ABBAO2000-LS25 Laser analyzers

Isolation flanges For toxic gas and highly corrosive applications especially in combination with high pressure the first flange has to be an isolation flange which isolates the process from the analyzer. In these cases a shut-off valve is always necessary in order to do maintenance on the flange. The isolation flange has to be “custom tailored” for the individual process. The isolation flange may be purged if necessary as described in Section 3.1.2. Due to the additional windows a certain loss of transmission is to be expected. The analyzer will be mounted on the isolation flang

Before dismounting the isolation flange make sure the process is either turned off and safe or the volume between the nearly closed shut-off valve and the flange is purged thoroughly to make sure no harmful gas may leak out.

Leave the instrument switched ON, and disconnect both the transmitter and receiver units from their alignment units by loosening the corresponding mounting nuts. The laser beam from the transmitter is not visible. Avoid looking directly into the transmitter!

2. Remove the adapter ring (no. 4 in Figure 3-1) from the transmitter alignment & purging unit.

3. Mount the red laser alignment jig on the transmitter side using the supplied mounting nut and locate the laser beam on the receiver side using the target. Loosen the adjustment screws shown in Figure 3-4 on the transmitter unit purging flange and move it carefully from side to side and up and down to locate the laser beam in the receiver hole. (You may need two persons.)

4. Having found the laser beam, move the beam to the center of the hole by carefully adjusting the adjustment screws on the transmitter side. Lock the alignment by tightening the locking screws on the transmitter side and check that the alignment has not changed.

5. The laser beam is now centered, but not necessarily parallel with the optical axis of the receiver unit. The following section describes the procedure for aligning the receiver unit to maximize the signal of the analyzer. 3.3.2 Alignment of receiver unit

1. Remove the adapter ring (no.4 in Figure 3-1) from the receiver alignment & purging unit.

2. Disconnect the red laser alignment jig from the transmitter side and mount it on the receiver side. Locate the laser beam on the transmitter side. Loosen the adjustment screws shown in Figure 3-4 on the receiver unit purging flange and move it carefully from side to side and up and down to locate the laser beam in the transmitter hole. (You may need two persons.)

3. Having found the laser beam, move the beam to the center of the hole by carefully adjusting the adjustment screws on the receiver side. Lock the alignment by tightening the locking screws on the receiver side and check that the alignment has not changed. Having completed the previously described operations successfully, the transmitter and receiver should be re-mounted. Check the transmission reading on the transmitter unit LCD. Proceed to Section 3.4, where tuning for maximum transmission using a voltmeter is described.

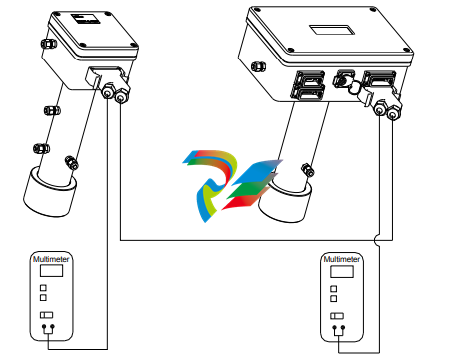

Tuning for maximum transmission Fine alignment of the transmitter and receiver unit to ensure maximum signal is accomplished by measuring the alignment voltage with a voltmeter and the supplied cable with miniature power plug. The alignment voltage varies from 0V at 0% transmission to −3V (typically) at 100% transmission. The alignment voltage is measured by connecting a voltmeter to the alignment jack on the transmitter unit. This jack is located on Phoenix connector of the transmitter-to-receiver cable as shown in Figure 3-6. A similar alignment jack is found on the receiver unit

The fine-tuning procedure is as follows:

Connect a voltmeter with floating inputs (battery powered) and measure the alignment voltage from the receiver unit.

2. Maximize the voltmeter reading by carefully adjusting the adjustment screws on the receiver side.

3. Connect a voltmeter with floating inputs (battery powered) and measure the alignment voltage from the transmitter unit.

4. Maximize the voltmeter reading by carefully adjusting the adjustment screws on the transmitter side.

5. Repeat steps 1-2 and 3-4 until no further improvements in voltmeter readings.

6. Tighten the locking screws and check that the alignment has not changed.

7. Disconnect the voltmeter Having completed the previously described operations successfully, the installation and process parameters need to be set correctly using a PC and the analyzer software to enable correct measurements. Setting of these parameters is explained in Section 4