 8lb-in in

the following order:

A. Remove the 2 mounting screws near letters A and C, of label ABC (item#2), and

mount 2 standoffs.

B. Remove the 2 mounting screws near the letters B and E, of label ABCDE (item#3),

and mount 2 standoffs.

2. Place the IP20 cover (item#4) and secure it with 4 screws (item#5) using the suggested

tightening torque of 8lb-in.

NOTE

NOTE: Make sure the device terminals are wired before placing the cover. Use the 5 slots located

on each side of the cover to guide the wires outside of the cover.

Retrofit kit for IP20

Before attaching the cover, remove the old labels from the device (see item#2 and item#3)

and replace them with the new labels from the retrofit kit. Attach the cover as described in

the previous section.

Arc flash sensors

Arc flash sensors house the fiber optics that are used to detect the arc flash. Mounting

details depend on the sensor type (point or loop).

For detailed installation, testing and maintenance guidance for Arc Flash sensors, see GET20057 3 Series Arc Flash Application Note.

If the relay is used in the computation for reducing the Hazard Reduction Category

code, operands for sensor failures must be assigned to an auxiliary output relay which

must be connected into the control logic of the breaker equipment to ensure safe

operations when the output relay is asserted. In the event of this assertion, the Hazard

Reduction Category code cannot be maintained unless backup protection is continuing

to maintain it.

CAUTION: This product uses optical electronic devices (line or point sensors) to sense arc flash

fault conditions. It is recommended to follow proper housekeeping measures &

establish a regularly scheduled preventive maintenance routine to ensure proper

device operation. For maintenance recommendations, see GET-20057 3 Series Arc

Flash Application Note

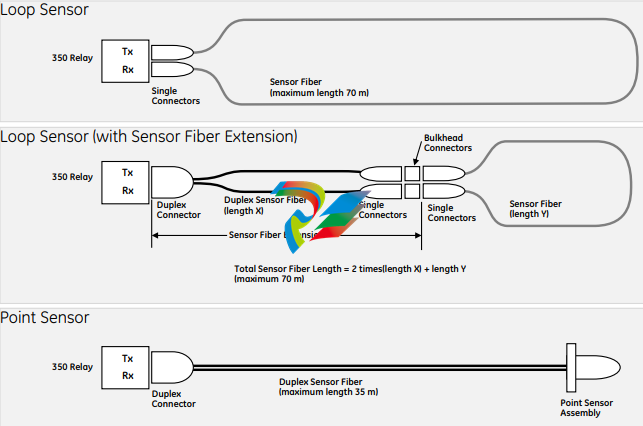

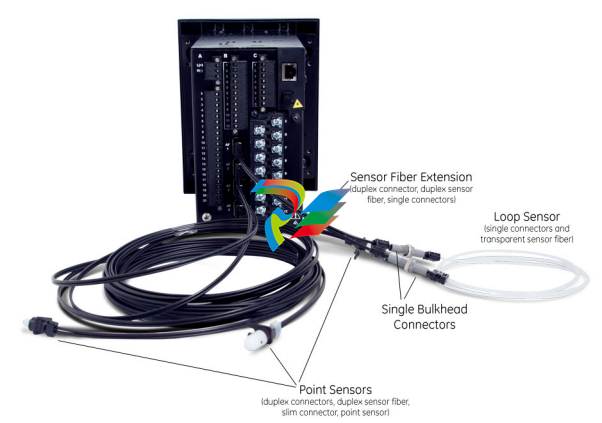

Arc flash sensors are available in two different configurations, point and loop. Loop sensors

can be used with a black-coated sensor fiber extension to connect the ends of the loop

sensor to the 350 relay through panels up to 51 mm (2 inches) thick.

Arc Flash sensor fiber is pressure sensitive and must be handled carefully to avoid

damage. Read the following guidelines fully before proceeding.

Care must be taken when handling the Arc Flash sensor fiber, which can be damaged if

twisted, bent, or clamped tightly during installation.

