EMERSONIPMC7126E/7616E I/O Module

SCSI Type Width Speed

FAST SCSI Narrow (8 bit) 10MB/second

FAST SCSI Wide (16 bit) 20MB/second

Ultra SCSI Narrow (8 bit) 20MB/second

Ultra SCSI Narrow (16 bit) 40MB/second

Trademarks

Emerson, Business-Critical Continuity, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of

Emerson Electric Co. © 2008 Emerson Electric Co.

All other trademarks are the property of their respective owners.

PICMG®, CompactPCI®, AdvancedTCA™ and the PICMG, CompactPCI and AdvancedTCA logos are registered trademarks of the PCI Industrial

Computer Manufacturers Group.

Notice

While reasonable efforts have been made to assure the accuracy of this document, Emerson assumes no liability resulting from any omissions

in this document, or from the use of the information obtained therein. Emerson reserves the right to revise this document and to make changes

from time to time in the content hereof without obligation of Emerson to notify any person of such revision or changes.

Electronic versions of this material may be read online, downloaded for personal use, or referenced in another document as a URL to a Emerson

website. The text itself may not be published commercially in print or electronic form, edited, translated, or otherwise altered without the

permission of Emerson,

It is possible that this publication may contain reference to or information about Emerson products (machines and programs), programming, or

services that are not available in your country. Such references or information must not be construed to mean that Emerson intends to announce

such Emerson products, programming, or services in your country.

Limited and Restricted Rights Legend

If the documentation contained herein is supplied, directly or indirectly, to the U.S. Government, the following notice shall apply unless otherwise

agreed to in writing by Emerson.

Use, duplication, or disclosure by the Government is subject to restrictions as set forth in subparagraph (b)(3) of the Rights in Technical Data

clause at DFARS 252.227-7013 (Nov. 1995) and of the Rights in Noncommercial Computer Software and Documentation clause at DFARS

252.227-7014 (Jun. 1995).

Contact Address

Emerson Network Power - Embedded Computing

2900 South Diablo Way, Suite 190

Tempe, AZ 85282

USA

Safety Summary

The following general safety precautions must be observed during all phases of operation, service, and repair

of this equipment. Failure to comply with these precautions or with specific warnings elsewhere in this manual

could result in personal injury or damage to the equipment.

The safety precautions listed below represent warnings of certain dangers of which Emerson is aware. You,

as the user of the product, should follow these warnings and all other safety precautions necessary for the

safe operation of the equipment in your operating environment.

Ground the Instrument.

To minimize shock hazard, the equipment chassis and enclosure must be connected to an electrical ground.

If the equipment is supplied with a three-conductor AC power cable, the power cable must be plugged into

an approved three-contact electrical outlet, with the grounding wire (green/yellow) reliably connected to an

electrical ground (safety ground) at the power outlet. The power jack and mating plug of the power cable meet

International Electrotechnical Commission (IEC) safety standards and local electrical regulatory codes.

Do Not Operate in an Explosive Atmosphere.

Do not operate the equipment in any explosive atmosphere such as in the presence of flammable gases or

fumes. Operation of any electrical equipment in such an environment could result in an explosion and cause

injury or damage.

Keep Away From Live Circuits Inside the Equipment.

Operating personnel must not remove equipment covers. Only Factory Authorized Service Personnel or other

qualified service personnel may remove equipment covers for internal subassembly or component

replacement or any internal adjustment. Service personnel should not replace components with power cable

connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To

avoid injuries, such personnel should always disconnect power and discharge circuits before touching

components.

Use Caution When Exposing or Handling a CRT.

Breakage of a Cathode-Ray Tube (CRT) causes a high-velocity scattering of glass fragments (implosion). To

prevent CRT implosion, do not handle the CRT and avoid rough handling or jarring of the equipment.

Handling of a CRT should be done only by qualified service personnel using approved safety mask and

gloves.

Do Not Substitute Parts or Modify Equipment.

Do not install substitute parts or perform any unauthorized modification of the equipment. Contact your local

Emerson representative for service and repair to ensure that all safety features are maintained.

Observe Warnings in Manual.

Warnings, such as the example below, precede potentially dangerous procedures throughout this manual.

