ABBControlMaster CM10

Comprehensive display of process status

— Crystal-clear, full-color TFT display

— User-customizable Exceptionally easy to use

— Intuitive user interface and clear text prompts make installation, commissioning and operation quick and simple Scalable to match application requirements

— Comprehensive hardware and software options Flexible control functionality

— On / Off, time proportioning, analog PID and motorized valve control strategies Problem-solving capability

— Flexible functionality including math and logic providing power to solve application requirements Built to survive

— IP 66 and NEMA 4X environmental protection Flexible connectivity — Ethernet and MODBUS® communications

Overview The ControlMaster CM10 is a flexible, 1/8 DIN, universal PID process controller. Detailed process information is presented clearly on the CM10's full-color TFT display and an intuitive operator interface simplifies configuration and operation. Scalable in both hardware and software functionality, a CM10 can be specified easily to meet the needs of your application requirements. Flexible control functionality including on / off, time proportioning, analog PID, split output control and math & logic make the CM10 suitable for a wide range of process applications. Fully configurable via the easy-to-navigate front panel menus or PC configuration software, the CM10 can be commissioned rapidly and then tuned via the advanced autotune functionality. MODBUS and Ethernet communication options ensure easy integration into a control system.

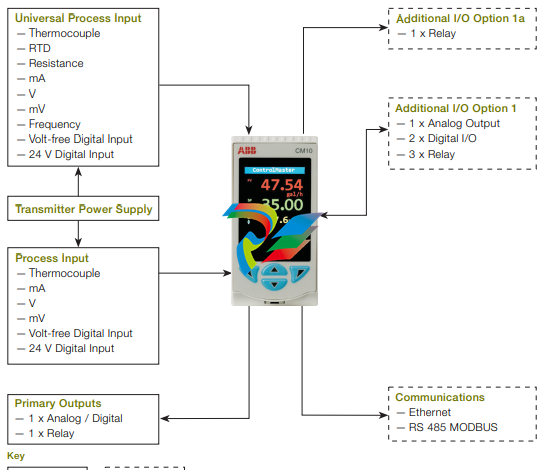

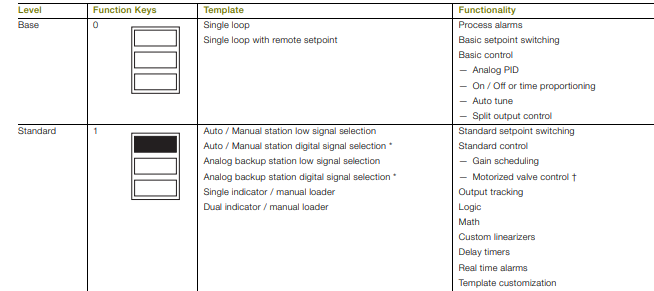

Scalable functionality The CM10 is scalable in terms of both hardware and software, enabling it to meet your application requirements. The basic CM10 meets the needs of a simple control loop. Additional templates and functionality can be enabled by adding a function key to the basic model as shown in Fig. 1, while retaining previous templates and functionality. For I/O builds, see also Ordering information on page 19

ControlMaster CM10 Universal process controller, 1/8 DIN 4 DS/CM10–EN Rev. K | ControlMaster CM10 | Universal process controller, 1/8 DIN Powerful operator display The CM10 features a full-color 5.5 cm (2.2 in.) display for displaying detailed process information to the user. Process details such as alarm messages and diagnostic information are displayed clearly in full text without the need for difficult-toread scrolling displays. Example of an operator page Automatic selection of standard display templates immediately makes best use of the CM10's display. Extensive customization features then enable the displayed information to be tailored to suit the process requirements. Diagnostics and alarm status display The diagnostics and alarm status display provides detailed information on any active alarm or diagnostic condition. The operator can see, at-a-glance, the status of any alarm condition present within the process. Additionally, diagnostic messages are presented clearly to the operator, enabling rapid notification and simple diagnosis of any critical instrument status condition. Historical information of diagnostic messages can also be viewed in the controller's diagnostic log.

Problem solving flexibility Extensive functionality is available to provide flexible problemsolving capability; making the CM10 much more than just a process controller. Process alarms 8 independent process alarms can monitor any analog signal within the CM10, enabling extensive process monitoring capability. Alarms can be used to drive physical outputs or soft-wired to other functions within the controller. Real-time alarms The 'alarm clock' functionality provided by the CM10's realtime alarms enables time-of-day decisions to be introduced into the controller's actions or specific functions to be triggered routinely at specified times. Delay timers Event sequencing is enabled through the use of the CM10's delay timers. A predetermined delay and output duration can be programmed into each delay timer and timers can be linked together. Custom linearizers The CM10 has 2 independent 20-point custom linearizers that can be applied to any analog signal within the controller. These linearizers can be used in applications such as level-to-volume conversion of a non-linear tank level or to accommodate special input signals or output devices.

Math 8 math blocks provide arithmetic, averaging, min. / max. hold, square root and signal switching functionality. Simple equations can be performed in a single math block or multiple math blocks can be nested together to construct complex equations. Signal switching 'multiplexer' math blocks switch between 2 analog signals based on a trigger signal. For example, a backup sensor could be selected automatically on failure of a primary sensor. Logic 8 comprehensive logic equations provide powerful interlock functionality. Inputs and outputs of the logic equations can be soft-wired to any digital signal within the controller to maximize flexibility