• Do not bend sensor fiber sharply, or with a radius of less than 35 mm (1.3 inches).

Sharp bends can damage the fiber. Do not pull or tug loops of sensor fiber, as sharp

bends may result.

• Do not clamp sensor fiber tightly during installation. Sensor fiber should be held in

place loosely for the best long-term performance. Avoid over-tightening ties which

may deform or break the sensor fiber.

• Do not pull or tug sensor fiber with force, as this may cause internal damage or

separate the fiber from the cable connector.

• Do not twist the sensor fiber, as twisting can damage the fiber resulting in

substandard performance.

• Do not attach sensor fiber directly to the bus or other live conductors.

• Avoid surface temperatures above 70 °C or 158 °F to prolong the life of the fiber.

• Secure all sensor fibers (loosely but securely) away from any moving parts.

The point sensor fiber includes a duplex connector to connect to the back of the 350 relay

on one end, and a compressed slim connector that connects to the sensor itself on the

other end.

Before installing the AF sensor units, ensure that all other drilling and installation is

complete to minimize possible damage to the sensitive unit and connected sensor fiber

cable. Choose a location for the sensor clear of any obstructions that could shield the

sensor from arc flash light.

FASTPATH: Review the sensor fiber handling guidelines above.

Sensor fiber should be held in place loosely for the best long-term performance. Avoid

over-tightening ties which may deform or break the sensor fiber.

General installation:

1. Choose a location for the point sensor.

Arc flash point sensors should be installed clear of any obstructions that could shield

the sensor from arc flash light, and less than 2m (6ft 6") from any potential arc flash

source.

The sensor head should be pointed towards the most likely source of arc flash.

For further guidance selecting point sensor locations, see GET-20057 3 Series Arc

Flash Application Note.

2. Remove the slim connector from the point sensor assembly.

3. Carefully route the duplex sensor fiber from the point sensor location to the back of

the relay unit, minimizing loops and curves for the strongest possible signal. Ensure all

sensor fiber handling precautions are followed.

The slim connecter fits through holes with a diameter of 11 mm or greater, and can be

threaded through holes drilled in any panels between the relay and arc flash detection

location.

NOTE

NOTE: Install protective grommets when routing sensor fiber through metal walls.

4. Mount the point sensor using either a cable tie mount or through-hole mount, as

detailed below.

5. Reconnect the slim connector to the point sensor.

Arc flash point sensors can be installed in one of two ways, using a cable tie mount or a

through-hole mount.

Cable tie mount:

• Requires a 2.5-mm-wide cable tie.

• Mount the sensor on a stick or similar using the cable tie, as shown in the following

figure.

Through-hole mount

• Requires a standard or self-tapping M3 screw, and optionally an M3 washer.

• Mount the sensor through a 10 mm hole made in the surface of any mechanical

structure inside the switchgear or on the surface of one side of the switchgear itself,

as shown in the following figure.

Make sure there is no dirt or dust inside the point sensor or on the surface because it

reduces the capturing efficiency of the device, increases its transmission loss, or both. If

the point sensor is covered with dust, clean it by blowing or wiping the dust off the point

sensor.

FASTPATH: The material of the point sensor is not affected by water-based cleaning agents, dish

soap, or organic solvents with an alcohol (ethanol) base. Do not use solvents or solvent

mixtures that contain acids because they can attack or dissolve the optical plastic

material.

Before installing the AF sensor units, ensure that all other drilling and installation is

complete to minimize possible damage to the sensitive unit and connected sensor fiber

cable.

FASTPATH: Review the sensor fiber handling guidelines above.

Sensor fiber should be held in place loosely for the best long-term performance. Avoid

over-tightening ties which may deform or break the sensor fiber.

FASTPATH: The loop sensor fiber can be connected directly to the 350 relay without a sensor fiber

extension, however, care must be taken to ensure correct alignment of the loop sensor

single connectors into the 350 light sensor input.

