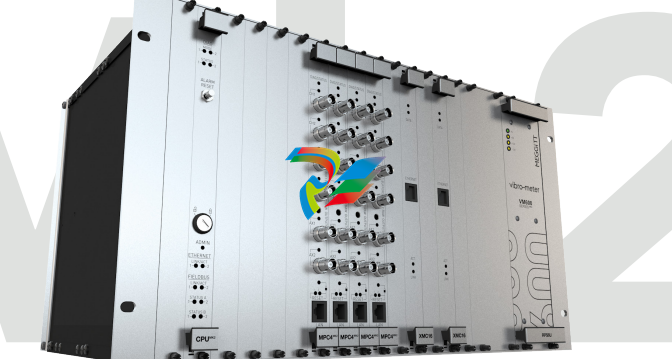

parkerVM600Mk2 A Second-Generation Architecture for a New Era

vibration condition monitoring,

respectively; we have simply

upgraded the faceplates for

aesthetic consistency with new

modules such as the MPC4Mk2

and CPUMMk2.

11. Mk2 modules are configured

using our VibroSight PROTECT

software; Mk1 modules are

configured using our MPSx

software. Also, MPC4Mk2 modules

can

only be paired with their associated

IOC4Mk2 input/output modules and

cannot use the existing IOC4T.

12. MPC4Mk2 modules retain the

ability to share input signals with

an associated XMV16 module,

but can also provide integrated

condition monitoring functionality

and thus entirely eliminate the

need for a separate condition

monitoring module for vibration

measurements.

Our second-generation VM600 platform retains all of the

innovation inherent in the first-generation product while

addressing evolving marketplace needs.

The Second-Generation VM600 retains the same chassis and power supplies, but delivers powerful new

modules with improved functionality and cybersecurity.

1 19” EIA chassis, 6U tall, 300mm deep, 21 slots (numbered 0-20).

2 CPUMMk2 Communications and rack control module; supports redundant media with communications with plant control and

automation platforms including PLCs, DCSs, turbine controllers, local displays, and more; supported protocols include Modbus TCP,

Modbus RTU*, Profibus DP, and Profinet*. Cybersecure design to meet IEC 62443.

3 Keylock provides an extra measure of physical security in addition to password-protected access to configuration changes.

4 MPC4Mk2 Universal vibration monitoring module provides 4 channels of dynamic signal inputs and 2 channels of speed/phase or DC

inputs; provides integrated protection and condition monitoring while delivering cybersecure performance to meet IEC 62443; up to

12 modules (72 channels) per rack.

5 The MPC4Mk2 is capable of specialized measurements such as generator air gap on hydroelectric units, combustion monitoring on

gas turbines

6 SIL 2 version of MPC4Mk2 modules. Five on-board relays allow alarm and module fault (OK) status annunciation, suitable for autoshutdown applications meeting SIL 2.

7 XMV16 module can be used for condition monitoring-only applications where protection is not required; allows 16 channels of highperformance condition monitoring in a single rack slot. Ideal for balance-of-plant assets, small hydro units where protection is not

required, or for adding condition monitoring to existing third-party protection systems.

8 XMC16 module provides robust gas turbine combustion dynamics monitoring in the same chassis as vibration protection and

condition monitoring.

9 RLC16Mk2 relay expansion module provides 16 additional relays to augment the 5 relays on board each MPC4Mk2 module.

10 Proprietary ethernet communications provide all dynamic and other rack signals to VibroSight software for archival, analysis, and

visualization.

11 Simplex or redundant power supplies deliver all required power for rack modules and connected sensors.

s no longer necessary to

use MPC4 cards for protection

and separate XMV1613 cards

for condition monitoring. The

functionality of the XMV16 is now

built-in to the new MPC4Mk2 cards.

Not only does this eliminate the

cost of unnecessarily redundant

hardware, it eliminates the

dissimilar-data issues inherent in

two separate signal processing

paths and alarm processing paths

that were noted in the section on

integration. Condition monitoring

can now focus on supplementary

signal processing and alarming

to augment the basic protection

system measurements – not recreating them.

This also speeds the configuration

process because the configuration

elements that are common to

both the protection and condition

monitoring systems no longer need

to be duplicated. Configuration

in the condition monitoring

environment thus adds to the basic

protection configuration. Alarms

and data are perfectly synchronized

between the two environments

and the condition monitoring

environment can be used to

visualize everything while allowing

an additional layer of alarming

for earlier warning on any desired

parameter – whether a parameter

from the underlying protection

system or a parameter created only

for use in the condition monitoring

environment.

13. When a VM600 rack is used

purely for condition monitoring,

such as when connected to a

separate machinery protection

system from another supplier, the

XMV16 module provides costeffective condition monitoring

functionality for 16 channels in a

single rack slot. MPC4Mk2 modules

and their associated machinery

protection functions are not

required.

The new MPC4Mk2 module (left) and

its companion I/O module (right)

provide integrated protection and

condition monitoring, eliminating

the need for a separate XMV16

module.

And while this integration makes

for a more powerful and efficient

VM600 platform, we have achieved

this without compromising

cybersecurity, as discussed next.

The new MPC4Mk2 module provides integrated condition monitoring functionality identical to that of a separate

.png)

.png)

.png)