ABBDCS800 Quick guide DCS800 Drives (20 A to 5200 A)

ABB Drive Service EN

In order to offer the same after sales

service to our customer around the

world, ABB has created the DRIVE

SERVICE CONCEPT.

ABB's after sales service is globally

consistent due to common targets,

rules, and the way of operation. This

means for our customers:

Please visit the ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service FR

Pour offrir la même qualité de service

à tous nos clients, ABB a créé DRIVE

SERVICE CONCEPT.

Dans le monde entier, les équipes

de service proposent les mêmes

prestations aux mêmes conditions

avec les mêmes objectifs.

Pour en savoir plus, connectez-vous sur ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service DE

Um jedem Kunden rund um die

Welt die gleiche Service Dienstleistung anbieten zu können, hat ABB

das DRIVE SERVICE CONCEPT

entwickelt.

Durch die Definition von einheitlichen

Zielen, Regeln, und Arbeitsvorschriften kann ABB die Dienstleitungs

Produkte weltweit auf gleichwertig

hohem Qualitätsniveau anbieten. Für

unsere Kunden bedeuted dies:

Bitte besuchen Sie die ABBHomepage Service für Antriebe

www.abb.com/drivesservices

ABB Drive Service IT

ABB ha creato il DRIVE SERVICE

CENCEPT, con lo scopo di offrire ai

nostri clienti lo stesso servizio post

vendita in tutto il mondo.

Attraverso la definizione di obbiettivi

comuni, ruoli e modo di operare, le

attività post vendita di ABB offrono

sevizi coerenti nella loro globalità. Per

i nostri clienti questo significa:

Vi invitiamo a visitare la homepage

ABB drive service

www.abb.com/drivesservices

ABB Drive Service ES

Para poder ofrecer el mismo servicio posventa a nuestros clientes

en todo el mundo, ABB ha creado

el CONCEPTO DE SERVICIO DE

CONVERTIDORES.

El servicio posventa de ABB está

mundialmente consolidado gracias

a unos objetivos y normas comunes,

así como a su funcionamiento. Esto

significa para nuestros clientes:

Visiten el portal de convertidores

de ABB

Brief instructions for CD and documents overview

We appreciate that you purchased an ABB DC drive

power converter and thank you for the trust you put in our

products.

This brochure was put together to make sure that you continue

to be satisfied with our product. It is intended to provide you

with a brief overview of the product's key data, EMC notes,

typical applications, start-up and trouble-shooting.

If you need more information about the product you are

provided with a CD-ROM in addition to this brief documentation. The CD-ROM is part of this document and features

the following contents:

Documentation

Our documentation is basically structured according to the

following system:

Technical catalogue (3ADW000192)

as comprehensive information to engineer complete DC

drive systems.

Hardware manual (3ADW000194)

as detailed information, with all important particulars about

the individual components, like module dimensions, electronic

boards, fans and auxiliary components.

Information for mechanical and electrical installation are

also included.

Firmware Manual (3ADW000193)

detailed information with all important issues about firmware

and setting of parameters. The manual includes information

for start-up and maintenance of the entire drive, in detailed

form.

This manual also includes Fault and Alarm codes and information for trouble shooting.

Service Manual (3ADW000195)

for maintenance and repair of the converters.

Applications

DCS800 DC Drive can include application software e.g.

cranes, winders. In such case following procedures and

assistants can be blocked or not completed. Please check

for further documentation and manuals (check parameter

4.03, 83.01).

Additional information about applications (e.g. 12-pulse)

and technical accessories (e.g. Hardware extension or

Field bus interfaces) are handled by separate manuals. See

table DCS800 Drive manuals.

System requirements to use the CD-ROM

• Operating system WINDOWS 2000, XP

• ACROBAT READER 4.0 is

sufficient (we recommend

8.0 - included on the CDROM)

In case the CD ROM does not start automatically please

double-click on Setup.exe.

Further support

In addition we offer further support, since we can only be

satisfied when you, as our customer, are satisfied with us

and our products.

Internet

On the ABB homepage under

www.abb.com/dc

you'll find abundant information for

• DC products

• service support

• the latest updates

• tools

• downloads, etc.