Installing the loop sensor fiber without an extension:

1. Plan the path of the loop sensor fiber, looping through the chamber or chambers

requiring arc flash detection. See GET-20057 3 Series Arc Flash Application Note for

detailed examples of loop sensor installation.

2. Ensure that both ends of the loop remain close together and can reach the 350 relay

light sensor inputs.

3. Install the loop sensor carefully, following all sensor fiber handling guidelines.

4. Plug the single connectors into the back of the 350 relay, ensuring correct alignment

as shown

Installing the loop sensor fiber with a sensor fiber extension:

1. Plan the path of the loop sensor fiber, looping through the chamber or chambers

requiring arc flash detection. See GET-20057 3 Series Arc Flash Application Note for

detailed examples of loop sensor installation.

2. Ensure that both ends of the loop remain close enough together to be reached by the

sensor fiber extension. If needed, gently pull apart the duplex sensor fiber extension

from the end with two single connectors, being careful not to bend the fiber with a

radius of less than 35 mm (1.3 inches).

3. Ensure that the sensor fiber extension is long enough to reach the 350 relay from the

bulkhead connector location.

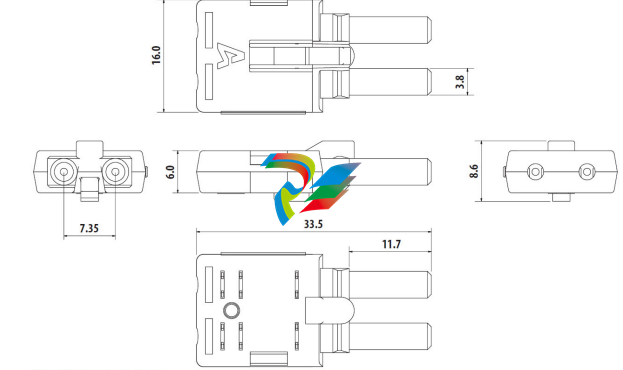

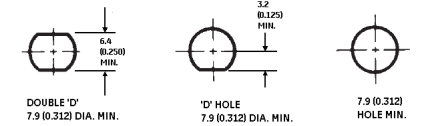

4. Mount the bulkhead connector on the side of the chamber, following the drill hole

dimensions provided. Note that the single bulkhead connector uses washers 11.0 mm

(0.420 in) wide, so the drill holes must be spaced accordingly if the loop sensor path

begins and ends in the same place.

Figure 2-26: Bulkhead connector cutout

5. Install the loop sensor carefully, following all sensor fiber handling guidelines.

6. Plug the ends of the loop sensor into the bulkhead connectors.

7. Plug the single connectors on the sensor fiber extension into the other sides of the

bulkhead connectors, and the duplex connector into the back of the 350 relay

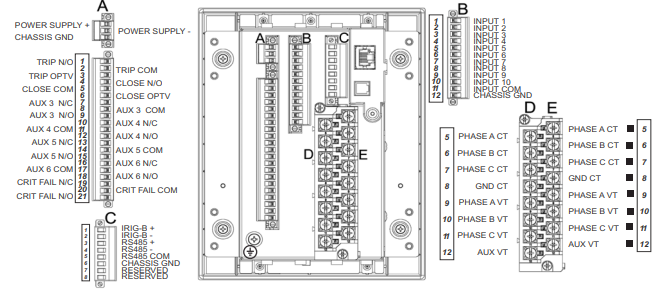

Wire range

Use the following guidelines when selecting wires or lugs to connect to terminal blocks

A,B,C,D,E (Drawout case design), and terminal blocks D,E (Non-drawout case design):

• 12 AWG to 22 AWG (3.3 mm2 to 0.3 mm2): Single wire termination with/without

9.53 mm (0.375”) maximum diameter ring terminals (#8).

• 14 AWG to 22 AWG (2.1 mm2 to 0.3 mm2): Multiple wire termination with matching

wire sizes and stranding. Two wires maximum per circuit.

