EMERSONTest Platform for Automation System

Abstract

There are different automation systems to control processes in industry. One of them is

DeltaV, which is a product from Emerson Process Management. Recently, Sandvik

Coromant, bought the DeltaV automation system for using it in production. To increase

the knowledge about DeltaV at Sandvik Coromant a project was initiated with the aim to

create a test platform and a course compendium for self learning. This thesis describes

how the test platform was developed and its functionality

Testplattform för styrsystemet DeltaV

Examensarbete vid Skolan för Elektro- och Systemteknik

Sammanfattning

För att styra processer i industrin finns det olika styrsystem. Ett av dessa är DeltaV, som

är en produkt från Emerson Process Management. Nyligen köpte Sandvik Coromant

styrsystemet DeltaV för att använda det i sin produktion. För att öka kunskapen om

DeltaV på Sandvik Coromant initierades ett projekt: Att utforma en test plattform och ett

kurskompendium för självlärning. Denna uppsats beskriver hur tesplattformen har

utvecklats och dess funktionalitet.

Foreword

This report presents a Master’s project at the School of Electrical Engineering at the

Royal Institute of Technology (KTH) in Stockholm, Sweden.

The project has been performed at Sandvik Coromant in Västberga, Sweden. I want to

thank Sandvik Coromant for accepting me and Stefan Hedberg and Patrik Schütt for

their support throughout the project. I would also like to thank my supervisor, Professor

Håkan Hjalmarsson, at the School of Electrical Engineering, KTH, for his support.

I have performed this project in collaboration with Daniel Engdahl, who also is a member

of this project

Chapter 1

Introduction

Sandvik Coromant is the world's leading manufacturer of cutting tools for the

metalworking industry. Advanced production processes require advanced automation

systems for the control.

Production processes normally consist of a number of devices like valves, engines,

sensors, transmitters and controllers. These devices are controlled and monitored from

an automation system.

Sandvik Coromant has recently bought a new automation system, DeltaV, which is a

product from Emerson Process Management. To increase the knowledge about the

automation system at Sandvik Coromant, a project was initiated with the aim to create a

test platform and a course compendium for self learning.

This chapter describes the problem to be solved, the background to the automation

system DeltaV and gives the outline for the rest of the report.

1.1 Problem

In the following subsections the problem is described.

1.1.1 Task

The task in this project was to create a portable test platform for an educational purpose

for one of the automation systems, DeltaV from Emerson Process Management, that is

used at Sandvik Coromant. Along with the test platform, there should also be a course

compendium that describes how to learn DeltaV by using the test platform. The test

platform and the course compendium should together work as selflearning tools for the

personell at Sandvik Coromant. The platform should be small enough to be portable, so

that it can be brought to people who needs to learn DeltaV, independently of where they

are stationed.

Since the purpose of the task was not to learn how the production processes work, there

was not any requirement that the test platform should be similar to any process where

DeltaV is used at Sandvik Coromant. The only required similarity between the test

platform and the production processes at Sandvik Coromant was supposed to be that

similar measurement equipment was used.

1.1.2 Purpose

The DeltaV automation system has been used at Sandvik Coromant for two years. The

purpose of creating a test platform was to increase the knowledge of the automation

system among the personnel.

Since production processes are in general very costly to interrupt, a test platform was

needed to experiment with the functions of DeltaV. With the test platform the personnel

at Sandvik Coromant should be able to learn more about the automation system on their

own by testing how to control a physical process. The test platform along with the course

compendium should work as a selflearning tool.

1.1.3 Previous work

This is the first test platform and also the first course for DeltaV that has been developed

at Sandvik Coromant. The manufacturer of DeltaV, Emerson Process Management,

provides DeltaV courses. However, these courses do not come with a portable test

platform.

1.1.4 Description of the problem

The desire from Sandvik Coromant was to have a physical process, a software with

control algorithms for controlling the physical process and a course compendium on how

to learn DeltaV.

The requirement on the hardware in the physical process was that it should at least

include basically the same equipment as the production processes that are controlled

with DeltaV; relays, fuses, pressure transmitter, proximity sensors etc. Naturally, the

hardware should also include the automation system, DeltaV. The platform should be

small enough to be portable.

The requirement on the software part was similarly that it should at least include some

similar algorithms as the software for the real production processes includes. It was also

required that the software should include an operator interface in which an operator can

get the relevant information about the process; alarms indicating that something is

wrong, diagrams, an illustration of the process where the operator can follow what

happens etc.

The requirement on the course compendium was that a person who reads it should be

able to replicate the control software that was developed in this project. Persons taking

the course will have the original software as a key, which they should only use if they

experience significant problems.

Hence, to meet all requirement from Sandvik Coromant, the finished platform and

additional educational material should include the following:

• The DeltaV System with controller cards, I/O cards and fieldbus cards.

• Devices that are more or less the same as in the production processes at

Sandvik Coromant where DeltaV is used, for instance proximity sensors or

pressure transmitters.

• A software control system containing similar algorithms as the production

processes at Sandvik Coromant, for instance it might be of great relevance to

use a PID controller.

• An operator interface illustration that follows the physical process. The operator

environment should also contain an alarm list.

• A course compendium with both general information about functions in DeltaV

and instructions on how to create the same control system as the one which was

developed in this project.

1.1.5 Aim

The aim of this project was to make a test platform along with a course compendium.

The test platform should be portable so that it can be brought to people for education in

DeltaV regardless of where the persons are stationed. This education should give a

general knowledge on how to use DeltaV and after completing this course the engineers

should be able to implement simple control systems.

