WATLOWMLS300 Series User’s Guide

or process values on power-up. Keep in mind that these

convenience features do not eliminate the need for

independent safety devices.

Contact Watlow Anafaze immediately if you have any

questions about system safety or system operation.

This chapter describes how to install the MLS300 series

controller and its peripherals. Installation of the controller

involves the following procedures:

• Determining the best location for the controller

• Mounting the controller, the AIM and the TB50

• Power connection

• Testing the system

• Input wiring

• Output wiring

• Communications wiring (EIA/TIA-232 or EIA/TIA485)

Typical Installation

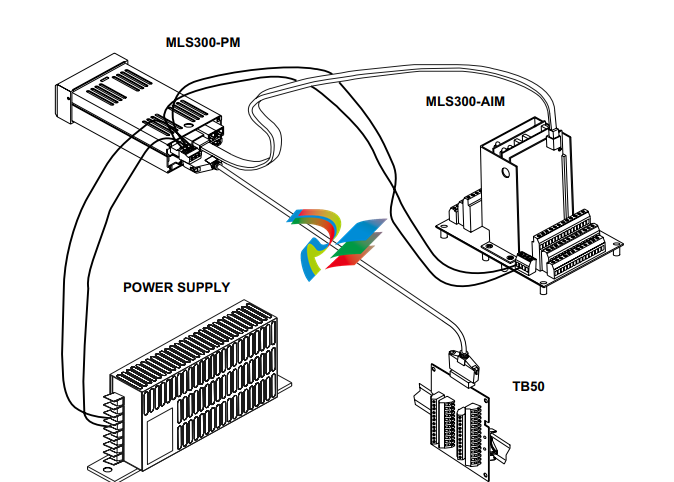

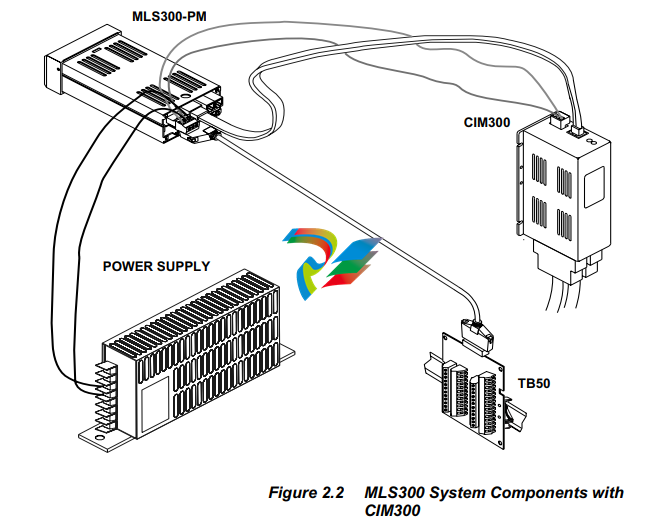

Figure 2.1 on page 18 illustrates a typical installation of the

MLS300-PM (controller) with the MLS300-AIM (analog

input module), TB50 terminal block, and power supply.

Refer to Figure 2.15 on page 36 for a more detailed view of

the power connections.

Read this entire chapter before beginning the installation

procedure.

Mounting Controller Components

Install the controller in a location free from excessive heat

(more than 50°C), dust and unauthorized handling.

Electromagnetic and radio frequency interference can induce

noise on sensor wiring. Select locations for the MLS300-PM

and MLS300-AIM and CIM300 such that wiring can be

routed clear of sources of interference such as high voltage

wires, power switching devices and motors

! The MLS300 system is for indoor use only. Install it in a controlled environment to reduce

the risk of fire or electric shock.

Recommended Tools

Use these tools to install the MLS300 series controller.

Panel Hole Cutters

Use any of the following tools to cut a hole of the appropriate

size in the panel.

• Jigsaw and metal file, for stainless steel and heavyweight

panel doors.

• Greenlee 1/8 DIN rectangular punch (Greenlee part #

600-68), for most panel materials and thicknesses.

• Nibbler and metal file, for aluminum and lightweight

panel doors.

Other Tools

You will also need these tools:

• Phillips head screwdriver

• Flathead screwdriver for wiring

• Multimeter

• A metal phone connector crimping tool (optional).