• 14 AWG to 22 AWG (2.1 mm2 to 0.3 mm2): Multiple wire termination with 9.53 mm

(0.375”) maximum diameter ring terminals (#8). Two ring terminals maximum per

circuit.

• Suggested wiring screw tightening torque, tighten to 12 in-lb (1.35 N-m).

• Minimum suggested temperature rating for the conductors is 75C.

Use the following guidelines when selecting wires to connect to terminal strip F (Drawout

case design), and terminal strips A,B,C (Non-drawout case design):

• 12 AWG to 24 AWG (3.3 mm2 to 0.2 mm2)

• Suggested wiring screw tightening torque: 4.5 in-lbs (0.5 N-m)

• The uncovered communications cable shield connected to the common terminal

should not exceed 1” (2.5 cm) for proper EMC shielding of the communications cable.

Phase sequence and transformer polarity

For correct operation of the relay features, the user must follow the instrument

transformer polarities, shown in the Typical Wiring Diagram. Note the solid square

markings shown with all instrument transformer connections. When the connections

adhere to this drawing, the arrow shows the direction of power flow for positive watts and

the positive direction of lagging vars.The phase sequence is user programmable for either

ABC or ACB rotation.

Current inputs

The 350 relay has four (4) channels for AC current inputs, each with an isolating

transformer. There are no internal ground connections on the current inputs. Current

transformers with 1 to 6000 A primaries may be used.

CAUTION: Verify that the relay’s nominal input current of 1 A or 5 A matches the secondary rating

of the connected CTs. Unmatched CTs may result in equipment damage or inadequate

protection.

CAUTION: IMPORTANT: The phase and ground current inputs will correctly measure up to 20

times the current input’s nominal rating. Time overcurrent curves become horizontal

lines for currents above the 20 × CT rating. This becomes apparent if the pickup level is

set above the nominal CT rating.

CAUTION: Before working on CTs, they MUST be short circuited.

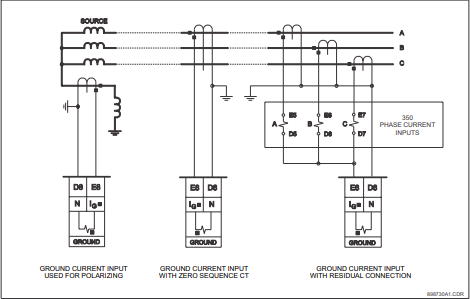

Ground and sensitive ground CT inputs

One dedicated ground input is referred to throughout this manual as the Ground Current

or Sensitive Ground Current input. Before making ground connections, consider that the

relay automatically calculates the neutral (residual) current from the sum of the three

phase current phasors. The following figures show three possible ground connections (or

three possible sensitive ground connections).

The ground input (Terminals D8 and E8) is used in conjunction with a Zero Sequence CT as

source, or in the neutral of wye-connected source CTs. The ground current input can be

used to polarize the neutral directional element. When using the residual connection set

the GROUND CT PRIMARY setpoint to a value equal to the PHASE CT PRIMARY setpoint.

In cases where the relay is equipped with sensitive ground CT (terminals D8 and E8) the

sensitive ground current input is intended for use either with a CT in a source neutral of a

high-impedance grounded system, or on ungrounded systems. On ungrounded systems it

is connected residually with the phase current inputs. In this case, the SENSTV GND CT

PRIMARY setpoint should be programmed to a value equal to the PHASE CT PRIMARY

setpoint. The sensitive ground current input can be connected to a Zero Sequence CT for

increased sensitivity and accuracy when physically possible in the system.