1.2 DeltaV-a DCS automation system

In industry there are different automation systems; some that are more basic and some

that are more advanced. This section will give an introduction to automation systems in

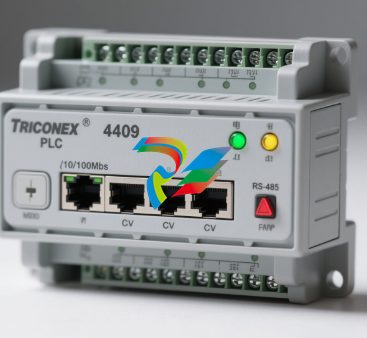

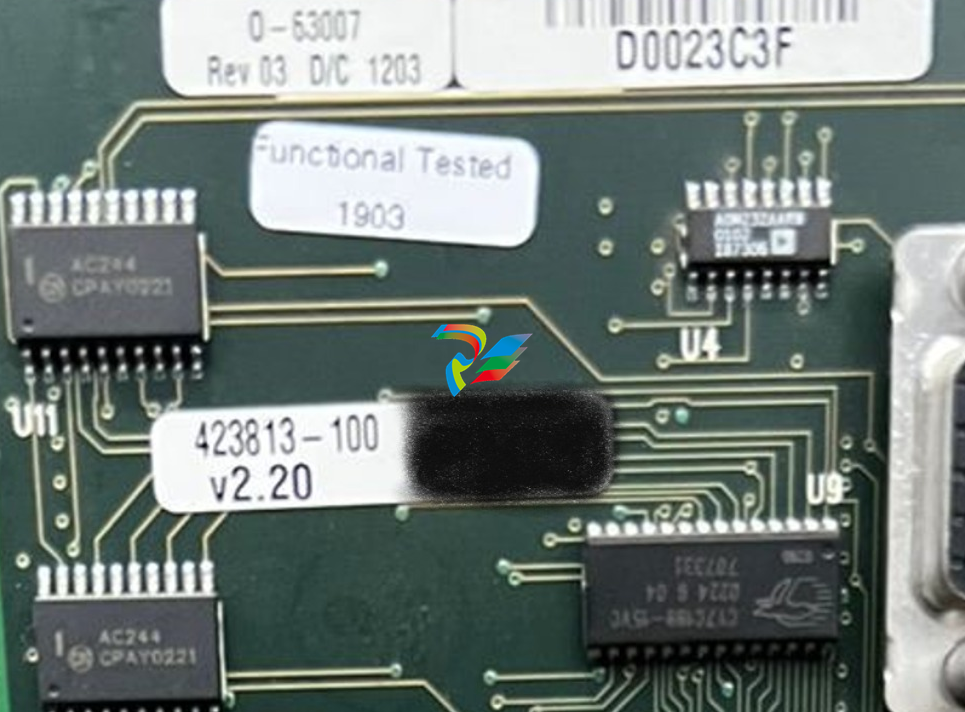

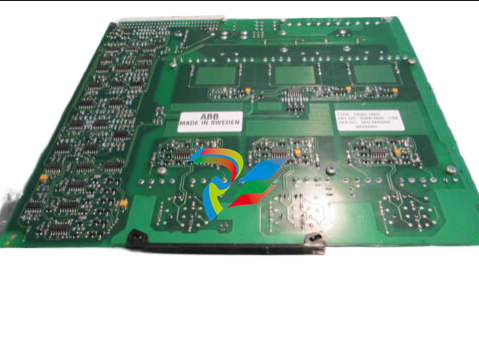

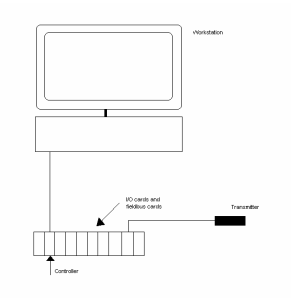

general and the specific automation system, DeltaV, that this project concerns. Figure