Instructions contained in the warnings must be followed. You should also employ all other safety precautions

which you deem necessary for the operation of the equipment in your operating environment.

Warning

Warning To prevent serious injury or death from dangerous voltages, use

extreme caution when handling, testing, and adjusting this

equipment and its components.

Flammability

All Emerson PWBs (printed wiring boards) are manufactured with a flammability rating of 94V-0 by UL-recognized

manufacturers.

EMI Caution

!

Caution

Caution This equipment generates, uses and can radiate electromagnetic energy. It may cause or be

susceptible to electromagnetic interference (EMI) if not installed and used with adequate EMI

protection.

CE Notice (European Community)

!

Warning

Warning This is a Class A product. In a domestic environment, this product may cause radio

interference, in which case the user may be required to take adequate measures.

Emerson products with the CE marking comply with the EMC Directive (89/336/EEC). Compliance with this directive

implies conformity to the following European Norms:

EN55022 “Limits and Methods of Measurement of Radio Interference Characteristics of Information

Technology Equipment”; this product tested to Equipment Class A

EN 300 386 V.1.2.1 “Electromagnetic compatibility and radio spectrum matters (ERM);

Telecommunication network equipment; Electromagnetic compatibility (EMC) requirements”

Board products are tested in a representative system to show compliance with the above mentioned requirements.

A proper installation in a CE-marked system will maintain the required EMC/safety performance.

In accordance with European Community directives, a “Declaration of Conformity” has been made and is on file

within the European Union. The “Declaration of Conformity” is available on request. Please contact your sales

representative.

The product has been designed to meet the directive on the restriction of the use of certain hazardous substances

in electrical and electronic equipment (RoHS) Directive 2002/95/EC.

Industrie Canada

This product meets the requirements of the Canadian Interference-Causing Equipment Standard ICES-003.

Cet appareil numérique est conforme à la norme NMB-003 du Canada

The IPMC7126E/7616E I/O Module Installation and Use manual provides the information you

will need to install, use, and program your IPMC7126E or IPMC7616E module. These are

optional I/O modules installed on the variants of the MVME5100, MVME5500 and MVME6100

Single Board Computers (SBCs). Their design utilizes the PowerPlus II architecture. Hereafter,

the IPMC7126E and IPMC7616E modules will be referred to as the IPMC712 and IPMC761.

The IPMC712 is a variation of the IPMC761 The primary differences between the two modules

are in the physical interfaces of the Ethernet port and serial ports 3 and 4. These differences

along with others are discussed in the following chapters of this manual.

As of the printing date of this manual, these I/O module models are available:

This manual is organized as follows:

■ Chapter 1, Product Features

■ Chapter 2, Installing the IPMC Module

■ Chapter 3, Programming

■ Chapter 4, Connector Pin Assignments

■ Appendix A, Specifications

■ Appendix B, Related Documentation

Summary of Changes

See the table below for manual revisions and changes.

Model Number Product Description and I/O Features

IPMC7126E-002 Multifunction rear I/O PMC module; Ultra-Wide SCSI, one parallel port,

three asynchronous and one synchronous/asynchronous serial port

IPMC7616E-002 Multifunction rear I/O PMC module; Ultra-Wide SCSI, one parallel port,

two asynchronous and two synchronous/asynchronous serial ports

See the table below for manual revisions and changes.

Model Number Product Description and I/O Features

IPMC7126E-002 Multifunction rear I/O PMC module; Ultra-Wide SCSI, one parallel port,

three asynchronous and one synchronous/asynchronous serial port

IPMC7616E-002 Multifunction rear I/O PMC module; Ultra-Wide SCSI, one parallel port,

two asynchronous and two synchronous/asynchronous serial ports

Part Number Date Description

6806800A45B September 2008 Update document to Emerson style (logo, copyright,

trademarks, etc.)

Comments and Suggestions

We welcome and appreciate your comments on our documentation. We want to know what you

think about our manuals and how we can make them better.

Mail comments to us by filling out the following online form:

http://www.emersonnetworkpowerembeddedcomputing.com/ > Contact Us > Online Form

In “Area of Interest” select “Technical Documentation”. Be sure to include the title, part number,

and revision of the manual and tell us how you used it.

