EMERSONWestinghouse E 20 Training From Normal Operation to Se lectric Belgium 14 Catalog vere Accident Management

THE 2014 WESTINGHOUSE TRAINING PROGRAM 1

TRAINING SCOPE

In addition to our engineering and site-service

activities, Westinghouse Electric Belgium

provides training services to customers in the

nuclear industry.

Starting from basic courses describing the

Pressurized Water Reactor (PWR), the training

scope extends to the plant operation field and

Emergency Operating Procedures (EOP’s).

Another area of expertise is represented by the

training courses on core damage mitigation and

severe accident management.

The courses contained in the 2014 training

catalog are arranged in five categories:

Operation and Accident Related Courses

Maintenance Courses

Engineering Courses

Accident-Based Seminars

AP1000

Particular effort is made to eliminate

redundancies and repetition between courses,

thus avoiding loss of time for attendees

participating in several courses.

TEACHING MATERIAL

The materials used to prepare and teach the

courses are based on regularly updated

Westinghouse documents issued by the

Westinghouse Training Organization.

During preparation of the courses, the

instructors have free access to any information

available in the Belgian Engineering Department

or in the US, which assures the high quality of

the technical content of our courses.

The teaching material includes PowerPoint

presentations but also the equipment mock-ups

located at the Field Services, and computer

software available in the Engineering

Department, when needed.

COURSE TEACHERS

The instructors used by the Belgian Training

Organization are drawn mostly from our Belgian

Engineering Department, from the staff of

engineers of the Field Services, or are from the

US training organization. All have demonstrated

instructional skills and practice. Their technical

knowledge is based on years of experience in

engineering and/or on-site jobs, as well as on

specific instructional training courses.

The excellent feedback received from attendees

attests the high level our instructors have attained

GENERAL COURSE ORGANIZATION

Our generic courses are provided on a yearly

basis, in English, and are open to all.

All courses are given in our Nivelles offices, in

Belgium.

Most of courses run for 6 hours a day, starting at

9:00 am.

In addition to our generic courses we also

provide plant specific courses, on site, according

to customer request or needs. This allows the

customer to enroll a large number of attendees

in the classroom which results in a price-perattendee reduction. In addition, the Belgian

Training Organization has a multi-language

capability which is to the benefit of attendees

who are not totally fluent in English.

INFORMATION AND REGISTRATION

Information forms are provided at the end of this

catalog. You may use these now or later in 2014

to receive additional information about a course.

Registration forms are also provided at the end

of the catalog. You may use them now or later in

2014 to reserve one or several seats on a

course.

CONTACTS

For any queries about our training program and

capabilities, please contact:

Nathalie Dessars

Manager

Safety Analysis & Risk Applications

Tel. 32-67.28.82.11

e-mail: dessarn@westinghouse.com

Annick Colignon

Training Administrator

Safety Analysis & Risk Applications

Tel. 32-67.28.82.19

CALENDAR FOR 2014 COURSES 5

The following agenda is liable to modification in case of coincidence between a generic course and a

customer specific training session. The courses for which no date is indicated will be organized upon

customer request.