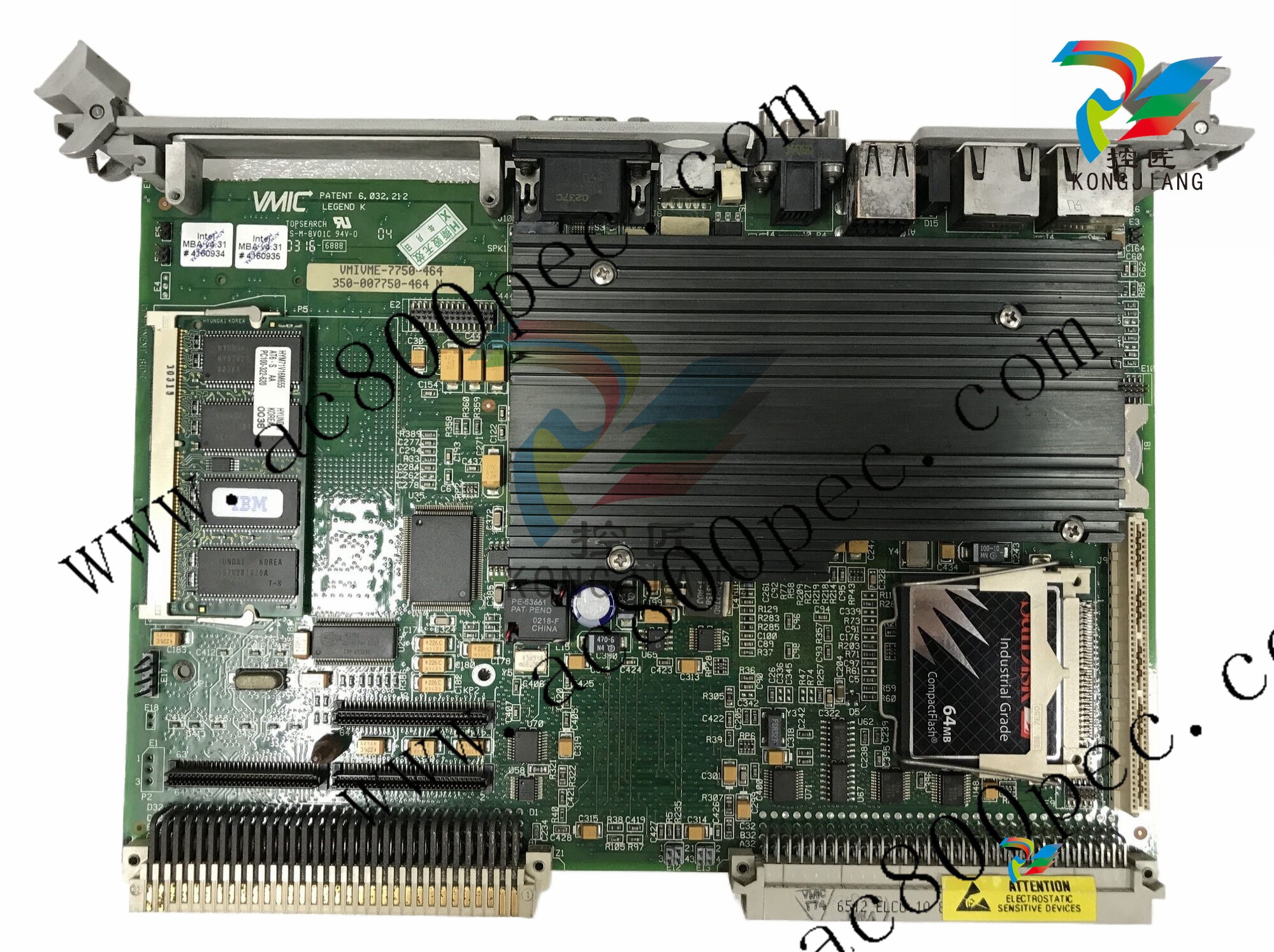

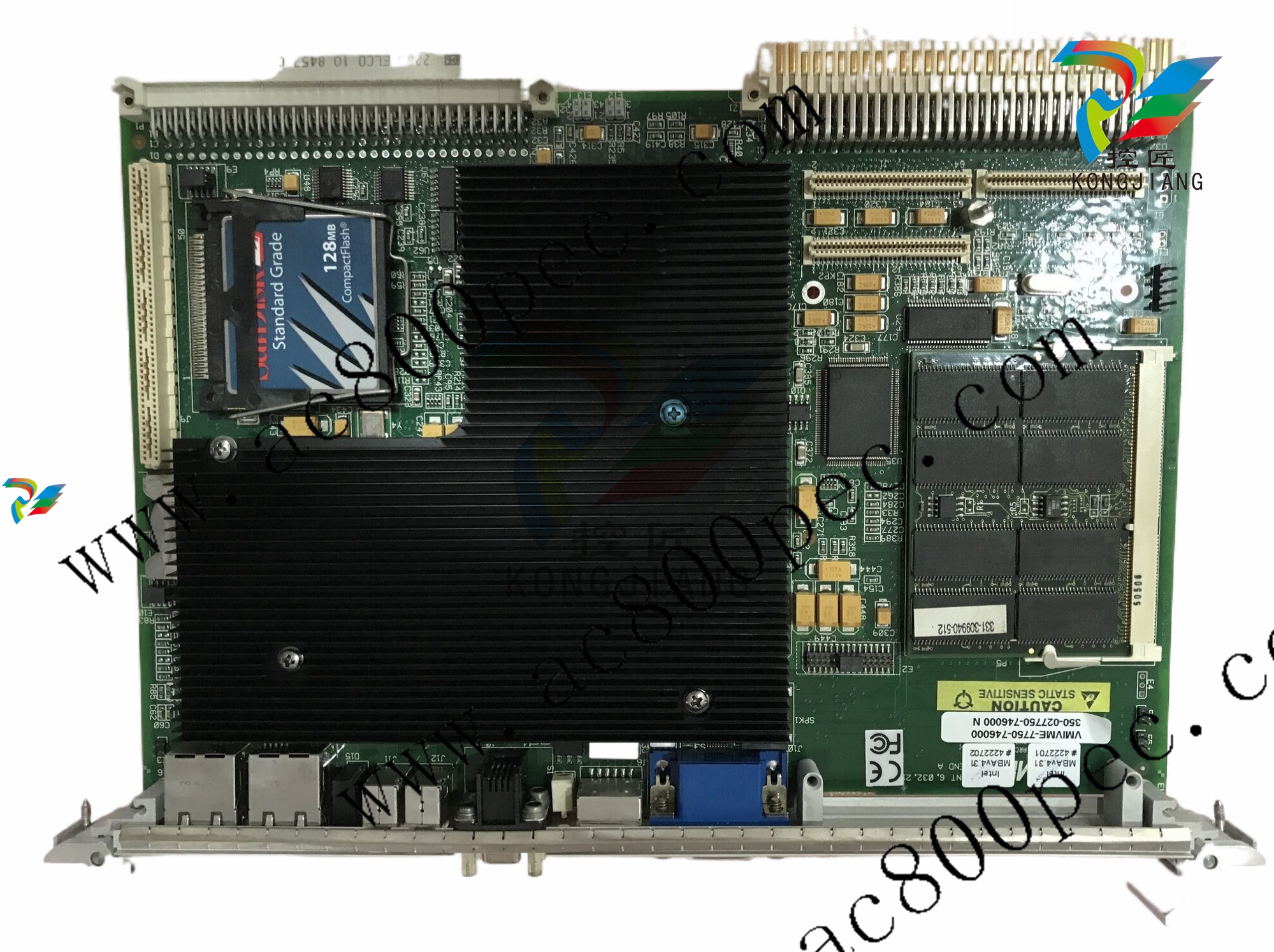

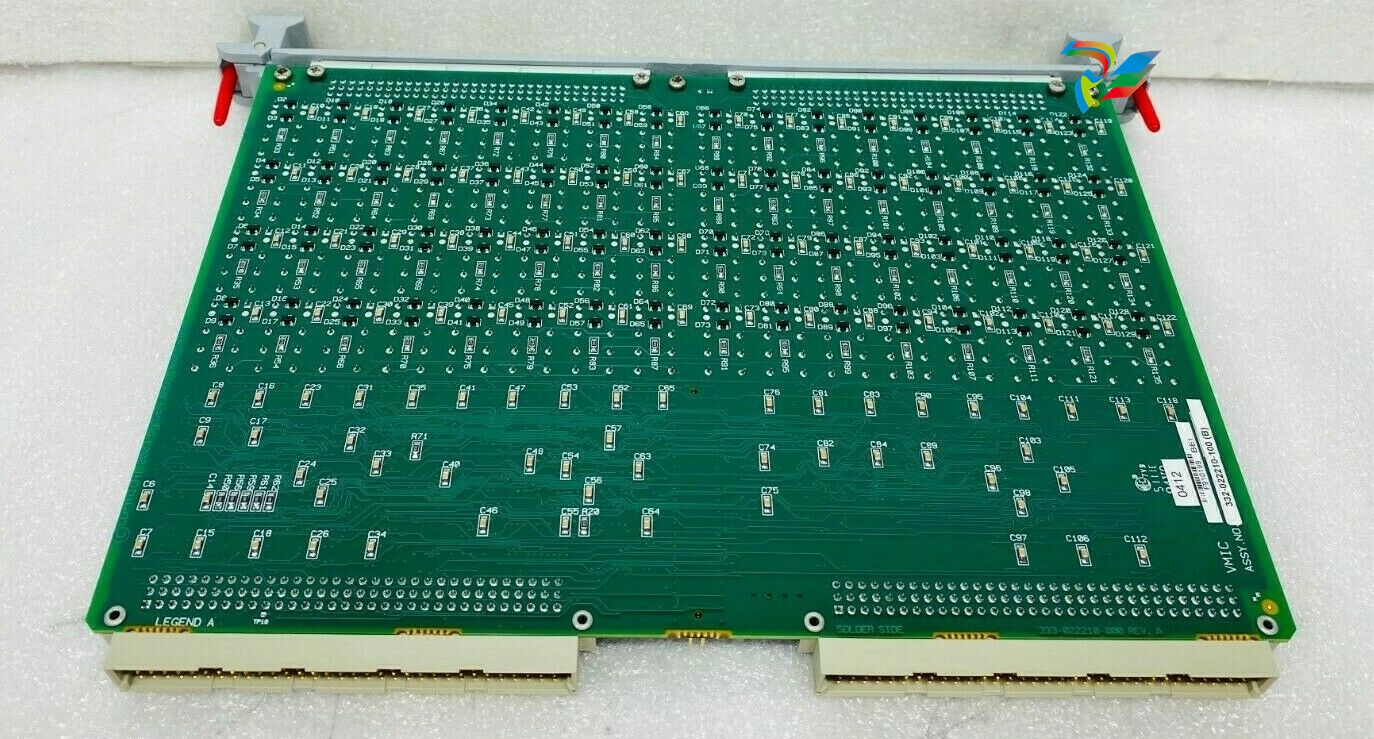

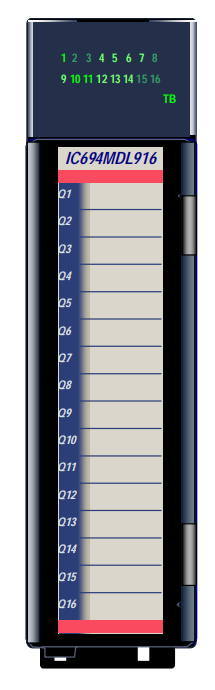

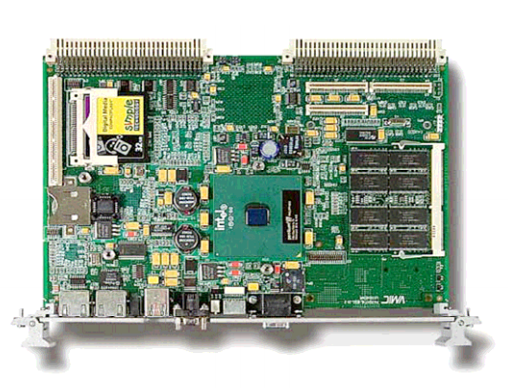

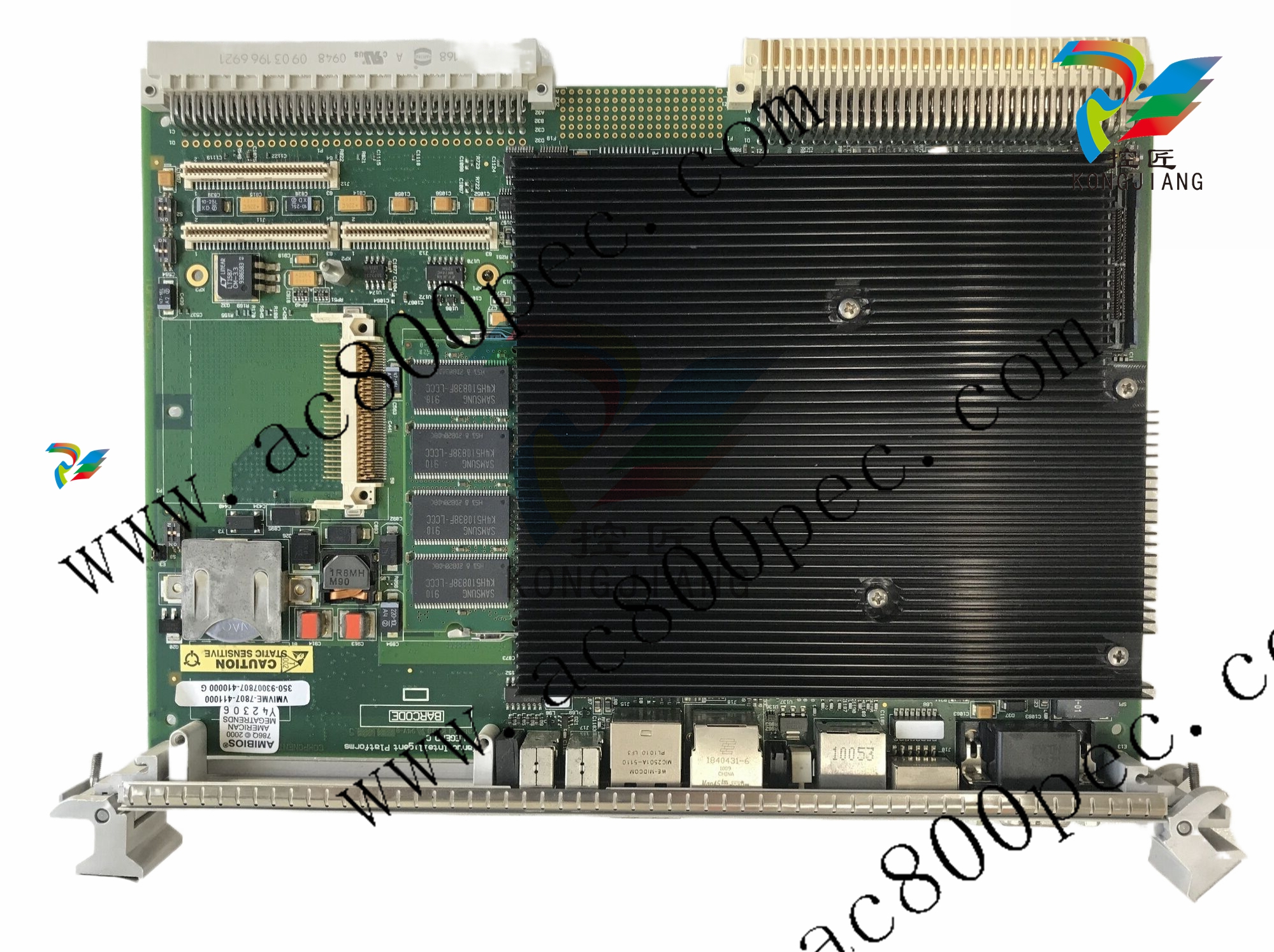

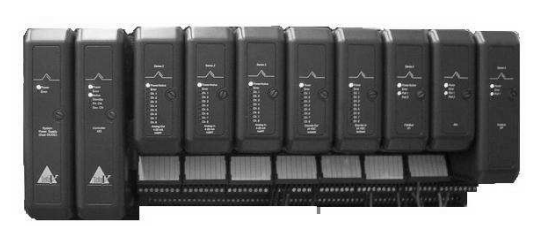

1.1 shows the hardware of the DeltaV automation system.

DeltaV is a DCS automation system. DCS is short for Distributed Control System and it