Terminology

A character precedes a data or address parameter to specify the numeric format, as follows (if

not specified, the format is hexadecimal. An asterisk (#) following a signal name for signals that

are level significant denotes that the signal is true or valid when the signal is low.

An asterisk (#) following a signal name for signals that are edge significant denotes that the #

actions initiated by that signal occur on high to low transition.

In this manual, assertion and negation are used to specify forcing a signal to a particular state.

In particular, assertion and assert refer to a signal that is active or true; negation and negate

indicate a signal that is inactive or false. These terms are used independently of the voltage

level (high or low) that they represent.

Data and address sizes are defined as follows:

Conventions Used in This Manual

The following typographical conventions are used in this document:

bold

is used for user input that you type just as it appears; it is also used for commands, options

and arguments to commands, and names of programs, directories and files.

italic

is used for names of variables to which you assign values. Italic is also used for comments

in screen displays and examples, and to introduce new terms.

0x Specifies a hexadecimal number

% Specifies a binary number

& Specifies a decimal number

Byte 8 bits, numbered 0 through 7, with bit 0 being the least significant.

Half word 16 bits, numbered 0 through 15, with bit 0 being the least significant.

Word 32 bits, numbered 0 through 31, with bit 0 being the least significant.

Double word 64 bits, numbered 0 through 63, with bit 0 being the least significant.

Conventions Used in This Manual

The following typographical conventions are used in this document:

bold

is used for user input that you type just as it appears; it is also used for commands, options

and arguments to commands, and names of programs, directories and files.

italic

is used for names of variables to which you assign values. Italic is also used for comments

in screen displays and examples, and to introduce new terms.

is used for system output (for example, screen displays, reports), examples, and system

prompts.

<Enter>, <Return> or <CR>

represents the carriage return or Enter key.

Ctrl

represents the Control key. Execute control characters by pressing the Ctrl key and the

letter simultaneously, for example, Ctrl-d.

Product Features

The IPMC712 and IPMC761 are optional modules that provide backward compatibility with

earlier Emerson products using the MVME761 or MVME712M rear transition modules.

General Functionality

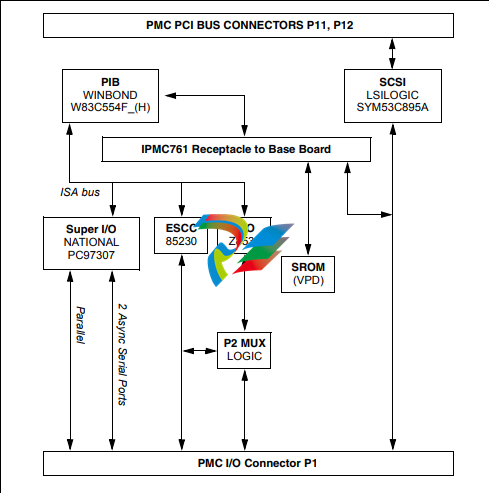

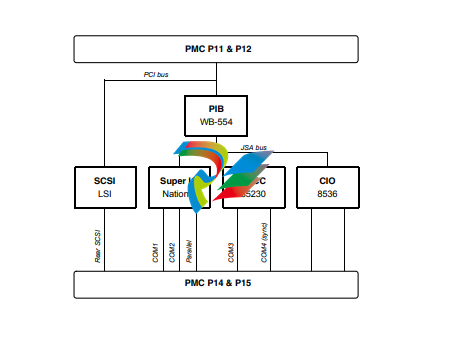

Both models are designed around a PMC form factor and both modules incorporate a PCI-toISA bridge, Ultra-wide SCSI adapter, and Super I/O functionality. Both modules are single wide,

standard length, standard height PMC boards. They attach to the host board PCI bus via the

PMC P11, P12, P13, P14, and P15 connectors.

■ One single-ended ultra-wide SCSI port

■ One parallel port

■ Four serial ports (2 or 3 asynchronous and 1 or 2 synchronous/asynchronous, depending

on the module)

With this PMC card configuration, the memory mezzanine, one PMC slot, and the PMCspan

are still available, providing support for additional product customization.