Please don't hesitate to visit us.

Contacts

If you require any further information, please contact your

nearest ABB Drives office or send an email to:

DC-Drives@de.abb.com

Please give us your name, your company address and

phone number. We immediately put you in contact with our

specialist.

Notes on EMC

You will find further information in publication:

Technical Guide chapter:

EMC Compliant Installation and Configuration for

a Power Drive System

The paragraphs below describe selection of

the electrical components in conformity with

the EMC Guideline.

The aim of the EMC Guideline is, as the name

implies, to achieve electromagnetic compatibility with other products and systems. The

guideline ensures that the emissions from

the product concerned are so low that they

do not impair another product‘s interference

immunity.

In the context of the EMC Guideline, two

aspects must be borne in mind:

• the product‘s interference immunity

• the product‘s actual emissions

The EMC Guideline expects EMC to be taken

into account when a product is being developed;

however, EMC cannot be designed in, it can only

be quantitatively measured.

Note on EMC conformity

The conformity procedure is the responsibility of

both the power converter‘s supplier and the manufacturer of the machine or system concerned, in

proportion to their share in expanding the electrical

equipment involved.

For compliance with the protection objectives

of the German EMC Act (EMVG) in systems and

machines, the following EMC standards must

be satisfied:

Product Standard EN 61800-3

EMC standard for drive systems (PowerDriveSystem), interference immunity and emissions

in residential areas, enterprise zones with light

industry and in industrial facilities.

This standard must be complied with in the EU

for satisfying the EMC requirements for systems

and machines!

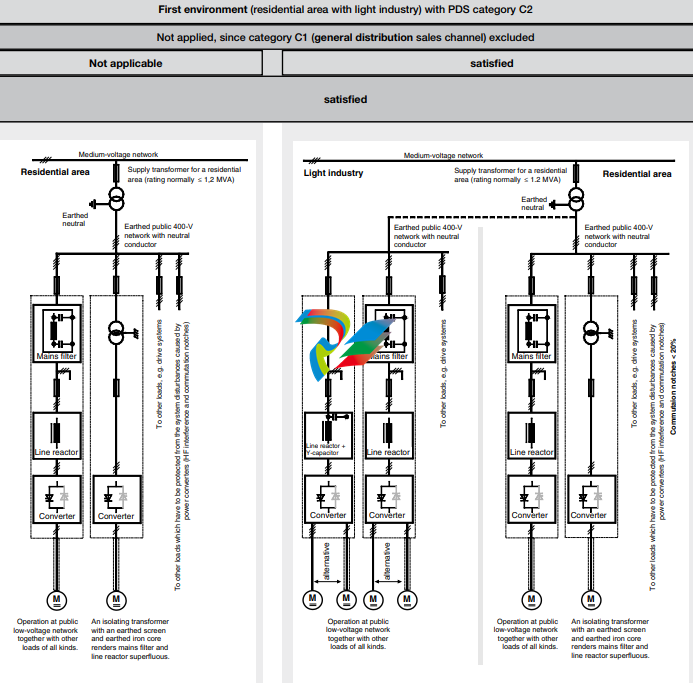

Classification

The following overview utilises the

terminology and indicates the action required in accordance with

Product Standard

EN 61800-3

For the DCS800 series, the limit

values for emitted interference

are complied with, provided the

measure indicated is carried

out. PDS of category C2 (formerly restricted distribution in

first environment) is intended to

be installed and commissioned

only by a professional (person

or organization with necessary

skills in installing and/or commissioning PDS including their

EMC aspects).

For power converters without

additional components, the following warning applies:

This is a product of category C2

under IEC 61800-3:2004. In a

domestic/residential environment

this product may cause radio

interference in which case supplementary mitigation measures

my be required.

The field supply is not depicted

in this overview diagram. For the

field current cables, the same

rules apply as for the armaturecircuit cables.

M M M M

emv_clssif_b.dsf

Converter

transformer

Case-referenced EMC analysis

alternative

Converter

transformer

with earthed

iron core

(and earthed

screen where

appropriate)

alternative

I > 400 A

and/or

U > 500 V

Operation with separate power converter transformer. If there

are other loads at the same secondary winding, these must be

able to cope with the commutation gaps caused by the power

converter. In some cases, commutating reactors will be

required.