NOTE

NOTE: The Sensitive Ground input must only be used on systems where the maximum ground

current does not exceed current input specifications

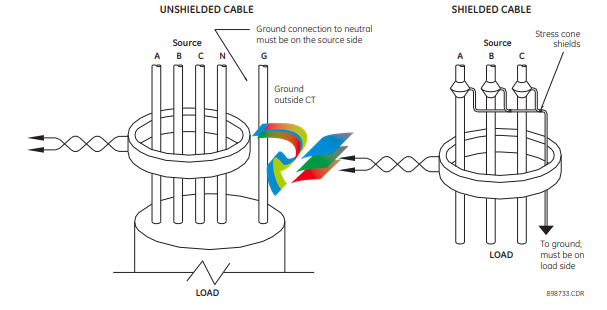

Zero sequence CT installation

The various CT connections and the exact placement of a Zero Sequence CT, for ground

fault current detection, are shown in the figure below. Twisted pair cabling on the Zero

Sequence CT is recommended.

Figure 2-35: Zero sequence core balance (CT) installation

Voltage inputs

The 350 relay has four channels for AC voltage inputs, each with an isolating transformer.

Voltage transformers up to a maximum 5000:1 ratio may be used. The nominal secondary

voltage must be in the 50 to 240 V range.The three phase inputs are designated as the “bus

voltage”. The Bus VT connections most commonly used, wye and delta (or open delta), are

shown in the typical wiring diagram.

NOTE

NOTE: If Delta VTs are used, the zero sequence voltage (V0) and neutral/sensitive ground

polarizing voltage (–V0) will be zero. Also, with the Delta VT connection, the phase-neutral

voltage cannot be measured and will not be displayed.

NOTE

NOTE: The 350 relay can be applied to both metering and protection feeders with up to 550 kV

phase-to-phase voltage. Please ensure that the selected VT ratio and VT secondary do not

result in a primary voltage exceeding 550 kV.

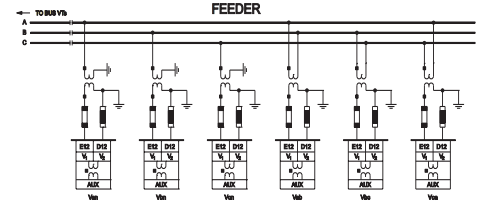

The single phase input is designated as the “Aux VT Input”. The Aux VT input channel can be

connected for either phase-neutral voltage Van, Vbn, Vcn, or for phase-phase voltage Vab,

Vbc, Vca as shown below.

Control power

CAUTION: Control power supplied to the relay must match the installed power supply range. If the

applied voltage does not match, damage to the unit may occur. All grounds MUST be

connected for safe, normal operation regardless of control power supply type.

The label found on the relay specifies its order code or model number. The installed power

supply’s operating range will be one of the following:

LO: 24 to 48 V DC (Range: 20 to 60 V DC)

HI: 125 to 250 V DC/120 to 240 V AC (Range: 84 to 250 V DC/60 to 300 V AC (50 and 60

Hz))

CAUTION: The relay should be connected directly to the ground bus, using the shortest practical

path. A tinned copper, braided, shielding and bonding cable should be used. As a

minimum, 96 strands of number 34 AWG should be used. Belden catalog number 8660

is suitable.

CAUTION: Isolate power prior to servicing.

An external switch, circuit breaker, or other protective device must be connected near to

the equipment

Contact inputs

External contacts can be connected to the relay’s ten (10) digital inputs. These contacts are

wet only.

The inputs can be programmed to different thresholds depending on the DC voltage (17,

33, 84, 166).

CAUTION: Ensure correct polarity on contact input connections and do not connect any contact

input circuits to ground or else relay hardware may be damaged.

A wet contact has one side connected to the positive terminal of an external DC power

supply. The other side of this contact is connected to the required contact input terminal. In

addition, the negative side of the external source must be connected to the relay’s DC

negative rail at Terminal C11. The maximum external source voltage for this arrangement

is 300 V DC.

Trip and Close output relays

The 350 relay is equipped with seven electromechanical output relays: two special relays

designed for Breaker trip and close (Relay 1 “Trip”, Relay 2 “Close”), four general purpose

relays (Auxiliary Relays 3 to 6), and a Critical Failure relay. The special purpose relays have

fixed operating characteristics and the general purpose relays can be configured by the

user.