is and automation system that has evolved from PLC.[1]

PLC is short for Programmable Logic Controller. Originally PLC systems replaced old

automation systems that included many relays. PLC systems did then include only

discrete signals and when DCS was new, the difference between the two automation

systems was that DCS also included analog signals. However, today PLC includes both

analog and discrete signals and the difference between PLC and DCS is vague. Newer

designs look similar both in hardware and in software.[2]

The DeltaV automation system consists of one hardware part and one software part. In

the following subsections both parts willl be explained.

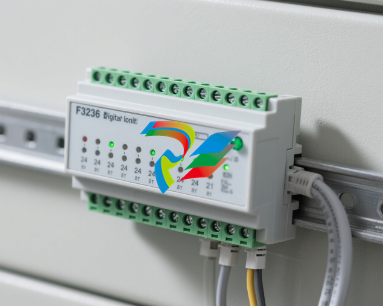

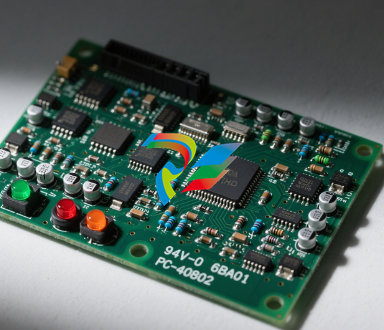

1.2.1 Controller, I/O and fieldbus cards

The hardware consists of controller cards, I/O cards and fieldbus cards.