To other loads, e.g. drive systems

Converter Converter

Line reactor

Medium-voltage network

Industrial

zone

For emitted interference, the following apply:

EN 61000-6-3 Specialised basic standard for emissions in light industry

can be satisfied with special features (mains filters, screened

power cables) in the lower rating range *(EN 50081-1).

EN 61000-6-4 Specialised basic standard for emissions in industry

*(EN 50081-2)

For interference immunity, the following apply:

EN 61000-6-1 Specialised basic standard for interference immunity in

residential areas *(EN 50082-1)

EN 61000-6-2 Specialised basic standard for interference immunity in industry. If this standard is satisfied, then the EN 61000-6-1

standard is automatically satisfied as well *(EN 50082-2).

* The generic standards are given in brackets

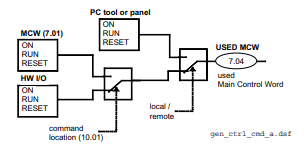

START, STOP and E-STOP control

The relay logic can be split into three parts:

a: Generation of the ON/OFF and START/STOP command:

The commands represented by K20 and K21 (latching interface relay) can be e.g. generated by a PLC and transferred to

the terminals of the converter either by relays, using galvanic

isolation or directly via 24V signals.

These commands can be as well transferred via serial

communication. Even a mixed solution can be realized by

selecting different possibilities for the one or the other signal

(see parameter group 11).

b: Generation of control and monitoring signals:

The main contactor K1 for the armature circuit is controlled

by a dry contact (DO 8) located on the SDCS-PIN-4. Status

of fans and fans klixon can be monitored by means of fan

ack signals: MotFanAck (10.06) and ConvFanAck (10.20).

c: OFF2, OFF3 Stop function:

Beside ON/OFF and START/STOP, the drive is equipped

with two additional stop functions, OFF2 and OFF3, according to Profibus standard. OFF3 is a scalable stop function

(rampstop, max torque stop, dynamic braking …) to perform

stop category 1. This function should be connected to the

E-STOP button without any time delay. In case of ramp stop

selection the, K 15 timer relay must be set longer than the

EStopRamp (22.04). For COAST selection, the drive opens

the main contactor immediately.

OFF2 switches off DC current as fast as possible and prepares the drive for opening main contactor or drop down

mains supply. For a normal DC motor load the time to switch

OFF the DC current is below 20 ms. This function should be

connected to all signals and safety functions opening the main

contactor. This function is important for 4-quadrant drives.

Do not open main contactor during regenerative current.

The correct sequence is

1. switch off regenerative current

2. then open the main contactor

In case of the E-STOP is hit, the information is transferred

to the converter via digital input 5. In case of rampstop, or

max torque selection the converter will decelerate the motor

and then open main contactor.

If the drive has not finished the function within the K15 timer

setting, the drive must get the command to switch OFF the

current via K16. After K16 timer set has elapsed the main

contactor is opened independent of the drives status.

Notes For North American Installations

1. EMC conformity is not usually required in North America. In most cases, the section “Notes on EMC” can be

bypassed. In this manual, you will see references to DIN, EN

and VDE standards. These are European standards and,

generally, do not apply to North America. It is, however,

the responsibility of the user to determine which standards

need to be followed.

2. If using a DC contactor, you must connect an auxiliary

contact to a digital input of your choice and set para. MainContAck accordingly. Set the following parameters:

MainContAck (10.21) = DI-1 (or any input you

choose for the DC cont.

auxiliary contact)

DO8BitNo (14.16) = 10

MainContCtrlMode (21.16) = DCcontact (3)

Set these parameters AFTER macros are loaded but BEFORE

the drive is commissioned.

Digital output 8 (DO-8) must be used to turn the DC

contactor on and off.

3. If using Dynamic Braking, the drive allows you to select the stopping method under three different situations.

Parameters 21.02, 21.03 and 21.04 select the stopping

method for loss of

the OnOff, run command (StartStop, Jog1, Jog2, etc.), and

E-Stop input, respectively.