Operation of the Trip and Close output relays is designed to be controlled by the state of

the circuit breaker as monitored by a 52a or 52b contact.

• The Trip and Close relays reset after the breaker is detected in a state corresponding

to the command. When a relay feature sends a command to one of these special

relays, it will remain operational until the requested change of breaker state is

confirmed by a breaker auxiliary contact and the initiating condition has reset.

• If the initiating feature resets, but the breaker does not change state, the output relay

will be reset after a default interval of 2 seconds.

• If neither of the breaker auxiliary contacts, 52a nor 52b, is programmed to a contact

input, the Trip Relay is de-energized after either the delay programmed in the Breaker

Failure feature, or a default interval of 100 ms after the initiating input resets. The

Close Relay is de-energized after 200 ms.

• If a delay is programmed for the Trip or Close contact seal-in time, then this delay is

added to the reset time. Note that the default setting for the seal-in time is 40 ms.

Breaker monitoring (Trip and Close coil monitoring) is performed by a built-in voltage

monitor on Form A output relays: #1 Trip, and #2 Close. The voltage monitor is connected

across each of the two Form A contacts, and the relay effectively detects healthy current

through the circuit. In order to do this, an external jumper must be connected between

terminals A2 and A3 for Trip coil monitoring, or/and B4, and B5 for Close coil monitoring.

As long as the current through the Voltage Monitor is above the threshold of the trickle

currents (see Technical Specification for Form A output relays), the circuit integrity for the

Trip (Close) coil is effectively normal. If the Trip (Close) coil circuit gets disconnected, or if in

general a high resistance is detected in the circuitry, a Trip (Close) alarm will be set and the

“ALARM” and “MAINTENANCE” LEDs will be on.

Example 1: The figures below show the two different connections of the breaker trip (close)

coil to the relay’s trip output #1 terminals (output #2 Close coil monitoring) for both no

voltage monitoring and voltage monitoring of the trip (close) circuit integrity.

NOTE

NOTE: To monitor the trip coil circuit integrity, use the relay terminals A2 and B3 to connect the

Trip coil, and provide a jumper between terminals A2 (optional voltage) and A3.

IRIG-B

IRIG-B is a standard time code format that allows time stamping of events to be

synchronized among connected devices within 1 millisecond. The IRIG time code formats

are serial, width-modulated codes which can be either DC level shift or amplitude

modulated (AM) form. The type of form is auto-detected by the 350 relay. Third party

equipment is available for generating the IRIG-B signal; this equipment may use a GPS

satellite system to obtain the time reference so that devices at different geographic

locations can also be synchronized.

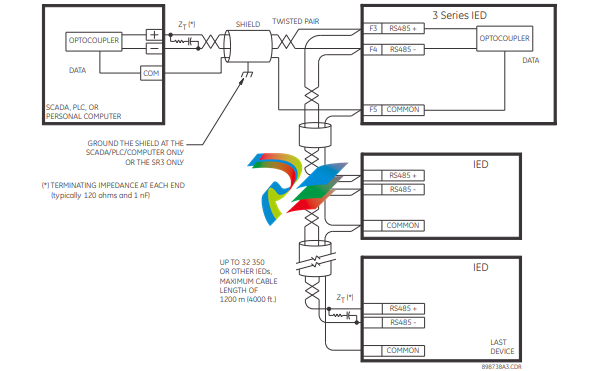

The uncovered communications cable shield connected to the common terminal should

not exceed 1” (2.5 cm) for proper EMC shielding of the communications cable.

350 Feeder Protection System

Chapter 3: Interfaces

Interfaces

There are two methods of interfacing with the 350 Feeder Protection System.

• Interfacing via the relay keypad and display.

• Interfacing via the EnerVista 3 Series Setup software.

This section provides an overview of the interfacing methods available with the 350 using

the relay control panels and EnerVista 3 Series Setup software. For additional details on

interface parameters (for example, settings, actual values, etc.), refer to the individual

chapters.

.png)

.png)

.png)