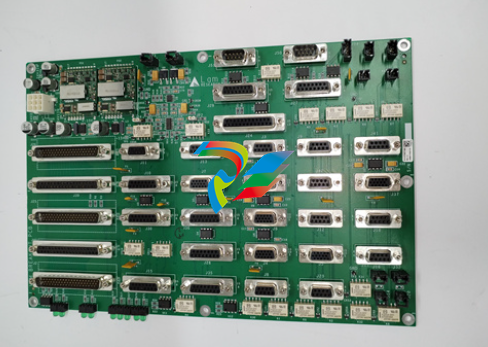

LAM 810-069751-114 RF/DC interface board

LAM Research 810-069751-114 is an RF/DC Interface PCBA specifically designed for the LAM 2300 series (including Flex, Kiyo, Versys) and Alliance platforms.

In the semiconductor etching process, the main task of this board card is to serve as a communication link between the machine's main control system and the radio frequency (RF) generator or DC bias power supply.

1. Core technical functions

The 810-069751 series board card is a key link in the control chain of the process Chamber.

RF control signal distribution: It receives instructions from the autonomous CPU and converts them into analog or digital signals that the RF generator can recognize, which are used to control the on/off and power regulation of the plasma.

Status monitoring: Real-time monitoring of the feedback signals of the RF system (such as reflected power, forward power) to ensure the stability of the plasma during the etching process.

Safety Interlock (Interlock) : If the RF Match Network or power supply fails, this board card will immediately cut off the signal through the hardware link and issue a pause command to the system (and KUKA robot) to prevent damage to the wafer.

2. Position in the KUKA robot system

In the KRC2 controller architecture you mentioned earlier, 810-069751-114 belongs to the feedback layer of the execution end:

Ready signal: When the KUKA robot feeds the wafer into the chamber and exits, the host starts the RF process through this board card.

Process completion notification: Once the board detects that the RF power has dropped to zero and the process is complete, it will send a signal to VIOP III (810-046015-010), and then DSE-IBS will notify the robot that it can enter the chamber to retrieve the wafer.

3. Meaning of Model Suffix (-114)

The part number suffix of LAM usually represents different hardware revision versions or specific process matches:

-114 usually represents Revision B or C, which improves electromagnetic compatibility (EMC) on the basis of the earlier -00x or -110 versions. As this board operates near a high-frequency RF environment, the -114 version has enhanced the shielding performance to prevent high-frequency noise from interfering with other sensitive boards (such as analog AIO boards) on the VME bus (810-066. 590-004).

4. Common Fault Manifestations

If 810-069751-114 is damaged or aged, the following usually occurs:

"RF On Failure" : The system issues the startup command, but the generator does not respond.

"RF Reflection High" (False alarm of excessive reflection power) : In fact, the RF matching is normal, but the feedback voltage collected by the board card deviates, causing the system to shut down protectively.

Communication timeout: This causes the KUKA robot to remain in a state of "waiting for the process to start" for a long time after completing the wafer placement.

Maintenance suggestions

Clean the connectors: This board card is usually connected to multiple sets of ribbon cables. As there may be trace amounts of corrosive gas in the etching workshop, it is recommended to regularly check the interfaces for any green signs of oxidation.

Check with the power supply: As it requires a stable low-voltage direct current to process signals, if the output of the PH1003-2840 power supply is unstable, it will cause the RF control signal to jitter, directly affecting the uniformity of etching.

Your LAM system puzzle update

At present, you have collected the following core links

Power layer: PH1003-2840

Transport/Structural Layer: 810-066590-004 (Backplane)

Control/Clock Layer: 810-072907-005 (Clock Controller)

Input/Output Layer: 810-046015-010 (VIOP) & 810-099175-012 (AIO)

Execution interface layer: 810-069751-114 (RF interface)

Robot motion layer: DSE-IBS 3.02 & KSD1-08

| User name | Member Level | Quantity | Specification | Purchase Date |

|---|