Each can be set to:

• RampStop • TorqueLimit

• CoastStop • DynBraking

In order to command the drive to perform a DB stop, one

or more of these parameters must be set to DynBraking.

Most users will want the drive to ramp stop when OnOff or a

run command (StartStop, Jog1, Jog2, etc.) input is cleared,

and dynamically brake when the E-Stop input is cleared. In

that case, use the following settings:

• Off1Mode (21.02) = RampStop

• StopMode (21.03) = RampStop

• E StopMode (21.04) = DynBraking

However, any case is allowed and the final decision is left

to the user.

Other parameters control stops during faults.

See:

LocalLossCtrl (30.27) ComLossCtrl (30.28)

FaultStopMode (30.30) SpeedFbFltMode (30.36)

If using EMF feedback with dynamic braking, set:

• DynBrakeDly (50.11) = t

Where: t = the time (sec) it normally takes the motor

to stop during dynamic braking

DC contactor US:

DC contactor US K1.1 is a special designed contactor with 2x

NO contacts for C1 and D1 connection and 1x NC contact for

connection of Dynamic Brake resistor RB.

The contactor should be controlled by signal 6.03 Bit 10.

The acknowledge can be connected to parameter:

10.21 MainContAck

10.23 DCBreakAck

Overview of the Installation and Commissioning Process

This is to protect the motor and converter if a commutation

fault should occur. NOTE: DC output fuses are the same

type and size as AC line fuses.

Line reactor:

All thyristor-based dc converters cause notching in the AC

line due to motor commutation. A properly sized line reactor

will mitigate the effect on the line. Unless the converter uses

a dedicated isolation transformer, each converter requires

its own line reactor.

AC or DC contactor:

A contactor is required to safely disconnect the motor from

the incoming power when the converter is off. The contactor

can be installed between the line and the converter (an AC

contactor) or between the converter and the motor (a DC

contactor). Do not use both.

IMPORTANT: Other equipment may be necessary depending on application and local codes.

Step 1:

Check converter for damage. Contact ABB Technical Support

if damage is found. In North America, call 1-800-435-7365

(1-800-HELP-365)

Step 2:

Select supporting hardware for the converter:

For specific recommendations for fuses, reactors, and

contactors, see the DCS800 hardware manual or technical

catalog.

Circuit breaker or disconnect:

Current rating = Idc * 0.816 * 1.25 (min)

= Idc * 0.816 * 2.50 (max)

Where: Idc = nominal DC motor current

Fuses:

AC Line Fuses: To properly protect the converter, semiconductor fuses on the incoming AC power line are required

in all cases.

DC Output Fuses: Fuses between the motor and the

converter are required for all regenerative (4-Q) converters.

Step 3:

Mount and wire the converter and supporting hardware inside an industrial enclosure with adequate cooling (DCS800

modules have rating of NEMA type OPEN).

The following control and signal wiring is required:

o If using an AC contactor, we recommend wiring an auxiliary contact to the digital input you have designated as

MainContAck (10.21) or Start/Stop (10.16).

o If using a DC contactor, you must wire an auxiliary contact

from the contactor to the digital input you have designated

as MainContAck (10.21).

o Wire 115 or 230 Vac 1-phase power to terminal block 99

for converter control power.

o Wire 1-phase power to converter for cooling fans. See

table and wiring diagrams in this manual.

• D1 – D3 frames: 115/230 Vac selectable. Fan

terminal X2 is on top of the converter.

• D4 frame: If type code includes +S171, use 115

Vac; otherwise use 230 Vac. Fan terminal X2 is

on top of the converter.

o Wire tachometer or encoder to terminal block X3 (tacho)

or X5 (encoder).

o Wire analog inputs (e.g., speed reference) and outputs

(e.g., meters for motor voltage, current) to terminal block

X3 and/or X4.

o Wire high speed serial interface if needed. (Requires

optional fieldbus interface board.)

o The DCS800 allows you to choose the usage of each

digital and analog input and output. The converter has

factory default settings which can be changed by loading

a macro, but some designations are universal. They

include:

• Digital input 5: Estop

• Digital input 6: Fault reset

• Digital input 7: On/Off (maintained) or On-Start

(pulsed)

• *Digital input 8: Start/Stop (maintained) or OffStop (pulsed)

• Digital output 8: Main Contactor On (3 Amps

max. at 115 – 230 Vac)

*except Hand/Auto macro

o Other signals may be required depending on your application (e.g., motor fan acknowledge input, Off2 input,

fan-on output, brake output).

o You will select the macro and / or choose the configuration

for digital and analog inputs and outputs in step 2 of the

commissioning process, or by updating group 10 and 14

parameters.

o Check all wire terminations (with continuity tester) before

proceeding to the next step.

Step 4:

Connect the drive system to incoming power and the motor to

the converter (both field and armature) as well as accessory

equipment (motor fan, thermal switch, brake, etc.).

o See hardware manual for typical cable size and tightening

torque recommendations.

o IMPORTANT: Be sure all safety equipmentis properly

sized for your application

Step 5:

Apply control power to the converter.

o IMPORTANT: See section “Safety and Operating

Instructions” in this manual before proceeding.

o Apply power to terminal block 99 and X2. The keypad

should light up and show the menu screen. The converter

fans should start to run (if converter has fans).

Step 6:

Commission the converter using Drive Windows Light

(preferred) or the control panel.

o IMPORTANT: Seesafetyalertsandgeneralinstructions

in the section “Commissioning” before proceeding.

o Install the DCS800 PC tools on your computer. Instructions

are in this manual. Use DriveWindow Light to commission

your converter.

o If no PC is available, commission your drive using the

control panel as follows:

• On the control panel, press the softkey to select

MENU.

• Using the down arrow, select ASSISTANTS. Then

press ENTER.

• Starting with “name plate data,” press SEL.

Change the value with the arrow keys. Then press

SAVE.

• Repeat above with other parameters. Follow

directions on the screen.

Configuring and Displaying analog and digital I/O

HINT: To see if the drive is responding to an “on” or “run” command, view signal 8.08.

Control Panel:

o Digital Status: View signal 8.05 (DI’s) or 8.06 (DO’s).

Display is in hexadecimal.

o Configure digital inputs with Group 10.

o Analog Status: View signal 5.03 (AI1) or 5.11 (AO1).

Display is in Volts.

o Configure analog speed ref. with Group 11.

DriveWindow Light:

o Connect to the DCS800 and go on line by clicking on

File, then New Online Drive.

o Click on Wizard, at left side of the screen.

o Click on Advanced.

o Check the box for “I/O assistant,” then click on Next.

o Click on “edit parameters” in the appropriate section

(analog or digital inputs or outputs).

Safety and operating instructions

for drive converters DCS / DCF / DCR

1. General

In operation, drive converters, depending on their degree of

protection, may have live, uninsulated, and possibly also moving

or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of

improper use, wrong installation or maloperation, there is the

danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning

as well as maintenance are to be carried out by skilled technical personnel (Observe IEC 364 or CENELEC HD 384 or DIN

VDE 0100 and IEC 664 or DIN/VDE 0110 and national accident

prevention rules!).

For the purposes of these basic safety instructions, “skilled

technical personnel” means persons who are familiar with the

installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance

of their functions.

2. Intended use

Drive converters are components designed for inclusion in electrical installations or machinery.

In case of installation in machinery, commissioning of the drive

converter (i.e. the starting of normal operation) is prohibited until

the machinery has been proved to conform to the provisions of

the directive 89/392/EEC (Machinery Safety Directive - MSD).

Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal opertion) is admissible

only where conformity with the EMC directive (89/336/EEC) has

been established.

The drive converters meet the requirements of the low-voltage

directive 73/23/EEC. They are subject to the harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with

EN 60439-1/ VDE 0660, part 500, and EN 60146/ VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate and from the

documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be

complied with.

The climatic conditions shall be in conformity with prEN 50178.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent documentation.

The drive converters shall be protected against excessive

strains. In particular, no components must be bent or isolating

distances altered in the course of transportation or handling. No

contact shall be made with electronic components and contacts.