IPMC Mode

In IPMC mode, the MVME 6100, MVME5500, and MVME5100 support legacy MVME761 or

MVME712M rear transition modules (with limited PMC I/O) when an IPMC712 or IPMC761

module is installed in PMC slot 1. In this configuration, signals used by wide (16-bit SCSI

conflict with signals that are used by PMC slot 2 rear I/O.

Design Features

The following sections describe the basic features that are incorporated in the design of both

IPMC modules.

PCI Bus Interface

Both modules contain four EIA-E700 AAAB connectors, which provide a 32-bit PCI interface to

an IEEE P1386.1 PMC-compliant host board such as the MVME6100, MVME5500, or

MVME5100.

Connectors P11-P13 on each module provid

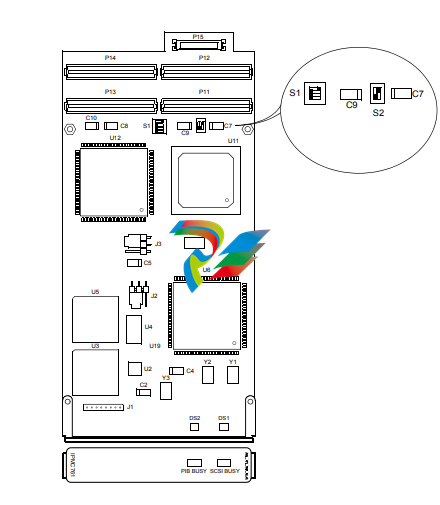

Configurable Switches

S1 Switch

A 1x4 switch (S1) is provided on each module for configuring GPIO pins 2 and 3. The factory

default setting is for Ultra-Speed and Ultra-Wide SCSI. Refer to Table 3-1 on page 16 for the

GPIO pin assignments and to Figure 3-1 on page 16 for the default switch settings.

S2 Switch

There is a 1x2 switch (S2) on each module that is in line with the PCI-to-ISA bridge for selecting

either AD[11] IDSEL or IDSELB for connection to the Winbond chip, depending on the IPMC

module you are using.

Note The S2 is not dependent on either IPMC module. It is dependent on either the

MVME5100, MVME5500, or MVME6100 host board. The IPMC modules are shipped

configured for these boards.

Details on IDSEL mapping and PCI arbitration assignments for these SBCs can be found in

Chapter 3, Programming. An illustration showing the S2 switch settings can be found in Figure

3-2 on page 17.

PCI-to-ISA Bridge (PIB)

The PIB provides the bridging functions between PCI local bus and the ISA local resource bus.

The following are a few of the features of the PIB.

SCSI

The SCSI controller is an LSI Logic SYM53C895A device. The SCSI clock frequency is 40 MHz.

The SCSI controller features:

■ 32-bit PCI Interface with 64-bit addressing

■ 8KB internal SCRIPTS RAM

■ Improved PCI caching design (improves PCI bus efficiency)

The SCSI device maintains backward compatibility with the MVME761 rear transition module

and P2 adapter card. It is also Ultra-wide capable and has a performance of 40MB/s

synchronous transfer rate across a 16-bit bus.

Note SCSI signals leading to connector P15 go through zero ohm resistors (R92-R100) before

terminating at P15. When the host board’s PMC slot 2 is populated, and there is an IPMC

module in slot 1, there exists a possibility for contention on these signals.

