AMAT 0041-75950 Technical Overview

AMAT 0041-75950 Technical Overview

Single-Zone CVD Reactor & Sym3 Etch ESC Technology

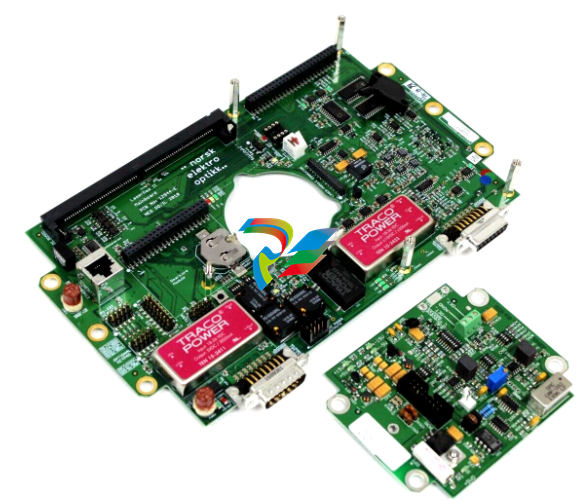

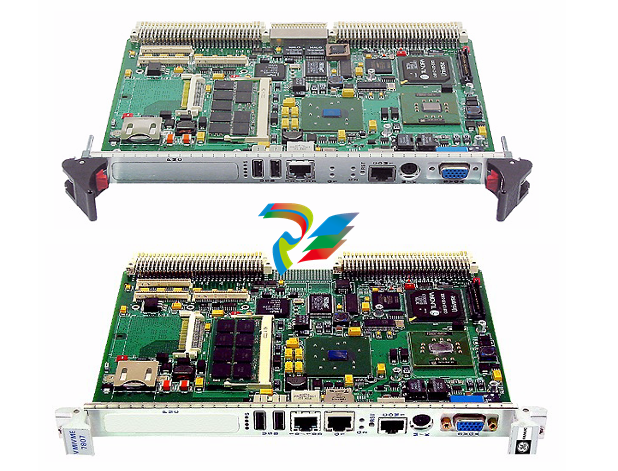

Introduction to AMAT 0041-75950

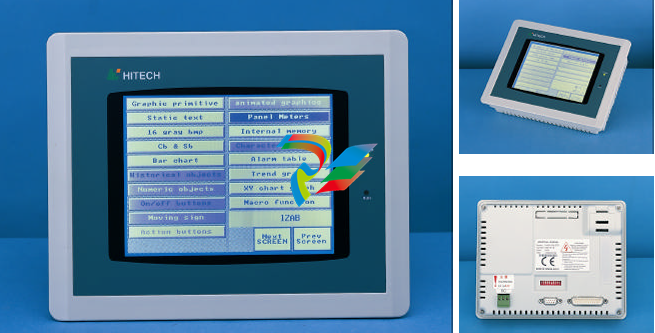

The Applied Materials (AMAT) 0041-75950 is a versatile semiconductor manufacturing component that serves in dual capacities: as a Single-Zone Chemical Vapor Deposition (CVD) Reactor and as an Electrostatic Chuck (ESC) component for the Sym3 Etch Chamber. This technical article explores the specifications, applications, and technological significance of this critical semiconductor manufacturing component.

.png)

Dual-Purpose Component

The AMAT 0041-75950 demonstrates Applied Materials' engineering excellence in creating multi-functional components that can be integrated into different semiconductor processing systems. The part's versatility allows it to function both as a critical element in CVD film deposition processes and as an advanced electrostatic chuck for precision etching in Sym3 chambers.

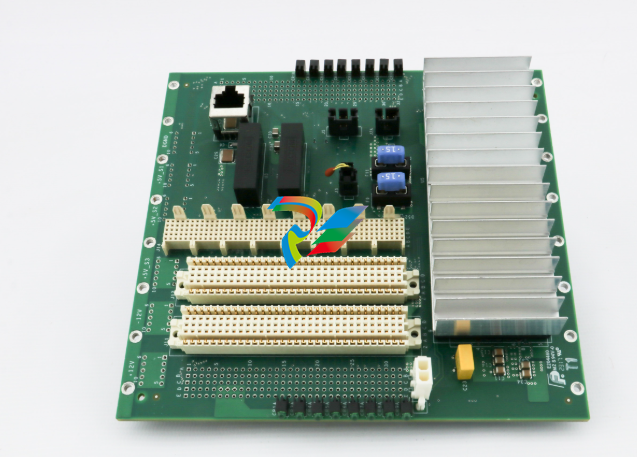

Single-Zone CVD Reactor Specifications

As a Single-Zone CVD Reactor, the AMAT 0041-75950 is designed to deliver exceptional thin film deposition capabilities for semiconductor manufacturing. Below are the key specifications and features:

| Specification | Details |

|---|---|

| Part Number | 0041-75950 |

| Component Type | Single-Zone Chemical Vapor Deposition (CVD) Reactor |

| Wafer Compatibility | 200mm and 300mm |

| Temperature Control | Single heating zone with precise temperature regulation |

| Process Types | Thermal and Plasma CVD processes |

| Gas Flow Design | Low-turbulence gas distribution system |

| Chamber Actuation | Hydraulic actuation mechanism |

| Film Deposition Capability | Silicon Nitride, Silicon Dioxide, and other dielectric films |

High-Quality Film Deposition

The 0041-75950 reactor is designed for depositing uniform, high-quality thin films essential for modern semiconductor device fabrication, with excellent control over film properties and composition.

