WATLOWMLS300 Series User’s Guide

the entire unit (or just the AIM cards) if necessary.

1. Choose an appropriate place to install the MLS300-AIM.

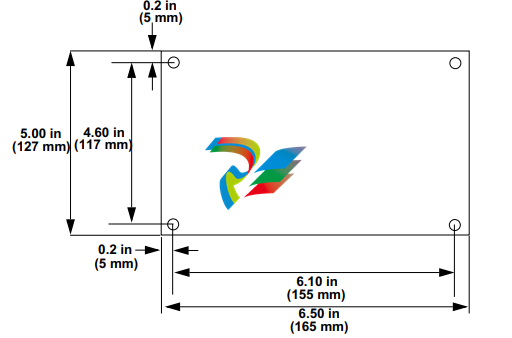

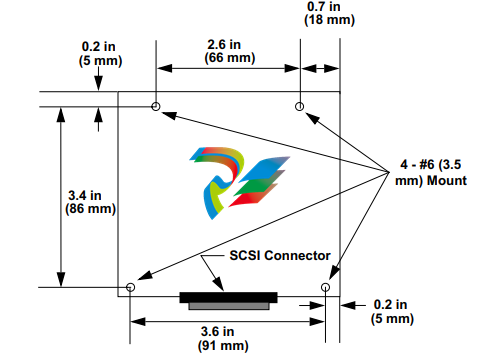

2. Use the template shown in Figure 2.7 as a reference for

clearance and dimensions.

Figure 2.7 MLS300-AIM Template

3. Drill four holes for #6 or #8 screws in the chosen

location.

4. Place the MLS300-AIM where you will mount it. Use

screws with internal star lock washers to ensure a good

Frame Ground connection. You may use self-tapping

screws. Insert the screws through the standoffs and

tighten them.

5. Be sure to remove any loose metal filings after you are

finished mounting the MLS300-AIM.

Mounting the CIM300

!

NOTE! If you plan to install scaling resistors, mount

them on the CIM300 before mounting the

CIM300 in the panel. See Chapter 9, Troubleshooting and Reconfiguring.

If you ordered a CIM300 with scaling inputs from Watlow

Anafaze, the scaling resistors are already installed.

Install the CIM300 in a location free from excessive (more

than 50ºC) heat, dust and unauthorized handling. The CIM300

measures 7.5 L x 2.75 W x 3.75 inches D. Leave 1.5 inches of

clearance above the CIM300, so that there will be enough

space for power and communications wires.

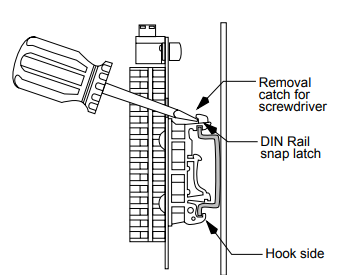

DIN Mounting

1. Choose an appropriate place to install the CIM300.

2. Snap the CIM300 on to the DIN rail by placing the hook

side on the rail first, then pushing the snap latch side in place.

(To remove the CIM300 from the rail, use a flat-head screw

driver to unsnap the bracket from the rail.)

Direct Mounting

1. Choose an appropriate place to install the CIM300.

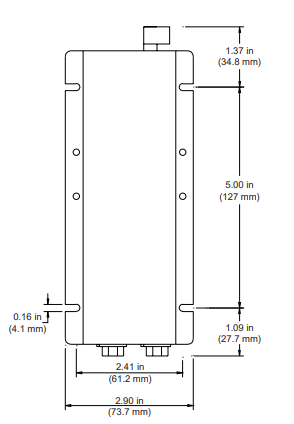

2. Use the dimensions shown in Figure 2.8 as a reference for

clearance and dimensions

Figure 2.8 CIM300 Template

3. Drill four holes for #6 or #8 screws in the chosen location.

4. Place the CIM300 where you will mount it. Use screws with

internal star lock washers to ensure a good frame ground

connection. You may use self-tapping screws. Insert the

screws through the standoffs and tighten them.

5. Be sure to remove any loose metal filings after you are

finished mounting the CIM300.

