Smart Gauging Systems Improve Tank Farm Efficiency

But improved tools for addressing issues are not enough, as they need to be supplemented with diagnostics. In many cases, field devices sit untouched, without much idea of instrument health, until a process is disturbed, leading to unplanned, reactive maintenance activities. Using advanced tank gauging systems, personnel can access a history of events, current device status and health, and recommended remedies without spending any time at or on the tank (Figure 2).

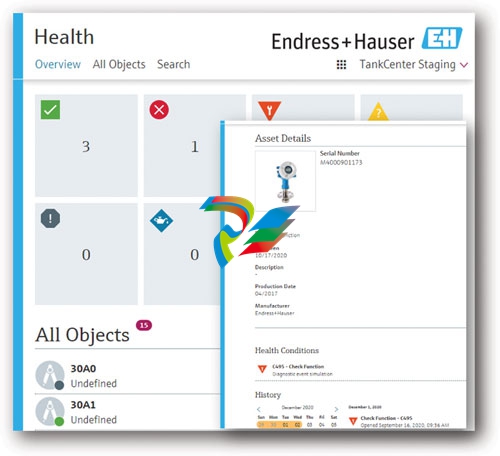

By connecting this local process, diagnostic, and event data to the cloud, advanced computing becomes possible, providing a health status asset dashboard and proactive maintenance insights. Using cloud connections and analysis engines, centralized software can observe patterns, create connections between historical input conditions and output results, and use these patterns to generate insights (Figure 3).

Hardware, instrumentation and communication configuration

A complete tank gauging system consists of instrumentation for measuring level and temperature and a scanner device in an electrical room to transmit data to a local or cloud-based information repository. Instruments must communicate via digital field protocols, such as HART, to send numerous diagnostic and process data points to the scanner device. A typical scanner can connect directly to a local database, or to an edge device, for uploading data to the cloud (Figure 4).

Although asset information is often stored manually today, advanced tank gauging systems give users access to a cloud-based library for asset information by scanning a QR code on each device. The resources include the right user manuals (Figure 5), associated product certificates, and instrument calibration information, with data uploaded at the time of automatic calibration procedures.

Outdated tank farm at a refinery

A refinery with a tank farm previously used traditional level sensors installed on top of the tanks. On multiple occasions, an allocation manager noticed a significant error during a product mass balance reconciliation. This required notifying operations staff and investigating further.

Operations personnel then verified levels in the storage tanks by performing manual dipping procedures, identifying differences in readings between the manual dips and the level sensor readings for each tank. Once this was done, they manually created a report of their findings, and sent this to the maintenance department.

Using this report, maintenance personnel created a work order in a disparate work management system, then sent specially trained staff to remediate the identified instrument issues. This frequently required multiple trips back and forth between the tank and the shop to exchange tools and consult user manuals.

Retrofit with a modern tank gauging solution

To reduce the effort required to identify, validate, and address these frequent problems, and to improve personnel safety and productivity, the refinery retrofitted its existing equipment using smart instruments and a liquid tank gauging solution. This provided a path to proactively address these sorts of issues with state-of-the-art Industrial Internet of Things (IIoT) technology.

The new level instrumentation came fitted with round-the-clock self-diagnostic capabilities with a connection to the liquid tank gauging solution health app. This app constantly monitors level sensor health, reporting the information to the dashboard and issuing alarms when anomalies are detected.

The refinery has had significantly fewer issues since the upgrade, but when anomalies or problems do arise, the system proactively identifies the issue without human intervention, automatically logging it and opening a work order in the connected computerized maintenance management system. It defines and categorizes the issue by device according to the NAMUR NE107 standard, and reports it immediately in the liquid tank gauging solution health app.

An alarm is sent to the maintenance department, and a technician logs in to the app to confirm the alarm and read the diagnostic information, including root cause, suggested remedy, and a link to the user manual. Alarm details are also provided, identifying the time the anomaly or problem was detected.

Fully informed of the context, the technician is empowered to grab the right tools the first time before venturing to the tank. And in the event specialized technical support is required, AR goggles provide a means for additional guidance from a remote technical expert with intimate knowledge of the system. This third-party support alleviates the need for the refinery to hire and retain highly technical talent.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)