Drive converters contain electrostatic sensitive components

which are liable to damage through improper use. Electric

components must not be mechanically damaged or destroyed

(potential health risks).

5. Electrical connection

When working on live drive converters, the applicable national

accident prevention rules (e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance with

the relevant requirements (e.g. cross-sectional areas of conductors, fusing, PE connection). For further information, see documentation.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters and wiring,

are contained in the drive converter documentation. They must

always be complied with, also for drive converters bearing a

CE marking. Observance of the limit values required by EMC

law is the responsibility of the manufacturer of the installation or

machine.

6. Operation

Installations which include drive converters shall be equipped

with additional control and protective devices in accordance with

the relevant applicable safety requirements, e.g. Act respecting

technical equipment, accident prevention rules etc. Changes

to the drive converters by means of the operating software are

admissible.

After disconnection of the drive converter from the voltage

supply, live appliance parts and power terminals must not be

touched immediately because of possibly energized capacitors.

In this respect, the corresponding signs and markings on the

drive converter must be respected.

During operation, all covers and doors shall be kept closed.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

Keep safety instructions in a safe place!

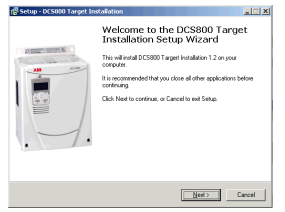

Installing the DCS800 PC tools on Your computer

After inserting the DCS800 CD all programs and documentation

necessary to work with the DCS800 will be automatically installed.

This includes:

1. DriveWindow Light for parameterization, commissioning and

service

2. Hitachi FDT 2.2 for firmware download

3. Installation CD of DCS800 Drive for e.g. DWL Wizard, ABB

documents

4. CoDeSys for 61131 application programming

Attention:

If You do not want to install a certain program just skip it by using

Cancel at the beginning of the program’s wizar

If the installation routine does not start automatically:

- Go to Start/Run and browse for setup.exe on the CD. Now start

the installation by confirming with OK

- Compact installtion for DriveWindow Light + Commsioning

Wizard + DriveWindow Light AP is reccomended

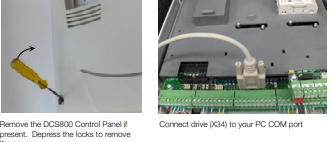

Steps to connect Drive to PC

• The documentation can be found under

C:ABBDCS800Docu

• Remove design cover from the converter module

• Start DriveWindow Light PC tool

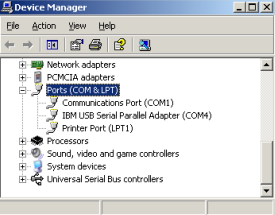

Check the communication setting of your COM port

If You use USB to COM port interface or PCMCIA / COM adapters double check the active COM enabled

Start => Settings => Control Panel => System => Hardware

=> Device Manager

COM address of USB interface can change after the next boot

procedure or after disconnecting and reconnecting of the USB

interface.

Note:

PCMCIA to COM Port provide a stable and faster drive interface.

Utilize DriveWindow Light or DCS800 Panel Wizard continue

with chapter Commissioning in this manual.

For commissioning by DriveWindow find a workspace description in the DCS800 Firmware manual.

Danger! High voltage: this symbol warns of high

voltages which may result in injuries to persons

and/or damage to equipment. Where appropriate,

the text printed adjacent to this symbol describes

how risk of this kind may be avoided.

General warning: this symbol warns of non-electrical risks and dangers which may result in serious

or even fatal injuries to persons and/or damage to

equipment. Where appropriate, the text printed

adjacent to this symbol describes how risk of this

kind may be avoided.

General instructions

• This short commissioning refers to Chapter 5 Connection examples of this publication.

• Safety and operating instructions - see chapter 6

of this publication.

• Recommendations for motor and field voltages see

Technical catalogue.

• In accordance with DIN 57 100 Part 727 / VDE 0100

Part 727, precautions must be taken to enable the

drive to be shut down, e.g. in the event of danger.

The unit’s digital inputs or the control panel are not

sufficient as the sole measure for this purpose!