Do not connect power or sensors to the

MLS300 now. Test the unit first, as explained

in the Power Wiring and Controller Test section.

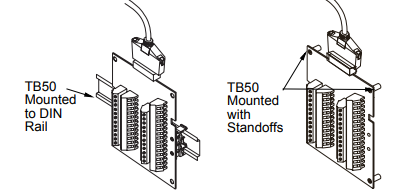

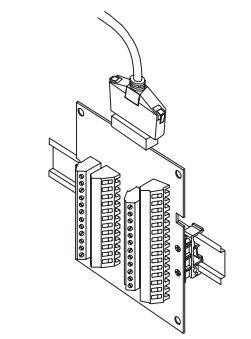

Mounting the TB50

There are two ways you can mount the TB50: use the preinstalled DIN rail mounting brackets provided or use the

plastic standoffs. Follow the corresponding procedures to

mount the board

DIN Rail Mounting

Snap the TB50 on to the DIN rail by placing the hook side on

the rail first, then pushing the snap latch side in place. Refer

to Figure 2.10.

Figure 2.10 TB50 Mounted on a DIN Rail (Front)

To remove the TB50 from the rail, use a flat-head screw driver

to unsnap the bracket from the rail. See Figure 2.11

Figure 2.11 TB50 Mounted on DIN Rail (Side)

Mounting with Standoffs

1. Remove the DIN rail mounting brackets from the TB50.

2. Select a location with enough clearance to remove the

TB50, its SCSI cable, and the controller itself.

3. Mark the four mounting holes.

4. Drill and tap the 4, #6 (3.5 mm) mounting holes.

5. Mount the TB50 with 4 screws.

There are four smaller holes on the terminal board. Use these

holes to secure wiring to the terminal block with tie wraps.

Figure 2.12 Mounting a TB50 with Standoffs

Mounting the Power Supply

If you use your own power supply for the MLS300, please

refer to the power supply manufacturer's instructions for

mounting information. Choose a power supply that supplies

an isolated regulated 12 to 24 Vdc at 1 A.

Mounting Environment

Leave enough clearance around the power supply so that it

can be removed.

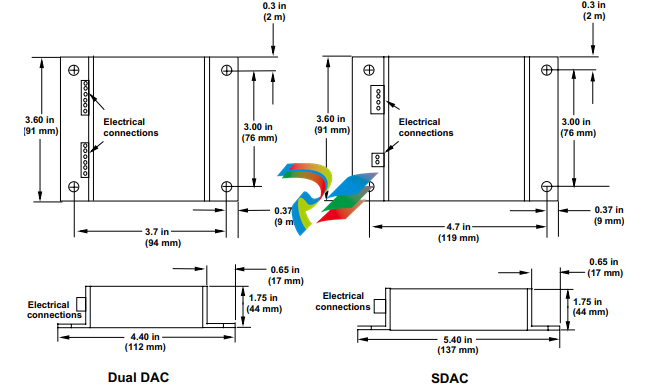

Mounting DAC or SDAC Module

This section describes how to install the optional DAC and

SDAC Digital-to-Analog Converters for use with a MLS300

series controller.

Installation

Installation of the DAC and SDAC is essentially the same.

The main differences are in the dimensions and the wiring.

Follow this procedure to correctly install these devices.

Jumpers

The output signal range of the DAC and SDAC modules is

configured with jumpers. See Configuring DAC Outputs on

page 210 and Configuring SDAC Outputs on page 212 for

information on setting these jumpers.

Mounting

1. Select a location for installation. The unit is designed for

wall mounting and should be installed as close to the controller as possible.

2. Mark and drill four holes for screw mounting. Holes

accommodate #6 size screws. Use the diagrams in Figure

2.14 on page 32 for the correct locations.

3. Install the unit with the four screws.

Figure 2.14 Dual DAC and SDAC Dimensions

System Wiring

Successful installation and operation of the control system can

depend on placement of the components and on selection of

the proper cables, sensors, and peripheral components.

Routing and shielding of sensor wires and proper grounding

of components can insure a robust control system. This

section includes wiring recommendations, instructions for

proper grounding and noise suppression, and considerations

for avoiding ground loops.