Smart Gauging Systems Improve Tank Farm Efficiency

IIoT-ready instrumentation can quickly enable data-driven reductions in failures and downtime.

The second law of thermodynamics states the total entropy—or natural disorder—of any system increases or remains the same in a spontaneous process. This is a foundational facet, one of the building blocks of thermal physics at the molecular level, and regardless of debate among physicists, it almost always applies to visually tangible macrosystems as well.

This principle is arguably the strongest driver for control systems, given the whole point of control is to methodically manipulate inputs from an environment containing varying levels of disorder into specific outputs that bring about desirable outcomes. These points warrant the requirement of maintenance in every plant, because equipment naturally degrades over time. Mechanical components wear, electrical connections corrode, and even static objects degrade due to atmospheric contact, or exposure to chemicals and other hazardous conditions.

Putting a spotlight on tank farms, maintenance is necessary to ensure measurement accuracy and plant safety. Maintenance activities have evolved over the years, with new technology built into modern smart instruments, providing more methods to diagnose issues, share data and verify measurement integrity.

Historically, these activities had to be conducted manually, requiring technicians to perform tasks in the field, often in hazardous conditions. But data-rich sensors and intuitive software solutions are making it much easier to identify and address problems, so plant personnel can improve their productivity while reducing downtime and incidents.

Inevitable breakdown

Degrading measurements in a plant can be thought of analogously as degrading fuel economy in an automobile. As a car racks up more miles, its engine and other mechanical components slowly wear down, requiring more fuel to drive the same distance, thereby decreasing fuel efficiency. This drop may be miniscule at first, but it can become more significant over time.

In the same way, measurement errors as instruments degrade in a plant environment may be small at first—often unnoticeably so—but as wear compounds, measurement drift increases. Additionally, as instruments age, there is a higher chance of complete failure.

In the past, maintenance teams performed service at routine intervals to reduce the effects of measurement drift, as well as the chances of total failure. But this sort of calendar-based maintenance strategy is inefficient, because some instruments may not need service at their appointed time, while others may fail before the maintenance interval. When the latter occurs, maintenance must be performed reactively and expensively, and downtime often ensues.

For tank gauging applications, reactive approaches frequently begin when a mass balance issue is realized. Troubleshooting these types of issues with traditional instrumentation can take inordinate amounts of time. Operators must visit each tank, making individual manual measurements to determine the source of the measurement errors. Once the issue is identified, often hours or even a day later, maintenance teams are called out to repair the problematic instruments.

Online diagnostics increase reliability and uptime

Today’s smart instruments have a plethora of diagnostic data—one area of notable improvement over instruments of yesterday—and when combined with holistic tank gauging system solutions, operators can maintain their systems with much greater reliability. Instrument diagnostics and other functions make it easier to detect problems, with quicker troubleshooting and servicing when issues arise.

Centrally managed tank gauging systems provide a single repository for maintaining all components, including instruments, equipment, software, and maintenance devices. These systems can be easily connected to the cloud for enhanced monitoring and analysis solutions that generate insights, alerting maintenance teams of the ideal times to service instrumentation and equipment.

Using the software dashboard of these systems, operators can monitor field status at a glance, with anomaly and issue detection delivered via notification. When issues are detected, they are easier to troubleshoot because the system has predefined lists of error codes and descriptions, including cause and remedy. This can reduce the time spent troubleshooting and addressing issues in the field from hours to minutes.

Increasingly, these modern solutions are equipped with augmented reality (AR) capabilities. Field technicians put on a set of connected AR goggles, remotely projecting what they see to a support engineer. This engineer can reference diagrams and instructions on a computer in an office, and not only tell, but show, the technician which parts to adjust by using a virtual pencil tool to highlight the desired component, easing maintenance procedures significantly (Figure 1).

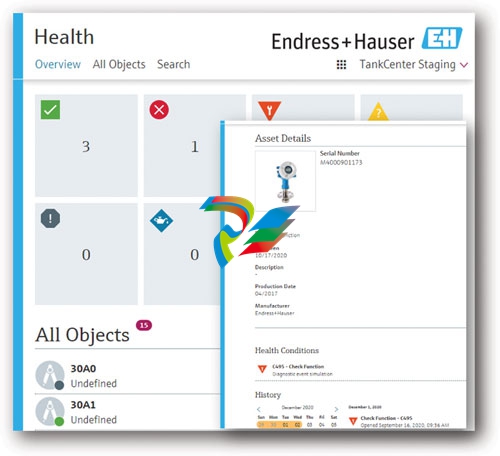

But improved tools for addressing issues are not enough, as they need to be supplemented with diagnostics. In many cases, field devices sit untouched, without much idea of instrument health, until a process is disturbed, leading to unplanned, reactive maintenance activities. Using advanced tank gauging systems, personnel can access a history of events, current device status and health, and recommended remedies without spending any time at or on the tank (Figure 2).