Identification Title Dates

OPERATION AND ACCIDENT

OP 141 PWR Plant Systems Description and Operation 3-7 March

15-19 September

OP 142 PWR Plant Chemistry Upon request

OP 143 Transient and Accident Analysis 6-17 October

OP 144 Emergency Response Guidelines 20-24 October

OP 145 Core Damage Mitigation and Severe Accident Management 29 September -

3 October

OP 146 Dedicated TSC/STA Training for EOP Support 1-5 December

MAINTENANCE

MAIN 141 Reactor Coolant Pump Seal Maintenance and Inspection Upon request

ENGINEERING

ENG 141 ASME Code Familiarization Upon request

ENG 142 US-Nuclear Standards, Rules and Regulations Upon request

ENG 143 Fracture Mechanics Applications Upon request

ACCIDENT-BASED SEMINARS

ABS 141 Loss of Coolant Accident and Loss of All AC Power Accidents Upon request

ABS 142 Steam Generator Tube Rupture Upon request

ABS 143 Pressurized Thermal Shock Upon request

ABS 144 Fission Products Behavior During a Severe Accident Upon request

ABS 145 Emergency Plan Implementation During a Severe Accident Upon request

AP 1000 AP 1000 Upon request

PWR Accident Analysis and Mitigating Core Damage SNE560 15

Shift Technical Advisor (STA) Operational Applications SNE570 3

Shift Technical Advisor (STA) Training Seminars SNE580

Station Nuclear Engineer (SNE) Applications SNE594 15

Advanced Station Nuclear Engineer (SNE) Refresher SNE714

Online Station Nuclear Engineer (SNE) SNE800 12 weeks

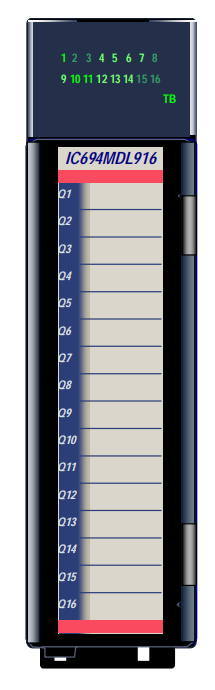

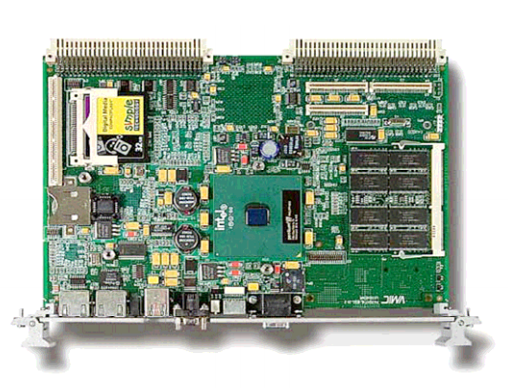

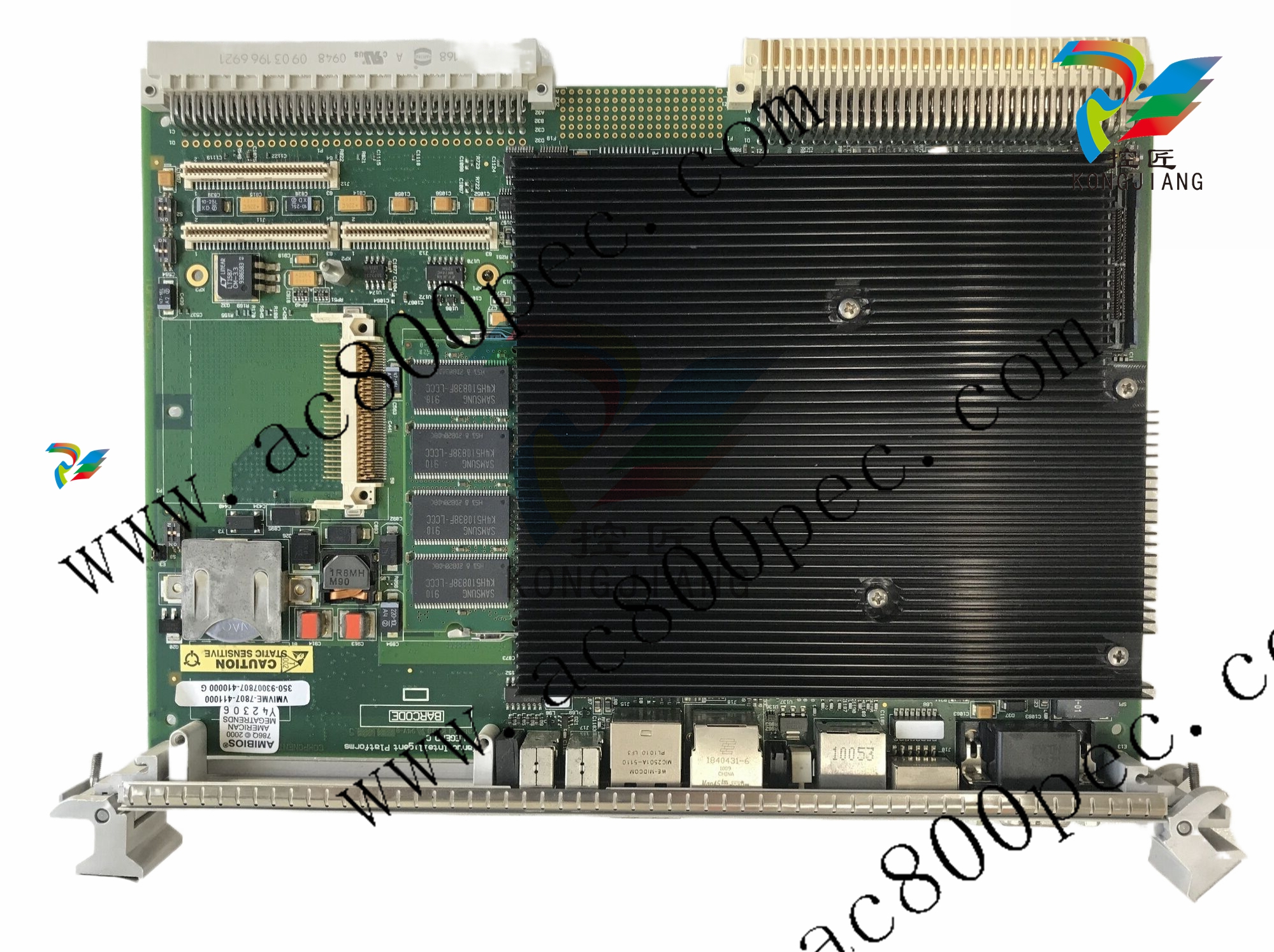

INSTRUMENTATION & CONTROL TRAINING

Title US Code # Days

Inadequate Core Cooling Monitor (ICCM-86) NIC275 10

RVLIS Hydraulics NIC276 5

Common Q Platform Overview NIC290 3

7300 Process Instrumentation NIC320 10

7300 Process Instrumentation Refresher NIC321 5

Nuclear Instrumentation System (NIS) NIC335 5

Nuclear Instrumentation System (NIS) Refresher NIC336 5

ONLINE – Nuclear Instrumentation System NIC337 10 weeks

Nuclear Instrumentation System Troubleshooting NIC338 5

Incore Instrumentation System NIC340 5

Solid State Protection System (SSPS) NIC350 10

Solid State Protection System (SSPS) Refresher NIC351 5

ONLINE – Solid State Protection System (SSPS) NIC352 10 weeks

Solid State Protection System (SSPS) Troubleshooting NIC353 5

Rod Control System (RCS) NIC355 10

Rod Control System (RCS) Refresher NIC356 5