Warning of electrostatic discharge: this symbol

warns you against electrostatic discharges which

may damage to unit. Where appropriate, the text

printed adjacent to this symbol describes how risk

of this kind may be avoided.

NEC motor overload protection

The DCS800 provides a solid-state motor overload

protection in accordance with the NEC. The overload

protection (e.g. protection level in percent of full-load

motor current) can be adjusted by parameters in

group 31 and group 99.

The instructions can be found in chapter Motor

thermal model of the DCS800 Firmware manual.

Preparations

• Check unit for any damage!

• Install unit and wire it up

• Supply voltage level / Rated value correct for electronics and fan?

• Supply voltage level / Rated value correct for armature-circuit converter?

• Supply voltage level / Rated value correct for field

supply?

• Wiring / cross-sections, etc. correct?

• EMERGENCY STOP functioning properly?

• COAST STOP functioning properly?

Standard Features

• kompakt

• Höchste Leistungsfähigkeit

• Einfachste Bedienung

• Komfortable Assistenten, z. B. zur Inbetriebnahme

oder Fehlersuche

• Skalierbar für alle Anwendungen

• Frei programmierbar dank eingebauter IEC61131-SPS

DCS800 Gleichstromantriebe

Technische Daten DCS800

Nennanschlusssp. 230 bis 1.200 V

+/–10%, 3~

Frequenz 50 bis 60 Hz +/–5 Hz

Elektronikspg. 115 bis 230 V

–15% / +10%, 1~

DC Ausgangsstrom 20 bis 5.200 A

Überlastbarkeit 200%

Umgebungsgrenzwerte

Umgebungstemp. 0° bis +40° C

40°bis 55°C

Stromreduktion

Lagertemperatur –40° bis +55° C

Transporttemp. –40° bis +70° C

Relative 5 bis 95%, nicht

Luftfeuchtigkeit kondensierend

max. 50% zw. 0° und

5° C

Verschmutzungsgrad Klasse 2

Schutzgrad IP 00

Betriebshöhe bis 1.000 m üNN

Nennstrom

Über 1.000 m üNN

Stromreduktion

Ein-/ Ausgänge

Digitale Eingänge 8 Standard,

bis 14 optional

Digitale Ausgänge 8 Standard,

bis 12 optional

Analoge Eingänge 4 Standard

+/–10 V; 0/2…10 V bis 8 optional

+/–2 0mA; 0/4…20 mA

Analoge Ausgänge 3 Standard

(1x Iist) +/-10 V; 0/2…10 V bis 7

optional –20 mA; 0/4…20 mA

PC-Tools

DriveWindow Light

kostenlos mit jedem Antrieb,

Standard RS232 Verbindung

DriveWindow Echtzeit optische

Verbindung

ControlBuilder DCS800

IEC61131 Programmierung

DriveSize Antriebs- und

Motorauslegung

Wartung / Diagnose

Fernwartung von jedem InternetPC aus

• mit Internet Browser / Internet

Explorer

• oder mit DriveWindow Vollzugriff

via OPC

Zulassungen

Adaptive Programmierung

fertige antriebsspezifische

Blöcke, darunter

• Freier Prozessregler (PI-Regler)

• Ein/Ausgänge

Mit Bedien-Panel oder PC-Tool,

ohne zusätzliche Hardware

Drehzahlrückführung

EMK

Analoger Tachometer

Inkrementalgeber

Zweiter Inkrementalgeber möglich

(RTAC)

Kommunikation

Verfügbare serielle Schnittstellen

• Ethernet • Profibus

• CANopen • DeviceNet

• ControlNet • DDCS

• Modbus

• CS31 • AF100

• Selma2

Industrial IT© enabled

DCSLink Peer-to-Peer

• bis 800 kBaud, < 2,5 ms

• Master-Follower

• Anker-Feldstromrichter

• frei definierbare Daten

Hochstromlösungen

• 12-puls bis 20.000 A, seriell und

parallel

• Hart parallel und sequenziell

• bis 1.500 V

Schutzfunktionen

Tachosignalüberwachung • Temperatur • Überlast • Überdrehzahl

• Motor blockiert • Motorüberstrom • Motorüberspannung •

Feldüberstrom • Feldüberspannung • Mindestfeldstrom • Drehzahl Null • Ankerstromwelligkeit •