Precise Temperature Control

The single-zone heating system provides accurate temperature regulation across the deposition surface, ensuring consistent film quality and properties throughout the process.

Process Versatility

Capable of supporting both thermal and plasma-enhanced CVD processes, this reactor offers flexibility for various deposition requirements in advanced semiconductor manufacturing.

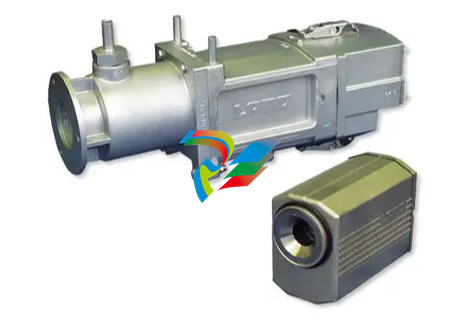

Sym3 Etch Chamber ESC Applications

When integrated into the Sym3 Etch Chamber system, the AMAT 0041-75950 functions as a critical Electrostatic Chuck (ESC) component for advanced etching processes:

Sym3 Etch Technology Overview

The Sym3 etch technology represents Applied Materials' most advanced etch platform, used for creating precise, high-aspect-ratio features in modern semiconductor devices. Key aspects of the Sym3 system that leverage the 0041-75950 include:

True Symmetry™ design with symmetrical architecture for power, gas delivery, and thermal characteristics

High-conductance chamber architecture for exceptional etch profile control

Pulsed RF technology for superior material selectivity and depth control

Precision handling of advanced memory and logic chip production

ESC Functionality

As an Electrostatic Chuck component in the Sym3 system, the 0041-75950 provides:

Secure wafer clamping during high-precision etching processes

Uniform thermal control across the wafer surface

Enhanced RF power delivery for plasma processes

Reduced particle contamination through advanced materials and design

Support for critical etch processes in 3D NAND, DRAM, and advanced logic fabrication

Key Advantage: The 0041-75950 ESC component helps enable the Sym3 system's ability to create densely packed, high-aspect-ratio structures essential for modern semiconductor architectures, including FinFETs and gate-all-around (GAA) transistors.

Technical Applications

CVD Applications

As a single-zone CVD reactor, the 0041-75950 is utilized in the following deposition processes:

Dielectric Layer Deposition: Silicon dioxide (SiO₂) and silicon nitride (Si₃N₄) for isolation and insulation layers

Passivation Layer Formation: Protection layers for completed semiconductor devices

Inter-Metal Dielectric (IMD) Layers: Insulation between metal interconnect layers

Shallow Trench Isolation (STI): Deposition of oxide films for device isolation

Pre-Metal Dielectric (PMD): Insulating layer between transistors and first metal layer

Etch Applications

When used as an ESC in the Sym3 etch chamber, the 0041-75950 supports these critical etching processes:

Conductor Etch: Precision patterning of metal lines and interconnects

High-Aspect-Ratio Feature Creation: For 3D NAND memory stacks and advanced logic architectures

Critical Dimension (CD) Control: Maintaining precise feature dimensions across the wafer

Profile Control: Ensuring vertical sidewalls and consistent etch profiles

EUV Patterning Support: Enabling precise etching of features defined by EUV lithography

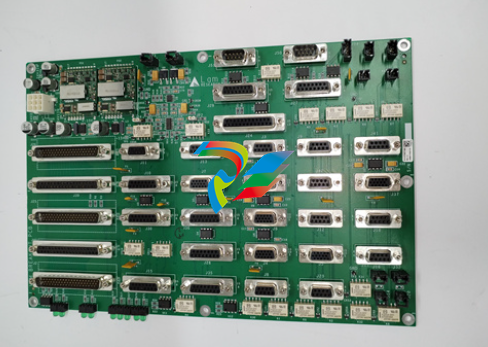

Integration with Applied Materials Systems

CVD Integration

The 0041-75950 CVD reactor can be integrated with the following Applied Materials platforms:

Producer Platform: For 200mm and 300mm wafer processing with Twin Chamber® architecture

Centura Platform: For sequential process integration with other deposition or etch modules

Standalone Single-Chamber Systems: For specialized research and development applications