In the controller a CPU is located and it is in the controller that the program containg

information on how to control the process is stored. This program is downloaded to the

controller from a workstation. The I/O cards and the fieldbus cards are capable of

sending or/and receiving signals to and from the devices. Hence, the I/O cards and

fieldbus cards send the signals that they get from the devices to the controller and the

signals that they get from the controller to the devices. The controller also sends

information to an operator interface, so that the operator of the process can monitor it.

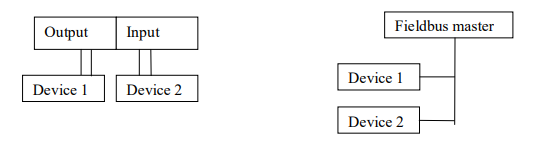

Figure 1.2 shows an overview of the connections for an automation system.

Figure 1.2. Overview of the connections for an automation system. A device is connected to an I/O card

or a fieldbus card. The controller communicates with the I/O cards and the fieldbus cards and is connected

to a workstation. The program is downloaded from a workstation to the controller.

Figure 1.3. The network is reduced when using a fieldbus. Fieldbus cards allow communication in both

directions and the wiring is much less when using fieldbus cards.

In this project three fieldbus cards are used; Foundation Fieldbus, Profibus and ASInterface. Foundation Fieldbus and Profibus handle analogue signals and AS-i only

handles discrete signals.

The communication technology for all three fieldbus cards follows a standard model

called OSI (Open Systems Interconnection). An OSI model divides the functions of a

protocol into several layers. Each layer uses only the functions of the next layer, and

only exports functionality to the preceding layer. The main feature of the OSI-model is in

the interface between layers which dictates the specifications on how one layer interacts

with another. This enables that a layer written by one manufacturer can operate with a

layer from another. The OSI model contains seven layers, but the fieldbus model is only

based on three major layers (layers 1,2 and 7 in the OSI-model). [3]

AS-Interface (AS-i)

AS-i is the most simple fieldbus. It is designed for connecting binary devices.

The OSI-model consists of three layers; Transmission Control, Execution Control and

Application Layer Interface.

The Transmission Control includes the wiring of the field devices and other components

in the process. This layer receives messages and encodes them to physical signals.

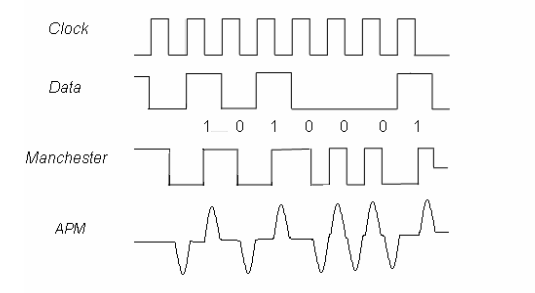

The signals which are in NRZ code (non-return-to-zero code) are encoded using

Manchester II coding and then implemented with APM coding.

The principle of Manchester encoding is that every bit period has one transition in the

middle of the period. A positive transition represents a logic one and a negative

transition represents a logic zero. Transitions that are not in the middle of the bit period

do not carry any useful information. These transitions only have the purpose to set the

signal in the state where the mid-bit transition can take place.

With APM, pulses are created; a positive pulse is created at a low to high edge and a

negative pulse is created at a high to low edge. In figure 1.4 the coding principle for both

manchester encoding and APM is shown. [4][5]

Figure 1.4. Illustration of the principle for the Manchester encoding and APM encoding. The data is coded

to Manchester code so that a transition occurs in the middle of every bit period. A positive transition

represents a logic one and a negative transition represents a logic zero. Transitions that are not in the

middle of the bit period do not carry any useful information. These transitions only have the purpose to set

the signal in the state where the mid-bit transition can take place.

The Execution Control is of Master/Slave characteristic. The AS-i card works as the

network master. The master automatically controls all communication over the AS-i

cable. The master interrogates all the available AS-i addresses and repeats the process.

The Application Layer Interface makes it possible to download the DI and DO functions

to the controller. This enables communication between the controller and the devices. [6]

Foundation Fieldbus

The Foundation Fieldbus card used in this project is H1. As compared to another

foundation fieldbus card H2, the H1 network is a lower speed and lower cost network

than H2.

The communication for foundation fieldbus follows the OSI model with three layers;

Physical Layer, Communication Stack and User Application.

The Physical Layer includes the wiring of the field devices and other components in the

process. This layer gets encoded messages from the next layers and converts them into

physical signals. The signals are encoded using the Manchester Biphase-L technique.

In manchester Biphase-L code a positive transition in the middle of a bit period

represents a logic zero and a negative transition in the middle of a bit period represents

a logic one, see figure 1.5.

Figure 1.5. Encoding with Manchester Biphase-L technique. In manchester Biphase-L code a positive

transition in the middle of a bit period represents a logic zero and a negative transition n the middle of a bit

period represents a logic one [5]

The Communication Stack is the layer that manages communication between a device

and a host or the communication between two devices.