Netz Über- und Unterspannung

Integrierte IEC 61131-SPS

• Offenes Programmiertool

ControlBuilder DCS800

• Unterstützung aller fünf IECSprachen

• Antriebsspezifische

Funktionsblöcke

• Speicherung in Memory Karte

• Online Debugging und Forcing

Kurzanweisung CD und Dokumentationsübersicht

Wir freuen uns, dass Sie einen ABB DC-Stromrichter erworben haben und bedanken uns für das Vertrauen, welches

Sie unseren Produkten entgegengebracht haben.

Damit Sie auch weiterhin mit unserem Produkt zufrieden sind,

haben wir diese Broschüre für Sie zusammengestellt. Sie

soll hauptsächlich dazu dienen, ihnen einen kurzen Überblick

über das Produkt, EMV Hinweise, typische Anwendungen,

Inbetriebnahme und Fehlersuche zu verschaffen.

Benötigen Sie weitere Informationen zum Produkt, wurde

zusätzlich mit dieser Broschüre eine CD-ROM geliefert.

Die CD-ROM ist Teil dieser Broschüre und hat folgende

Bestandteile:

Dokumentation

Unsere Dokumentation ist folgendermaßen aufgebaut:

Technischer Katalog (3ADW000192)

als umfassende Information zur Planung kompletter DCStromrichter.

Hardware Handbuch (3ADW000194)

als Detailinformation mit allen wichtigen Angaben zu

den Einzelkomponenten, wie z.B. Modulabmaße, Elektronikkarten, Lüfter und Zusatzkomponenten.

Informationen über die mechanische- und elektrisch Installation sind auch enthalten.

Firmware Handbuch (3ADW000193)

Detailinformation mit allen wichtigen Angaben zur Firmware

und Einstellungen der Parameter. Dieses Handbuch enthält

mit allen notwendigen Informationen zur Inbetriebnahme.

Außerdem sind sowohl alle Fehler- und Alarmmeldungen

aufgelistet als auch Informationen zur Fehlersuche.

Service Manual (3ADW000195)

für die Wartung und Reparatur der Stromrichter.

Applikationen

Der DCS800 DC-Stromrichter kann auch Applikationsprogramme enthalten z.B. für Kräne und Wickler. In solchen Fällen

ist es möglich, daß die folgenden Anweisungen oder diverse

Assistenten entweder gesperrt sind oder nicht beendet werden können. Bitte mit Hilfe weiterführender Dokumentation

überprüfen (siehe auch Parameter 4.03 und 83.01).

Weitere Informationen über Applikationen (z.B. 12-Puls)

und technisches Zubehör (z.B. Hardwareerweiterungen oder

Feldbusadapter) werden in separaten Handbüchern behandelt. Siehe Tabelle DCS800 Antrieb Handbücher.

Systemvoraussetzungen für die Nutzung

der CD ROM

• Betriebssystem WINDOWS

2000, XP

• ACROBAT READER 4.0

ist ausreichend (empfohlen

wird 8.0 - auf der CD ROM

enthalten)

In case the CD ROM does not start automatically please

double-click on Setup.exe.

Weitere Unterstützung

Wir bieten Ihnen darüber hinaus weitere Unterstützung an,

denn nur wenn Sie als Kunde mit uns und unseren Produkten

zufrieden sind, können auch wir zufrieden sein.

Internet

Auf der ABB Homepage unter

www.abb.com/dc

finden Sie viele Informationen zu

• DC Produkten

• Service

• neueste Updates

• Anwendersoftware

• Downloads etc.

Bitte zögern Sie nicht uns dort zu besuchen.

Kontakte

Benötigen Sie weitere Informationen, sprechen Sie bitte Ihr

nächstgelegenes ABB Drives Büro an oder schreiben Sie

eine E-Mail an:

DC-Drives@de.abb.com

Geben Sie bitte Ihren Namen, Ihre Firmenadresse und Telefonnummer an und wir werden Ihnen umgehend den für

Sie zuständigen Ansprechpartner mitteilen.