ONLINE – Rod Control System (RCS) NIC357 10 weeks

Rod Control System (RCS) Troubleshooting NIC358 5

Digital Rod Position Indication System (DRPI) NIC360 5

7300 Process Instrumentation Scaling NIC380 5

Ovation System Overview OPC100 -

PWR PLANT SYSTEMS DESCRIPTION

AND OPERATION (OP 141)

Course Objectives

This course is designed to review the design

basis and layout of the major PWR plant

systems. The interactions between the different

systems and the overall plant integration are

particularly enhanced.

Exercises are foreseen in order to understand

systems operation.

Course Outline

DAY 1

Course Introduction

Introduction to Reactor Theory

Neutron physics principles and reactor

theory

Core feedback

Thermal hydraulics of the PWR core and

heat exchanger

DAY 2

Reactor Coolant System

Reactor vessel and core

Steam generator

Reactor coolant pump

Pressurizer

Chemical and Volume Control System

Make-up

Boron recycle

Boron thermal regeneration

Residual Heat Removal System

DAY 3

Balance of Plant Systems

Main steam and turbine

Main feedwater and condenser

Instrumentation & Control Systems

Resistance temperature detectors

Incore and excore nuclear instrumentation

Pressure, DP and level measurements

Rod control system

Steam dump

Pressurizer level and pressure control

Steam generator water level control

DAY 4

Plant Operation

Reactor Trip and Protection System

Actuation Logic

Engineered Safety Features Description

Emergency core cooling system

Auxiliary feedwater

Containment systems

DAY 5

Accident Analysis

FSAR

Technical Specification

Introduction to Emergency Operating

Procedures (EOP’s)

Introduction to Severe Accident Management

Guidelines (SAMG’s)

Questions and Answers

PWR PLANT CHEMISTRY (OP 142)

Course Objectives

The purpose of this course is to explain the

chemistry of the PWR, the problems that arise

during operation and the actions to be taken to

minimize the effects caused by these problems.

After an initial refresher on the basic principles

of nuclear power, the course proceeds with an

examination of the controls required for safe

long term operation and leads to a set of

specifications and actions aimed at maintaining

the required conditions.

On completion of the course, attendees will have

a full understanding of chemistry requirements

and how they are met.

