WATLOWMLS300 Series User’s Guide

controller from the front panel or from a local or remote

computer. WatView software is available to configure

and monitor the MLS300 from a PC.

• Modbus RTU Protocol, EIA/TIA-232 and 485

Communications: Connect to PLCs, operator interface

terminals and third-party software packages using the

widely supported Modbus RTU protocol.

• Multiple Job Storage: Store up to 8 jobs in memory, and

access them locally by entering a single job number or

remotely via digital inputs. Each job is a set of operating

conditions, including set points and alarms.

• Non-Linear Output Curves: Select either of two nonlinear output curves for each control output.

• Autotuning Makes Setup Simple: Use the Autotune

feature to set up your system quickly and easily. The

MLS300 internal expert system table finds the correct

PID parameters for your process.

• Pulse Counter Input: Use the pulse counter input for

precise control of motor or belt speed.

• Low Power Shutdown: The controller shuts down and

turns off all outputs when it detects the input voltage drop

below the minimum safe operating level.

MLS300 Series User’s Guide Chapter 1: System Overview

Doc.# 0600-3070-2000 Watlow Anafaze 5

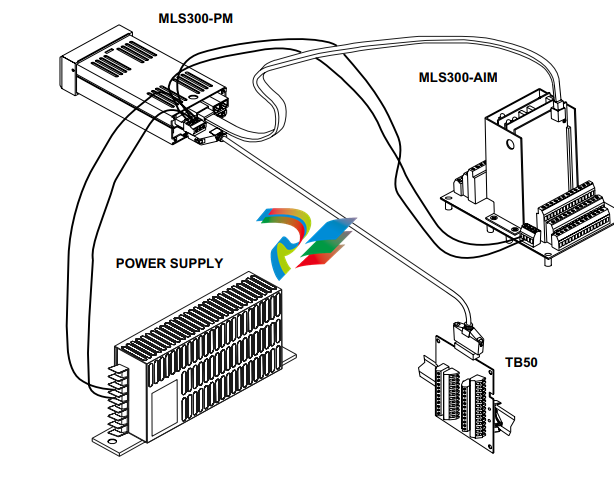

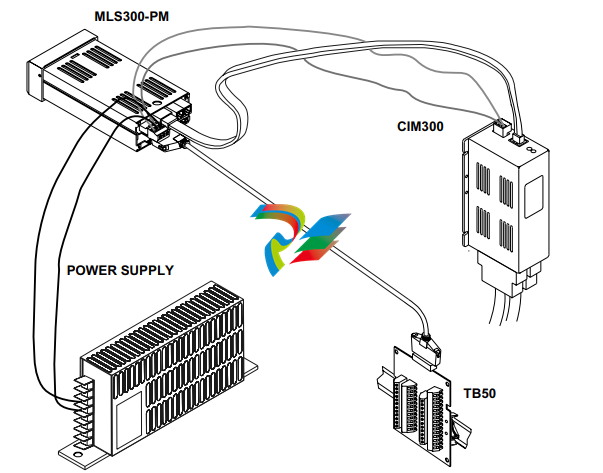

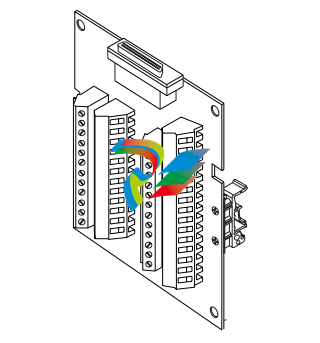

System Diagram

The illustration below shows how the parts of the MLS300 are

connected. When unpacking your system, use the diagram and

parts list below to ensure all parts have been shipped. Please

don't hesitate to call Watlow Anafaze's Customer Service

Department if you have problems with your shipment, or if the

MLS300's components are missing or damaged.

Parts List MLS316/MLS332

You may have received one or more of the following

components. Refer to Figure 1.1 on page 5 and Figure 1.2 on

page 6 for MLS300 configuration information.

• MLS300 Processor Module (PM)

• Controller Mounting Kit

• 16- or 32-Channel MLS300-AIM Module with 4-foot

AIM cable

• 16- or 32-Channel CIM300 Module with 4-foot AIM

cable.

• EIA/RS-232 or EIA/RS-485 Communication Cable

• TB50 with 50-pin SCSI Cable

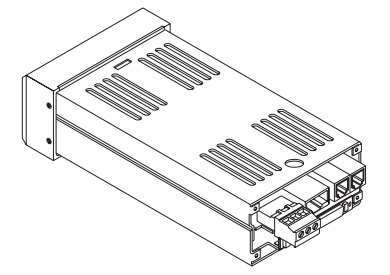

• Power Supply with Mounting Bracket and Screws

• SDAC (Serial Digital-to-Analog Converter)

• Special Input Resistors (installed in MLS300 AIM)

• User Manual

Technical Description

This section contains a technical description of each

component of your MLS300 Controller.

Processor Module

The MLS300 Processor Module (MLS300-PM) is housed in

an eighth-DIN panel mount package. It contains the CPU,

RAM with a built-in battery, EPROM, serial communications,

digital I/O, the screen and touch keypad.

The MLS300-PM has the following features:

• Keypad and 2-line, 16-character display.

• Screw terminals for the power inputs and outputs.

• Input power is 12 to 24 Vdc at 1 amp.

• The +5 Vdc output power supply of the processor module

powers the MLS300-AIM.

• The MLS300-PM interfaces with the MLS300-AIM with

an 8-pin RJ-45 style connector.

• A 50-pin SCSI cable connects the digital inputs and

outputs to the 50-pin terminal block (TB50).

• The MLS300 uses 6-pin, telephone-style connectors for

EIA/RS-232 and EIA/RS-485 external communications.

The program that operates the MLS300 is stored in a socketed,

flash, static-RAM chip, so it is easy to update or change the

firmware. The MLS300 stores its operating parameters in

battery-backed RAM, so if there's a power loss the operating

parameters are unchanged. The battery has a ten year shelf

life, and it is not used when the unit is on.

The microprocessor performs all calculations for input signal

linearization, PID control, alarms, and communications.

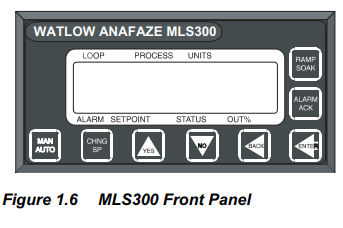

Front Panel Description

The MLS300-PM's display and touch keypad provide an

intelligent way to operate the MLS300. The display has 16

alphanumeric or graphic characters per line. The 8-key

keypad allows you to change the MLS300's operating

parameters, controller functions, and displays.

The MLS300's information-packed displays show process

variables, set points, and output levels for each loop. A bar

graph display, single loop display, scanning display and an

alarm display offer a real-time view of process conditions.

Two access levels allow operator changes and supervisor

changes.

The TB50 is a screw terminal interface for control wiring

which allows you to connect relays, encoders and discrete I/O

devices to the MLS300. The screw terminal blocks accept

wires as large as 18 AWG. A 50-pin SCSI cable connects the

TB50 to the MLS300-PM

MLS300-AIM and AIM-TB

The MLS300 Analog Input Module (MLS300-AIM), consists

of the AIM-TB (AIM Terminal Board) and the AIM’s plug-in

cards. The MLS300-AIM receives input signals from sensors

and transmits this information to the MLS300-PM through the

AIM cable.

The AIM-TB includes power supply terminals, input signal

wiring screw terminals, input signal conditioning circuits, and

terminal connections for the AIM's plug-in cards. It also

includes a cold junction temperature sensor and room for the