Watlow Anafaze provides all the cabling for the Modular

Loop System. If you have special cabling requirements and

you make your own RJ-12 communications cable, use a metal

crimping tool for the connectors. (A metal tool makes better

connections than a plastic tool.)

Mounting the Processor Module

Mount the processor module before you mount the terminal

block or do any wiring. The controller's placement affects

placement and wiring considerations for the other

components of your system.

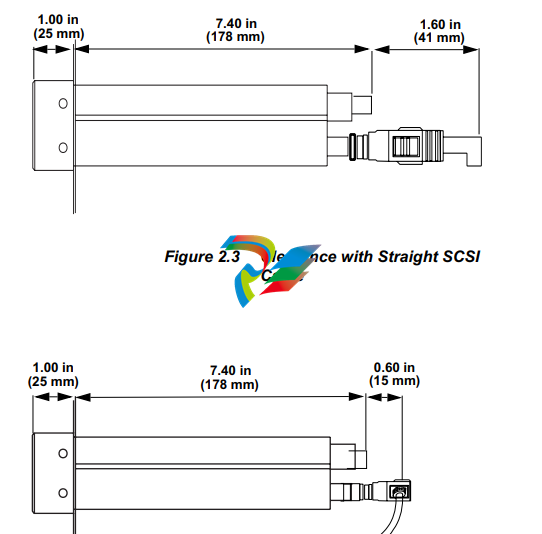

Ensure there is enough clearance for mounting brackets,

terminal blocks, and cable and wire connections; the

controller extends up to 9.0 in. (219 mm) behind the panel

face and the collar and brackets extend 9/32 in. (7 mm) on the

sides and 15/32 in. (12 mm) above and below it.

We recommend you mount the controller in a panel not more

than 0.2 in. (5 mm) thick.

1. Choose a panel location free from excessive heat (more

than 50°C), dust, and unauthorized handling. (Make sure

there is adequate clearance for the mounting hardware,

terminal blocks, and cables. The controller extends 7.40

in. (178 mm) behind the panel. Allow for an additional

0.60 to 1.60 in. (15 to 41 mm) beyond the connectors.

2. Temporarily cover any slots in the metal housing so that

dirt, metal filings, and pieces of wire do not enter the

housing and lodge in the electronics.

3. Cut a hole in the panel 1.80 in. (46 mm) by 3.63 in. (92

mm) as shown below. (This picture is NOT a template; it

is for illustration only.) Use caution; the dimensions given here have 0.02 in. (1 mm) tolerances.

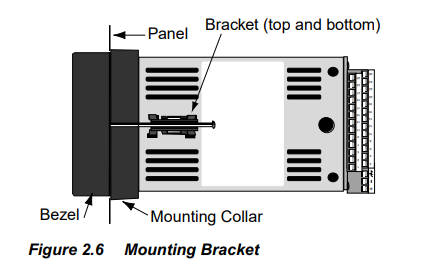

4. Remove the brackets and collar from the processor module, if they are already in place.

5. Slide the processor module into the panel cutout.

Slide the mounting collar over the back of the processor

module, making sure the mounting screw indentations

face toward the back of the processor module.

Loosen the mounting bracket screws enough to allow for

the mounting collar and panel thickness. Place each

mounting bracket into the mounting slots (head of the

screw facing the back of the processor module). Push

each bracket backward then to the side to secure it to the

processor module case.

Make sure the case is seated properly. Tighten the installation

screws firmly against the mounting collar to secure the unit.

Ensure that the end of the mounting screws fit into the

indentations on the mounting collar.

Mounting the MLS300-AIM

!

NOTE! If you plan to install scaling resistors, mount

them on the AIM-TB before mounting the

AIM-TB in the panel. See Chapter 9, Troubleshooting and Reconfiguring.

If you ordered an MLS300-AIM-TB with scaling inputs from Watlow Anafaze, the scaling

resistors are already installed.

Install the MLS300-AIM in a location free from excessive

(more than 50°C) heat, dust, and unauthorized handling.

The MLS300-AIM measures 6.5 L x 5 W x 7 in. H. Leave 6

in. of clearance above the MLS300-AIM, so you can remove