Course Outline

DAY 1

Introduction and presentation of course

PWR chemistry and corrosion

PWR conventional and radiochemistry

Reactivity control, chemical shim and boron

chemistry

Reactor coolant crud

Tritium

DAY 2

Fission product poisoning

Primary chemistry specifications

Secondary side chemistry

SG primary water stress corrosion cracking

SG secondary side corrosion

Secondary side specifications

DAY 3

Secondary side specifications

Shutdown chemistry and radiochemistry

Operating experiences

Chemistry during abnormal conditions

Course summary and closure

Evaluation and feedback

TRANSIENT AND ACCIDENT ANALYSIS

(OP 143)

Course Objectives

The purpose of this course is to give the

attendees the feel for plant behavior during

normal, abnormal and accident transients.

Course Outline

FIRST WEEK

DAY 1

Course Introduction

Radiological Aspects of Core Damage

Fundamentals of Reactor Theory

DAY 2

Fundamentals of Reactor Theory (continued)

Introduction to Accident Analysis

DAY 3

Introduction to Accident Analysis (continued)

Reactivity Addition and Power Distribution

Anomaly Accidents

DAY 4

Increased Heat Removal by the Secondary

System Accidents

Reduced Heat Removal by the Secondary

System Accidents

DAY 5

Reduced Reactor Coolant Flow Accidents

Loss of Reactor Coolant Accidents

SECOND WEEK

DAY 1

Loss of Reactor Coolant Accidents

(continued)

Steam Generator Tube Rupture Accidents

DAY 2

Introduction to Mitigating Core Damage

Critical Safety Function:

Subcriticality

ATWS

DAY 3

Critical Safety Function:

Core Cooling

Inadequate Core Cooling

Critical Safety Function:

Heat Sink

Loss of Secondary Heat Sink

DAY 4

Critical Safety Function:

Primary Integrity

Pressurized Thermal Shock

Critical Safety Function:

Containment

Severe Accident Phenomenology

DAY 5

Severe Accident Phenomenology

(Continued)

Accident Response Instrumentation

EMERGENCY RESPONSE GUIDELINES

(OP 144)

Course Objectives

The purpose of this course is to explain the

background of the ERGs Rev. 2, and their use.

Emphasis is placed on understanding of

phenomena and recovery actions rather than

pure description of procedures.

Course Outline

DAY 1

Philosophy and structure of the ERGs

E-0 procedure and subprocedures

DAY 2

LOCA concerns

E-1, E-2 and subprocedures

DAY 3

Steam Generator Tube Rupture

E-3 and Subprocedures

DAY 4

ATWS

Inadequate Core Cooling

Loss of Feedwater

DAY 5

Pressurized Thermal Shock (PTS)

Containment Integrity

RCS Inventory

Total Loss of AC Power

Questions and Answers

CORE DAMAGE MITIGATION AND

SEVERE ACCIDENT MANAGEMENT

(OP 145)

Course Objectives

This course is designed to familiarize plant

operation personnel and staff members with

severe accident phenomena and accident

scenarios highlighting the recovery and

mitigation actions to prevent and limit core

damage, maintain containment integrity and

minimize the fission product releases. The

Severe Accident Management Guidelines

(SAMGs), developed by the Westinghouse

Owners Group, are presented and their link with

the Emergency Operating Procedures and the

Site Emergency Plan is explained.

Course Outline

Introduction

Definition of a severe accident

Description of Chernobyl, Three Mile

Island, and Fukushima Accidents

Tools for the Study of the Severe

Accidents

PSA Terminology and Scope

PSA Example Results

PSA Uses

PSA Decision Making Criteria

Severe Accident Simulation Models

Example Severe Accident Sequence

Introduction to Severe Accident

Management

Plant behavior prior to Core Damage:

Initiating Events, Emergency Operating

Procedures (EOPs)

Anticipated Transient Without Scram

(ATWS)

Loss of Coolant Accidents / Inadequate

Core Cooling (ICC)

Loss of Feedwater / Loss of Heat Sink

(LOHS)

Loss of AC Power

Severe Overcooling / Pressurized

Thermal Shock (PTS)