Figure 1-1. IPMC761 with Default Switch Setting

Table 1-1. IPMC761 Jumpers

Jumper Description Setting

J1 Reserved 9PLD programming

header

N/A

J2 Port 3 Transmit Clock 1-2: driven by IPMC761

2-3: received by IPMC761

J3 Port 4 Transmit Clock 1-2: driven by IPMC761

2-3: received by IPMC761

Figure 1-2. IPMC761 Functional Block Diagram

Figure 1-3. IPMC712 with Default Switch Settings

Table 1-2. IPMC712 Jumpers

Jumper Description Setting

J1 Reserved 9PLD programming

header

N/A

J2 Port 4 Receive Clock 1-2: driven by IPMC712

2-3: received by IPMC712

J3 Port 4 Transmit Clock 1-2: driven by IPMC712

2-3: received by IPMC712

J5 Clock Loopback MAX207 14/15in connects to R1out

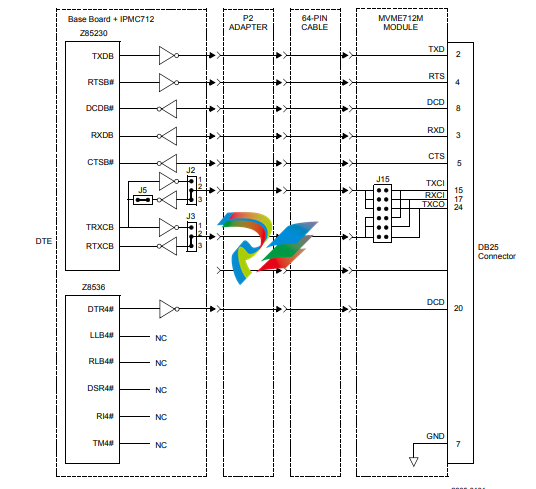

Figure 1-4. IPMC712 Functional Block Layout

Figure 1-5. IPMC712 Serial Port 4 Clock Configuration

ISA Local Resource Bus

PCI-to-ISA Bridge (PIB)

The PIB (W83C554F) contains the ISA Bridge I/O Registers necessary for various functions.

These registers are also accessible from the PCI bus.

Super I/O

The Super I/O device (PC97307) provides the following functions on the IPMC:

■ Two synchronous serial ports (COM1 and COM2)

■ Parallel printer port

ESCC

Two DTE synchronous/asynchronous serial ports are provided by the ESCC device (Z85230).

Since the Z85230 device does not have all modem control lines, a Z8536 CIO device (described

below) is used to provide the missing lines.

A PAL device is used to perform decode for the Z85230 and the Z8536 for register accesses

and pseudo interrupt acknowledge cycles in the ISA I/O space. DMA supports for the Z85230

is provided by the PIB.

The clock input to the Z85230 PCLK pin is a 10 MHz clock. The Z85230 supplies an interrupt

vector during a pseudo interrupt acknowledge cycle. The vector is modified based upon the

interrupt source within the device.

All modem control lines from the ESCC are multiplexed/demultiplexed through connector P2 by

the P2MX function due to pin limitation of the connector.

CIO

The CIO device (Z8536) is used to provide the modem control lines not provided by the Z85230

ESCC. In addition, the device has three independent 16-bit counters/timers. The clock input to

the Z8536 PCLK pin is a 5 MHz clock.

Static ROM (SROM)

Both modules contains one +3.3V, 256 x 8 serial EEPROM device (AT24C02) onboard. This

device provides for Vital Product Data (VPD) storage of the module hardware configuration. The

serial EEPROM is located on the baseboard’s I2C bus at address $A4.

Input/Output Modes

Both modules are designed to be plugged into PMC slot 1 of the base board. As stated earlier,

these SBCs have two P2 I/O modes (IPMC and PMC) that are user configurable. The user

should configure the baseboard for the IPMC module being used.

The jumpers route the on-board Ethernet port 2 to row C of connector P2. When used, both

modules are backwards compatible with the MVME761 rear transition module and P2 adapter

card (excluding PMC I/O routing) used on the MVME2600/2700. The rear panel Ethernet is not

available when using the IPMC712.

LEDs

Both modules use two LEDs to provide PMC status.

■ The module’s green SCSI LED is lit when the SCSI device is Master

■ The module’s green PIB LED is lit when the PCI bus grant to the PIB is asserted

PCI Signaling Voltage Level

Both modules will operate with only +5V signaling levels.

RS232 Interface

On the IPMC712 module, the four serial ports are used to communicate at RS232 voltage levels

(P14). The first three ports are fixed asynchronous ports, while the remaining port can be

configured as either a synchronous or an asynchronous port.

For additional handshaking signals, the IPMC712 module has the following features:

■ Port 1 has RTS and CTS

■ Ports 2, 3, and 4 have RTS, CTS, DTR, DCD

■ Port 4 has configurable serial clock signals RTxC and TRxC

Jumpers J2, J3 and J5 determine the sources for these two signals, refer to Figure 1-5 on

page 7.

This chapter discusses the configuration and installation of IPMC modules on an MVME6100,

MVME5500, or MVME5100 SBCs.