In foundation fieldbus communication with H1, the H1 card works as a Link Active

Scheduler (LAS). A LAS is a deterministic, centralized bus scheduler that maintains a list

of transmission times for all the data buffers in all the devices that need to transmit in

cyclical fashion. [7] Field devices may also have Link Master capabilities and would in

the case that the H1 card fails, work as LAS. The H1 card is the only primary Link

Master allowed on the fieldbus segment. No other Link Master is allowed on the

segment or unpredictable results can occur. DeltaV supports one backup Link Master

device on each fieldbus segment.[8]

The communication between LAS and publishers and subscribers can be scheduled or

unscheduled.

Scheduled communication-The LAS maintains a list of transmit times for all data buffers

in all connected devices. When it is time for a device to transmit its data, the LAS sends

a CD (Compel Data) to that device. The device publishes (sends) data to all devices on

the fieldbus. The devices which are configured to receive the data are called

subscribers.

Unscheduled communication- These transmissions are done with PN (Probe Node) or

PT (Pass Token) and take place between transmissions of scheduled messages. The

LAS sends a PN (Probe Node) message to see whether any device changes have been

made. The changes are added to a live list. It is possible for a device to transmit

unscheduled messages after it has received a PT (Pass Token) from the LAS.

The User Application is a standard user application defined by Fieldbus Foundation.

This layer is not defined by the OSI-model. [9]

Profibus

The Profibus that is used in the test platform is Profibus DP (Decentralized Periphery).

Profibus DP is the most common Profibus.

The OSI-model for Profibus communication consists of three layers;

The Physical Layer defines the physical transmission characteristics. The signals are

sent using UART (Universal Asynchronous Receiver/Transmitter). With UART, data are

transmitted as streams of characters. Every character starts with a start bit (a 0) and

ends with a stop bit (a 1). The start bit allows the receiver to recoginize the start of a

new character and the stop bit makes sure that there will be a transition at the start of

the stop bit. [10]

The Communication Stack is a communication layer which defines the Bus Access

Protocoll. In a Profibus DP system the communication type is master/slave and both

multi-master and mono-master systems are possible. The protocoll used is Media Acces

Control (MAC), which specifies the procedure when a station is permitted to transmit

data on the bus. The MAC must ensure that only one station has the right to transmit

data at a time.

Hence, the requirements on the MAC protocol are that the following should be

accomplished:

• During communication between master stations it must be ensured that each of

these masters gets sufficient time to execute its communication tasks within a

precisely defined time interval.

• Cyclic, real time data transmission is to be implemented as fast and as simple as

possible for communication between a master and its slaves. [11]

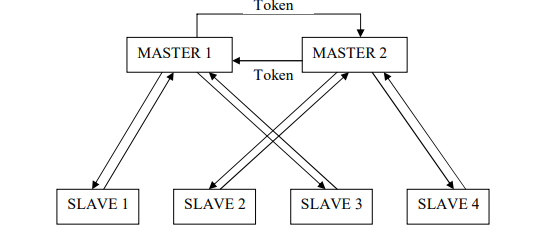

The multi-master system manages communication by having a token that is sent

between the masters. When a master has the token, it can communicate with its slaves,

see figure 1.6. [12]

Figure 1.6. The multi-master communication of Profibus. The multi-master system manages

communication by having a token that is sent between the masters. When a master has the token, it can

communicate with the slaves.

The User Layer is defined as a standard user layer. [13]

1.2.2 Description of the Software tools in DeltaV

The automation system has many different software applications. For this process the

applications that have been used are: A tool for organizing the database, a tool for

creating control modules and an animation tool for creating operator interfaces.

The Database

A database contains controllers, I/O and fieldbus cards in the system and control

modules.

The Control Modules

In DeltaV the control of the system can be organized in control modules. A control

module can be very simple and contain only one or two input parameters. It can also be

more complex with for instance PID-control.

There are several types of control modules. Which one is used depends on its purpose.

The most important control modules are;

• Function Block Diagrams (FBD)

An FBD is always necessary to be able to send signals from the computer to the

process or get signals from the process to the computer. An FBD consists of, as

the name tells us, function blocks. A function block can be an input block, for

instance it can contain a signal from a temperature transmitter. If this signal value

should be shown on the operator interface, there must be a reference from the

module containing this block to the operator interface. For each signal, only one

input/output block can be used. It is possible to get the signal at another place, for

instance in a different control module, by referring to it. Other function blocks are,

for instance, multipliers and PID blocks.

• Sequential Function Charts (SFC)

An SFC is a control module for determining the sequence of execution. A SFC

consists of a bipartite graph (two states are always separated by a transition). In a

State, actions can be permormed. This means that parameter values can be set,

for instance a light connected to a relay that gets a signal from the automation

system can be switched on. Transitions contains the conditions that need to be

fulfilled for the process to change states. In an SFC references are made to the

FBDs. For instance, if it is desired to have a transition when the pressure is above

1200 mbar, there must be a reference to the input block in the specific FBD that

gets an input from the pressure transmitter.

The Operator Interface

The tool for creating an operator interface is object based. It contains images of valves,

engines, fire etc. The objects can be animated which makes it possible to create an

operator environment in which the operator can easily get an impression of the state of

the process.

1.3 Report Outline

This report is arranged as follows:

Chapter 2 - The platform and the course material presents how the hardware as well as

the software for the test platform have been developed.

Chapter 3 - Results presents the result, i.e. the finished test platform.

Chapter 4 - Conclusions presents the conclusions of this project. The chapter also

presents a few suggestions on how the test platform can be improved.

Chapter 2

The platform and the course material

The following chapter will present the platform and the system design; firstly the devices

that are present and how the physical process works and secondly the course material.