Response of Instrumentation to Core

Uncovery

Plant behavior during and after core damage:

in vessel phase

Behavior up to core uncovery

Core melt progression

Hydrogen generation

Natural circulation and creep failure

phenomena

Reactor vessel failure

Importance of EOPs and operator actions

Plant behavior during and after core damage:

ex- vessel phase

Containment design

Debris dispersal

Direct containment heating

Vessel thrust

Steam explosions

Debris coolability

Core concrete attack

Hydrogen behavior in containment

Containment fragility and failure modes

Radiological Aspects

Fission product inventory

Fission product release from fuel

Fission product transport

Source terms

Severe accident mitigation hardware

Filtered containment venting

Emergency containment spray system

Hydrogen control systems

Severe Accident Management Guidance –

WOG SAMG Overview

Background

Scope and philosophy

Technical basis

Goals

Structure of SAMG

Interface with EOPs and E-plan

Control room SAMG

TSC SAMG

Instrumentation

Phenomenology

Computational aids

Design variations

Summary

DEDICATED TSC/STA TRAINING

FOR EOP SUPPORT (OP 146)

Course Objectives

The purpose of this course is to provide the

necessary information to Technical Support

Center (TSC)/Shift Technical Adviser

(STA)/Plant Engineering Staff (PES) such that

they can provide adequate and effective support

to the operators during an accident recovery.

Course Approach

The teaching approach combined classic

presentations where the physical aspects of the

most important EOP recovery strategies are

presented and explained with Case Studies,

which put the attendees in situations for which

they have to come up with answers to operator

initiated questions or advises. The Plant

Engineering Staff (PES) Case Studies in the

following agenda are intended to provide

information on the possible evaluations that a

Technical Support Center (TSC), Shift Technical

Adviser (STA) or Plant Engineering Staff (PES)

would have to perform to support control room

operators in case of accidents. This includes

evaluations concerning:

RHR suction alignment

Need to transfer to hot leg recirculation

Establishing RCS letdown or not

Venting RV head or not

Post-SGTR cooldown method

Control of sump pH

SG overfill

Which SG to use for cooldown

Reinitiation of feed to a dry SG

RCP status

Long term plant status

Course Outline

DAY 1

Symptom-Based Emergency Operating

Procedures – Introduction

Diagnostic

SI Termination & Reinitiation Criteria

EOP Evaluations by TSC or Plant

Engineering Staff

Loss of Coolant Accident Physics in Relation

with Break Size

DAY 2

RCP Trip/Restart Criteria

SI Reduction Criteria

Case Study 1 – Small Break LOCA

Case Study 2 – Large Break LOCA

DAY 3

Shutdown LOCA

Case Study 3 – Stuck Open Safety Valve

Case Study 4 – LOCA Outside Containment

Pressurized Thermal Shock Aspects – FR-Ps

DAY 4

E-3, Steam Generator Tube Rupture

SGTR Contingencies

Case Study 5 – SGTR

Case Study 6 – Faulted & Ruptured SG

Return to power & ATWS

DAY 5

Case Study 7 – Anticipated Transient

Without Trip

Total Loss of Feedwater & Bleed and Feed

Case Study 8 – Loss of Secondary Heat Sink

Case Study 9 – Degraded and Inadequate

Core Cooling

Instrument Response in Accident Conditions

MAINTENANCE COURSES

MAIN 141: Reactor Coolant Pump Seal Maintenance and Inspection

REACTOR COOLANT PUMP SEAL

MAINTENANCE AND INSPECTION

(MAIN 141)

Course Outline

1. Theory and functional description of the

RCP

- 3 days: theoretical

- 2 days: practical

General description of the pump and

motor components

Description of the seal area

Flow paths

Internal

External - Interface with CCW

- Injection water

Auxiliary equipment

Pump side: filters, standpipe

Motor side: oil lift system

Bearing system

2. Walk through the total inspection program

(classroom phase)

Dismounting technique of seals

Discussion of

Why to inspect

How to inspect

Inspection intervals

Inspection technique

Inspection criteria

Monitoring of seals

3. Practical training in dismounting/erection

Practical demonstration of seals

dismounting/erection following the

manual

The purpose is to apply the theoretical

aspects reviewed on the first day.

The exercise will be done on the ESC

mock-up using the adequate tools and

equipment.

4. Practical performance of inspection

program

This session is dedicated to the practical

performance of dismounting/remounting

and seals inspection on the ESC mock-up.

Each person will have the opportunity to

handle the equipment under the lead of

instructors.

