parkerVM600Mk2 A Second-Generation Architecture for a New Era

mixture is too lean. The ratio is

then adjusted (less lean) such that

the combustor is perpetually on

the verge of instability, but without

actually pulsating. In other words,

a precisely controlled balancing act

to maintain that tiny operational

zone existing between stable and

unstable combustion – a zone

where efficiency is highest and

NOx emissions lowest.

It turns out that monitoring these

pressure pulsations requires

sophisticated filtering and other

signal processing that is not unlike

the requirements of monitoring a

vibration signal – particularly those

from aeroderivative gas turbines

where accelerometers are used and

extraction of desired signal features

can be very demanding.

It was not surprising, then, that

gas turbine manufacturers turned

to vibration monitoring suppliers

to meet these needs. Vibro-meter

was among the first to rise to the

challenge and offer fully integrated

combustion dynamics monitoring

with the release of our VM600

platform and its 16-channel XMC16

module.

Indeed, the deep domain expertise

of Meggitt for supplying sensors

that can survive environmental

extremes meant that vibrometer could supply not only the

necessary monitoring system, but

the associated high-temperature

dynamic pressure sensors, able to

survive in one of the most extreme

of all machinery environments:

gas turbine combustors where

conditions at the measurement

locations can approach 700°C and

250 bar.

1. Zink, John C., “Progress

continues in gas turbine NOx

control” Power Engineering. May

1, 1996. Retrieved September 19,

2021.

2. Richards, G A, and Lee, G T. “Gas

turbine combustion instability”.

US Dept of Energy. September 1,

1996. Retrieved September 19,

2021.

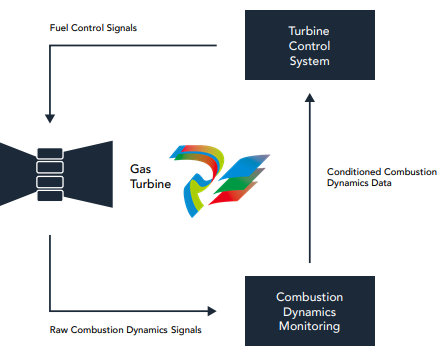

Combustion dynamics monitoring

is part of closed-loop control to

ensure that damaging pulsations

in low-NOx gas turbines do not

prematurely age or destroy the

combustor cans. The pulsations

occur because today’s lowNOx technologies rely on

inherently metastable combustion

conditions that burn fuel in the

leanest possible manner but can

produce an unstable flame if not

meticulously controlled

Full API 670 compliance

Within the petrochemical sector, the importance of American Petroleum

Institute standards for machinery and its associated instrumentation

cannot be overstated.

These standards are no longer considered best practice employed by the

cutting-edge few – they are so universally accepted that they are today

considered standard practice and thus widely embraced by the many.

Nowhere is this more true than with API Standard 67023 which defines the

necessary attributes of machinery protection systems.

The first edition of this standard was released in 1976 and has been so

successfully embraced that it has resulted in five successive revisions to

keep pace with industry’s changing needs: the 6th edition of the standard

is currently in preparation and is expected to be released by 2023.

Indeed, it provides such value that it has remained among the API’s bestselling standards in the more than 45 years since its introduction. Not

surprisingly, the VM600 was designed with full API 670 compliance in

mind, allowing customers in the oil & gas industries to employ the system

with the confidence that it rigorously adheres to the robust feature set

and functionality that multiple generations of users and manufacturers

have found important.

Indeed, the requirements of 670 are so well-recognized by practitioners

in all industries that it is not uncommon to find power generation

and other customers using it as the basis of their own purchasing

specifications – not just those in the petroleum industries.

3. API Standard 670 “Machinery Protection Systems”. American Petroleum

Institute. Washington, DC. November 2014.

Full API 670 compliance

Both first- and second-generation

VM600 platforms are fully

compliant with the 5th edition

of API 670. Additionally, we

participate on the API Task Force

that is currently preparing the 6th

edition to ensure we remain fully

compliant with and abreast of

industry changes as the standard

evolves.

Why a Second-Generation product?

With such a rich feature set and pedigree of innovation, it is natural to ask

why a second-generation platform was even necessary.

There are multiple reasons:

Cybersecurity

When the VM600 was originally

designed, the internet itself

was not even a decade old. The

idea that this global network

infrastructure would someday

become a remotely accessible

means to sabotage industrial

instruments and automation

systems wasn’t even part of

anyone’s thought process at the

time. But the intervening 22 years

have changed everything.

Today, cybersecurity is at the very

top of customer concerns. What

has also changed are the types

of customers concerned about

cybersecurity. For decades, the

most innovative and demanding

customers were largely in the

petroleum and oil & gas sectors.

They were often the ones with