2.1 The system design

When choosing the system design the requirements presented in Section 1.2.4 were

first

and foremost taken into account. When considering the purpose of the test platform an

addition was made to the requirements:

• To make a process that is easy to understand, but that is adequately advanced

for using advanced control tools in DeltaV.

With these requirements a system design was developed. The principle of the process is

briefly described below. Figure 2.1 illustrates of the principle of the process.

A pressure tank with a needle valve is filled half way up with water. When the control

system starts, air flows into a tank through a mass flow controller and the pressure in the

tank is controlled to stabilize around ~1500 mbar.

When the pressure has been held around 1500 mbar for a specified time a pneumatic

valve will open and tap out water into an open tank that is placed below the pressure

tank. The valve will stay open until a level sensor indicates that the tank is full.

When the open tank is full a heating plate will start to heat up the water. The

temperature is controlled with on/off controlling to ~35 ºC.

To continue the process the open tank has to be removed, emptied and put back in

place. This will restart the process. This can be repeated until the pressure tank is

empty.

• Buttons

The button device consists of one red button with red light and one green button

with green light. The buttons can also be lit.

Devices connected to Foundation Fieldbus

• Pressure transmitter

A pressure transmitter measures and transmits the pressure value.

• Temperature transmitter

A temperature transmitter measures and transmits the temperature.

Devices connected to Profibus

• Mass Flow Controller

A mass flow controller controls the inflow of gas from one place to another.

Devices connected to Discrete Out

• Relays

A relay is a device that can control other devices with on and off.

Devices connected to relays

Light bulb

Heat plate

• Valve Island

A Valve Island is a device with several electrically controlled valves. The valves

are normally closed, but they open when they receive a signal from the controller.

Devices connected to Discrete In

• Capacitive Proximity Sensor (Level Transmitter)

A capacitive proximity sensor is used for detecting objects that are proximal to the

sensor.

Other objects in the test platform

• Pressure tank

A pressure tank was constructed for the test platform. It is designed to be able to

handle a pressure of 10 bar and to contain both water and air. It has four

connections; one that can be connected to the mass flow controller, one that can

be connected to the pressure transmitter, one that can be connected to the

needle valve and one that can be connected to a pneumatic valve. It also has one

inflow so that it can be filled with water.

• Open tank

The open tank is a much less advanced tank than the pressure tank. It is open

and therefore it must not be able to handle any pressure and it does not have any

connections. It is metallic so that it can be detected by an inductive proximity

sensor.

• Pneumatic Valve

A pneumatic valve is normally closed, but opens if it is exposed to pressurized air.

• Compressor / Pressurized air media

Depending on where the platform is used a compressor or pressurized air media

is used. A compressor is used when there is no pressurized air media available.

Since a compressor has a high sound level and in addition is heavy to carry it is

only meant to be used when there is no other option.

Detailed description of the Physical Process

1. DeltaV controller, I/O and

fieldbus cards

2. Pressure transmitter

3. Mass Flow Controller

4. Valve island

5. Inductive Proximity Sensor

6. Capacitive Proximity Sensor

7. Temperature Transmitter

8. Push buttons

9. Relays

10. Heat plate

11. Light bulb

12. Pressure tank

13. Needle valve

14. Pneumatic valve

15. Open tank

As mentioned the physical process is a process with no actual purpose. The only

purpose is to have a physical process to follow while learning how to use DeltaV. In the

previous subsection all devices and other things in the physical process were described.

This section will instead focus on how the devices are used to create a functional

automated process.

Figure 2.2 illlustrates how the objects in the process are connected.

Before starting the process, the pressure tank is partly filled with water and the open

tank is empty. On the button device the red light is on. A compressor that is not included

in the control should be switched on by the operator. (The compressor could as

mentioned above be exchanged with pressurized air media). The compressor exposes

the valve island with pressurized air.

The process is started by pressing a green button. This button exists both in the

operator interface and physically on the test platform. When the button is pressed the

green light on the button device will be switched on and the red light which indicates that

the process is off will be switched off. The valve island will open the valve that is

connected to the mass flow controller. The Mass Flow Controller will then be exposed to

pressurized air.

The mass flow controller will control the pressure in the pressure tank so that it stabilizes

at approximately 1500 bar. The control is done with the software with PID control. How

the PID parameters are set, is described in the Subsection 2.2.2.1.

When the pressure in the pressure tank has been between 1400 mbar and 1600 mbar

for one minute, the inductive sensor signals that the open tank is in its place below the

pressure tank and the capacitive signals that it is not already filled with water, the valve

island will open the valve that is connected to the pneumatic valve. When the pneumatic

valve is exposed to the pressurized air from the valve island, it will open and water will

flow out from the pressure tank.

The valve on the valve island that is connected to the pneumatic valve will be open until

the capacitive sensor indicates that the water level is high. The pneumatic valve will

close when it does no longer get pressurized air from the valve on the valve island.

If the water temperature is less than 35 C, the heat plate starts heating. The heater will

only start if there is a tank filled with water on it.

When the water temperature has reached 35 C, the heating will stop. For the process

to go on, the open tank has to be removed, and put back. This will bring the process

back to the state when the pressure in the tank is controlled to be between 1400 and

1600 mbar. From that state it will continue and the process can go on until the pressure

tank is empty.

If the open tank would not have been emptied when the water temperature was higher

than 35 C, the heating would have started all over again when the temperature is below

35 C. The heating will always start when the open tank is in place and filled with cold

water, unless the red button (the emergency button) has been pressed.

The red button can be pressed at any time in the process and the process will enter its

standby state. In the stand by state everything is off except for the red light on the button

device which is on.