5. Theoretical description of motor to pump

alignment

Centering of pump (on Mock-Up)

Swing check

Oil lift

Axial end play

Discussion of tooling used and

modifications

Conclusion and open discussion

ENGINEERING COURSES

ENG 141: ASME Code Familiarization

ENG 142: US-Nuclear Standards, Rules and Regulations

ENG 143: Fracture Mechanics Applications

ASME CODE FAMILIARIZATION

(ENG 141)

Course Objectives

The purpose of the course is to present the

background and history of the ASME code for

boiler and pressure vessel design and

construction. Specific attention is also paid to

the organization and use of the code. At the end

of the course the attendees will be able to

manipulate the ASME code for their own

application.

Practical workshops are foreseen to enhance

code utilization.

Course Outline

DAY 1

What is the ASME code?

General introduction to the ASME B&PV

Code

Comparison and relationship with other

US and European Codes: ANSI, ASTM,

AWS, ASNT, French RCCM, German

KTA

Administration of the ASME Code and

organization of the Code editions and

addenda.

Why was the Code introduced and how is it

applied in the nuclear industry?

Significant events in the USA

References to US Code of Federal

Regulations (CFR) and NRC Regulatory

Guides

Design Basis and the Code

Adaptation and use of the ASME Code in

European countries. Position of the

respective National Regulatory Bodies.

How is the ASME code organized?

Detailed content of the ASME B&PV code

Definitions

Organization in sections

Organization in subsections and articles

Interpretations and Code cases

Relationship between the different parts of

the Code

Nuclear Power Plant components:

definition of and relationship between

ANSI Safety Classification and ASME

Code Class

Workshop on the general Code structure and

use.

DAY 2

Specific presentation of the Code sections of

main interest to the Nuclear Power Industry

Section II Material Specifications

(Ferrous, Nonferrous and Welding

Materials)

Section III Subsection NCA

Scope of each Subsection

Structure in Articles (1000 to 8000)

Subsection NB: Class 1 Components

Article 2000 (Material)

Article 3000 (Design)

Article 4000 (Fabrication and

Installation)

Article 5000 (Examination)

Article 6000 (Testing)

Subsections NC, ND: Class 2 and 3

Components

Subsection NF: Component Supports

Subsection NG: Core Support Structures

Specific presentation of the Code section III

Article NB-3000 (Class 1 Components

Design)

This presentation will address the

concepts and background applied in

NB-3000: General Design, Design by

Analysis (i.e. NB-3200, stress categories

and respective limits), Design by Rules

(e.g. NB-3600 Piping)

Purpose, meaning and details of specific

equations will be presented (e.g. NB-3600

Class 1 fatigue analysis)

Workshop on the use and application of

ASME III subsection NB.

DAY 3

Specific presentation of the Code sections

Section V: Nondestructive Examination

NDE methods and actual records will be

presented to the attendees

Section VIII: Pressure Vessel, relation and

difference with Section III

Section IX: Welding and Brazing

Qualifications

Introduction to Fracture Mechanics concepts

and their application in ASME III Appendix G,

ASME XI, and 10CFR50 Appendix G

Section XI: In-service Inspection of NPP

Components.

Exercises on Section XI application

Summary overview of the Code usage

through the component life (design,

inspection, repair, fatigue monitoring)

Current development of the Code, NRC

position, European Regulators position

US-NUCLEAR STANDARDS, RULES

AND REGULATIONS (ENG 142)

Course Objectives

This course will provide an overview of the

nuclear rules, regulations and standards,

currently applicable in the US and followed in

many other Western countries.

Their application in licensing during construction

and operation of a nuclear power plant will be

discussed.

Aspects of safety classifications, qualification,

quality assurance programs, maintenance and

inspection, and rules of backfitting are included

in the program.

The US rules presented will be compared

samplewise with other international regulations.

This course is addressed to people looking for

an introduction to Western nuclear standards. It

can serve as a preparation for specialized

courses (for example on the ASME-Code).

Course Outline

DAY 1

Safety objectives

Licensing process

Introduction to US rules and regulations

Policy statements

Regulations

Regulatory guides and standard review plan

National standards

Industry practice

Other NRC documents

Compliance with regulatory requirements

Safety classification

DAY 2

Seismic classification

QA classification

Classification for electrical and I&C

equipment

Application of safety classes and ASME code

for mechanical equipment

Application of safety classes and IEEE

standards for electrical equipment

Qualification of electrical and I&C equipment

Software qualification

QA program requirements

Backfitting and upgrading