For additional information pertaining to the MVME51005E, refer to the information contained in

the MVME51005E Single Board Computer Installation and Use manual before proceeding with

these instructions contained in this chapter.

Packaging

As a precautionary measure, IPMC modules are sealed in an anti-static package to protect

them from static discharge. Observe standard handling practices of static sensitive equipment.

Configuring the IPMC Modules

There are two user configurable switches on the IPMC712 and IPMC761 I/O modules. Switches

S1 and S2 are described in Chapter 3, Programming.

Installing IPMC Modules on Host Board

Both the IPMC712 and the IPMC761 modules are installed on PMC slot 1 of the host board. As

a general reminder, IPMC modules must be installed on the host board prior to installing it into

the VME chassis.

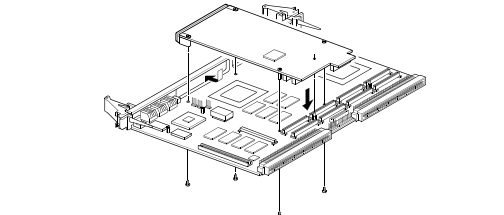

To install an IPMC module, refer to the following figure and proceed as follows:

1. Inspect the host board and the IPMC module for evidence of any damage to the PCB itself or

for evidence of any damage on the mating connectors.

2. If the host board is installed in a VMEbus card slot, carefully remove it and place it with

connectors P1and P2 facing you.

3. Remove the filler plate from the host board’s front panel. Position the IPMC module over the

center area of the slot 1 connectors as follows:

Figure 2-1. IPMC Installation

4. Line up the IPMC module’s front panel into the IPMC filler cutout slot on the host board’s front

panel.

5. Align connectors P11, P12, P13, P14, and P15 on the IPMC module with the mating connectors

on the host board and press firmly into place.

6. Insert the appropriate number of Phillips screws (typically 4) from the bottom of the host board

into the standoffs on the IPMC module and tighten the screws.

The host board is now ready to be installed into a VME chassis

Before You Install or Remove a Board

Boards may be damaged if improperly installed or handled. Please read and follow the

guidelines in this section to protect your equipment.

Observe ESD Precautions

Use ESD

Wrist Strap

ESD Emerson strongly recommends that you use an antistatic wrist strap and a conductive

foam pad when installing or upgrading a system. Electronic components, such as disk

drives, computer boards, and memory modules, can be extremely sensitive to

electrostatic discharge (ESD). After removing the component from its protective

wrapper or from the system, place the component flat on a grounded, static-free

surface (and, in the case of a board, component side up). Do not slide the component

over any surface.

If an ESD station is not available, you can avoid damage resulting from ESD by wearing

an antistatic wrist strap (available at electronics stores) that is attached to an active

electrical ground. Note that a system chassis may not be grounded if it is unplugged.

Watch for Bent Pins or Other Damage

!

Caution

Caution Bent pins or loose components can cause damage to the board, the backplane, or

other system components. Carefully inspect your board and the backplane for both pin

and component integrity before installation.

ECC and our suppliers take significant steps to ensure there are no bent pins on the backplane

or connector damage to the boards prior to leaving our factory. Bent pins caused by improper

installation or by boards with damaged connectors could void the warranty for the backplane or

boards.

If a system contains one or more crushed pins, power off the system and contact your local

sales representative to schedule delivery of a replacement chassis assembly.

Use Caution When Installing or Removing Boards

When first installing boards in an empty chassis, we recommend that you start at the left of the

card cage and work to the right when cards are vertically aligned; in horizontally aligned cages,

work from bottom to top.

When inserting or removing a board in a slot adjacent to other boards, use extra caution to avoid

damage to the pins and components located on the primary or secondary sides of the boards.

Preserve EMI Compliance

!

Caution

Caution To preserve compliance with applicable standards and regulations for electromagnetic

interference (EMI), during operation all front and rear openings on the chassis or board

faceplates must be filled with an appropriate card or covered with a filler panel. If the

EMI barrier is open, devices may cause or be susceptible to excessive interference.