By connecting this local process, diagnostic, and event data to the cloud, advanced computing becomes possible, providing a health status asset dashboard and proactive maintenance insights. Using cloud connections and analysis engines, centralized software can observe patterns, create connections between historical input conditions and output results, and use these patterns to generate insights (Figure 3).

Hardware, instrumentation and communication configuration

A complete tank gauging system consists of instrumentation for measuring level and temperature and a scanner device in an electrical room to transmit data to a local or cloud-based information repository. Instruments must communicate via digital field protocols, such as HART, to send numerous diagnostic and process data points to the scanner device. A typical scanner can connect directly to a local database, or to an edge device, for uploading data to the cloud (Figure 4).

Although asset information is often stored manually today, advanced tank gauging systems give users access to a cloud-based library for asset information by scanning a QR code on each device. The resources include the right user manuals (Figure 5), associated product certificates, and instrument calibration information, with data uploaded at the time of automatic calibration procedures.

Outdated tank farm at a refinery

A refinery with a tank farm previously used traditional level sensors installed on top of the tanks. On multiple occasions, an allocation manager noticed a significant error during a product mass balance reconciliation. This required notifying operations staff and investigating further.

Operations personnel then verified levels in the storage tanks by performing manual dipping procedures, identifying differences in readings between the manual dips and the level sensor readings for each tank. Once this was done, they manually created a report of their findings, and sent this to the maintenance department.

Using this report, maintenance personnel created a work order in a disparate work management system, then sent specially trained staff to remediate the identified instrument issues. This frequently required multiple trips back and forth between the tank and the shop to exchange tools and consult user manuals.

Retrofit with a modern tank gauging solution

To reduce the effort required to identify, validate, and address these frequent problems, and to improve personnel safety and productivity, the refinery retrofitted its existing equipment using smart instruments and a liquid tank gauging solution. This provided a path to proactively address these sorts of issues with state-of-the-art Industrial Internet of Things (IIoT) technology.

The new level instrumentation came fitted with round-the-clock self-diagnostic capabilities with a connection to the liquid tank gauging solution health app. This app constantly monitors level sensor health, reporting the information to the dashboard and issuing alarms when anomalies are detected.

The refinery has had significantly fewer issues since the upgrade, but when anomalies or problems do arise, the system proactively identifies the issue without human intervention, automatically logging it and opening a work order in the connected computerized maintenance management system. It defines and categorizes the issue by device according to the NAMUR NE107 standard, and reports it immediately in the liquid tank gauging solution health app.

An alarm is sent to the maintenance department, and a technician logs in to the app to confirm the alarm and read the diagnostic information, including root cause, suggested remedy, and a link to the user manual. Alarm details are also provided, identifying the time the anomaly or problem was detected.

Fully informed of the context, the technician is empowered to grab the right tools the first time before venturing to the tank. And in the event specialized technical support is required, AR goggles provide a means for additional guidance from a remote technical expert with intimate knowledge of the system. This third-party support alleviates the need for the refinery to hire and retain highly technical talent.

Examining total cost of ownership

Frustration with the old instrumentation was not the only motivator for the previously mentioned refinery’s system upgrade. It also studied total cost of ownership (TCO), a critical performance indicator for evaluating the benefit of tank gauging systems. Typically, about 20 percent of this cost is attributed to initial purchase and startup costs, and 80 percent is attributed to operational costs. Although purchase price cannot be overlooked, operational costs are typically much more consequential over the life of these systems.

TCO can be reduced by:

standardizing with a tank gauging system

enabling cloud connectivity for enhanced monitoring and insights

implementing process and safety improvements

reducing time spent on top of the tank

eliminating obsolete equipment to reduce excess maintenance

engaging third-party support to reduce in-house technical expertise requirements.

From thermodynamics to business continuity

The second law of thermodynamics is not exclusive to physics classrooms and textbooks. Left unmitigated, efficiency in any electrical, mechanical, chemical, or other industrial system inevitably decreases over time. The old world of tank gauging systems required extensive manual intervention to address issues and maintain measurement accuracy, but the next frontier automates most of these tasks.

Equipped with smart instrument features in a central repository—such as self-diagnostics, automatic calibration verification, and record keeping—along with the computing and alerting capabilities of the cloud, modern tank gauging systems are empowering plant personnel to move away from reactive firefighting to proactive and predictive maintenance methods. This helps maintain measurement accuracy, improves personnel safety, and increases system uptime, leading to fewer delays in transfer and distribution, and greater business continuity and reliability.

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

_lVjBYb.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)