parkerVM600Mk2 A Second-Generation Architecture for a New Era

VM600 First-Generation:

One module does it all

When vibro-meter introduced

the VM600 architecture in 2000,

it represented a dramatic leap

forward that sent shockwaves

through the industry with numerous

innovative features.

The most notable of these was

the simplicity of an architecture

that used a single card type – the

MPC4 – to address all channel

types except temperature. Prior

architectures, and the prevailing

model embraced by every other

leading manufacturer of the time,

was a reliance on a large diversity

of module types. For example, one

well-known manufacturer required

more than 20 different module

types in their system to achieve

the full complement of all available

functionality.

Compounding the issue, each

monitor module type had as many

as 3 different corresponding I/O

module variations. The spare

parts implications were significant

– along with the widely varying

costs of each module depending

on the channel types supported.

It was a complex architecture with

a complex diversity of modules, a

complex pricing structure, and a

complex spare parts burden.

In contrast, the VM600 required

only 4 basic card types (power,

communications, temperature, and

universally configurable vibration)

for comprehensive machinery

protection, each with only a single

type of corresponding I/O module.

In a word, the system was uniquely

simple – without sacrificing

functionality. It also introduced

the concept of combining speed

/ phase reference measurements

on a single module as auxiliary

channels.

This allowed four channels of

vibration and two channels of

tachometer and/or phase reference

to be addressed in a single rack

slot via the MPC4 (Machine

Protection Card – 4 channel).

In fact, it perhaps would have been

better named “MPC4+2” for this

very reason

.

In addition, 4 relays were included

on each MPC4, turning a single

module into a fully self-contained

monitor with all required protective

functions. Hence, the slogan “one

module does it all” aptly described

the workhorse of the system: the

MPC4 module that provided true

“universal” programmability for all

required vibration channel types

and sensors.

The VM600 was introduced in

2000 and required only 4 basic

module types for comprehensive

machinery protection functionality:

power, temperature, vibration, and

communications.

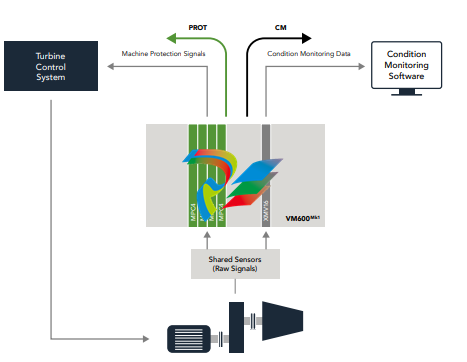

Segregated condition monitoring

Another key innovation of the

first-generation architecture was

entirely segregated, 16-channel

condition monitoring (CM)

modules that ensured machinery

protective functions could never

be compromised by failures in the

condition monitoring hardware,

yet resided in the same rack

chassis and could share input

signals with the MPC4 protective

modules – or use entirely separate

inputs if desired. Two CM module

types were available – one for

vibration (XMV16) and one for

gas turbine combustion dynamics

(XMC16). Other manufacturer’s

platforms of the era used highly

integrated condition monitoring

that co-mingled protective and

CM functions, resulting in a level

of integration that amplified rather

than attenuated vulnerabilities.

The VM600’s first-generation

architecture physically separated

condition monitoring from

protection by using separate

modules – the MPC4Mk1 for

protection and the XMV16 for

condition monitoring. A variant

of the XMV16 (the XMC16) was

used for combustion dynamics

monitoring on low-NOx gas

turbines.

As gas turbine firing temperatures

increased in the 70s, 80s, and 90s

to achieve greater efficiencies,

these efficiencies came at the

expense of increased NOx

emissions. It was not long before

environmental concerns demanded

these increased NOx emissions

be reduced, and new combustor

technology emerged as a result,

referred to as Dry Low NOx

(DLN) or Dry Low Emissions (DLE)

designs1

.

Although these designs did indeed

reduce NOx emissions, they

entailed so-called “metastable”

combustion conditions that could

impose extremely damaging

dynamic pressure pulsation forces

on the combustor2

. If not very

carefully monitored and controlled,

combustor life could be severely

degraded.

It was out of this fundamental

need that gas turbine combustor

monitoring emerged.

The concept is quite simple: adjust

the fuel/air mixture to be as lean

as possible, but not so lean as

to introduce an unstable flame

and the accompanying dynamic

pressure pulsations that will

prematurely age (or destroy) the

combustor.

Using highly specialized hightemperature pressure sensors, the

pressure inside each combustor

is monitored for the presence of

these damaging pulsations and the

fuel/air ratio is continually adjusted

using a closed feedback loop

between the dynamic pressure

sensing system and the turbine

control system where the fuel/air

mixture is adjusted.

When pulsations are detected,

the flame is unstable and the

.png)

.png)

.png)