Recognize Different Injector/Ejector Lever Types

The modules you install may have different ejector handles and latching mechanisms. The

following illustration shows the typical board ejector handles used with ECC payload cards: (A)

Elma Latching, (B) Rittal Type II, (C) Rittal Type IV. All handles are compliant with the

CompactPCI specification and are designed to meet the IEEE1101.10 standards.

Each lever type has a latching mechanism to prevent the lever from being opened accidentally.

You must press the lever release before you can open the lever. Never force the lever. If the lever

does not open easily, you may not have pressed firmly enough on the release. If the lever does

not close easily, the board may not be properly seated in the chassis.

To open a lever, press the release and move the lever outward away from the faceplate.

To close a lever, move the lever inward toward the faceplate until the latch engages.

Verify Slot Usage

!

Caution

Caution Prevent possible damage to module components by verifying the proper slot usage for

your configuration.

Figure 2-2. Injector/Ejector Lever Types

Programming

Programing Details

The overall design of the IPMC712 and IPMC761 is based on the PowerPlus II architecture. The

programming characteristics for both modules conforms to the PowerPlusII Programming

Specification.

Note The PowerPlus II Programming Specification covers a large variety of programming

configurations, many of which are not applicable to either module. This chapter describes those

aspects of the specification that are unique to both modules.

PCI Local Bus

The on-board PCI devices on the IPMC712 and the IPMC761 are the PCI-to-ISA Bridge and

the SCSI controller.

The PCI-to-ISA Bridge (PIB)

The PCI-to-ISA Bridge (PIB) provides the bridging functions between PCI local bus and the ISA

local resource bus. Other features contained in the PIB are:

■ 8259 Interrupt Controller

■ ISA DMA support

■ Timers and counters

The SCSI Controller

The SCSI controller’s clock speed is 40 MHz. The presence of the SCSI device can be positively

determined by reading the Device ID PCI Configuration Register 0x02 - 0x03. The Device ID is

0x0012.

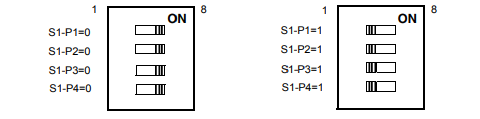

The General Purpose I/O (GPIO) pin assignments for the SCSI Controller are shown in the

table below. A 1x4 switch (S1) is provided to configure GPIO pins 2 and 3. The factory default

setting shall be for Ultra-Speed and Ultra-Wide SCSI.

The General Purpose I/O (GPIO) pin assignments for the SCSI Controller are shown in the

table below. A 1x4 switch (S1) is provided to configure GPIO pins 2 and 3. The factory default

setting shall be for Ultra-Speed and Ultra-Wide SCSI.

SW1-P1 controls GPIO2 (Ultra/FAST SCSI) and SW1-P2 controls GPIO3 (Wide/Narrow SCSI

bus. SW1-P3 and SW1-P4 are No Connect. Select the SCSI characteristics of your

configuration according to the following table:

Table 3-1. GPIO Pin Assignments

GPIO Pin Direction Level Usage

GPIO1_MASTER_l output 1 SCSI LED; SCSI is not MASTER.

0 SCSI is MASTER.

GPIO2 input 1 SCSI speed; selectable by switch S1.

S1:1 OFF selects Ultra

0 S1:1 ON selects FAST (default).

GPIO3 input 1 SCSI bus width; selectable by switch S1.

S1:2 in OFF selects Wide-SCSI.

0 S1:2 in ON selects Narrow-SCSI.

0, 4, 5, 6, 7, 8 - - Not used

Table 3-2. SCSI Speed/Width Settings Using GPIO2:[1,2]

Figure 3-1. GPIO Switch Settings (S1)

SW1-P1 controls GPIO2 (Ultra/FAST SCSI) and SW1-P2 controls GPIO3 (Wide/Narrow SCSI

bus. SW1-P3 and SW1-P4 are No Connect. Select the SCSI characteristics of your

configuration according to the following table:

Width of Bus Ultra (P1 OFF) Fast (P1 ON)

Wide (16-bit) SCSI bus (P2 OFF) 40MB/second 20MB/second

Narrow (8-bit) SCSI bus (P2 ON) 20MB/second 10MB/second

.png)

.png)

.png)