schneiderUniversal Instruction Manual I/A Series® Pressure Transmitters Models IAP10, IAP20, IGP10, IGP20, IGP25 and IGP50, IDP10, IDP25, IDP50 Configuration, Calibration, Installation, and Operation

eliminate the position zero effect.

Mechanical Installation

Differential Pressure Transmitter

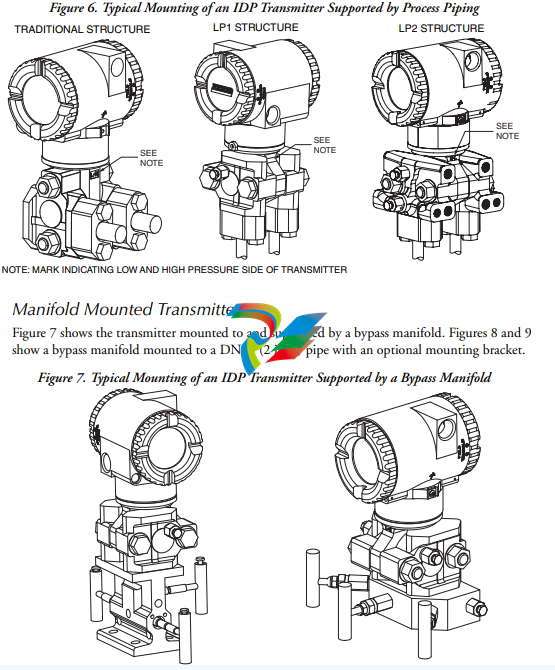

The IDP10, IDP25, and IDP50 differential pressure transmitters can be supported by the process

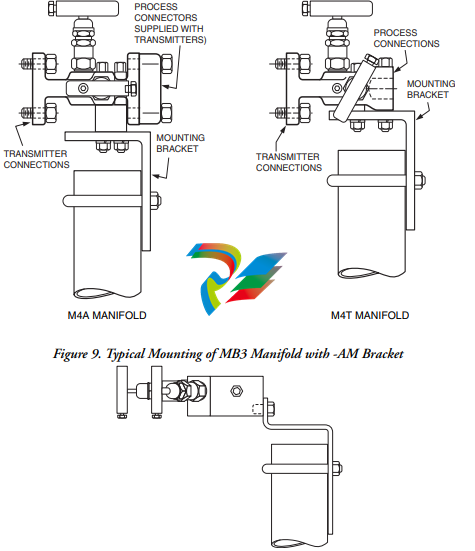

piping (Figure 6), on a bypass manifold (Figures 7 through 10), or mounted to a vertical or

horizontal pipe or surface using an optional mounting bracket (Figures 11 through 16). For

dimensional information, refer to DP 020-446.

NOTE

1. The IDP25 and IDP50 transmitters are only available in the Traditional Structure

at this time.

2. If the transmitter is not installed in the vertical position, readjust zero output to

eliminate the position zero effect.

3. When pvdf inserts (structure codes 78/79) are used, the process connection must

be made directly to the pvdf inserts in the Hi and Lo side process covers.

4. The transmitter should be mounted so that any moisture condensing or draining

into the field wiring compartment can exit through one of the two threaded

conduit connections.

Process-Mounted Transmitter

Figure 6 shows the transmitter mounted to and supported by the process piping

Figure 8. Typical Mounting of M4A and M4T Manifold with -AM Bracket

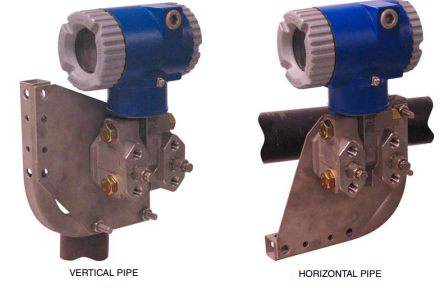

Pipe- or Surface-Mounted Transmitter

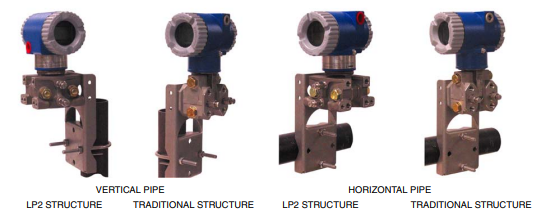

To mount the transmitter to a pipe or surface, use the Standard Mounting Bracket Set (Model

Code Option -M1 or -M2) or Universal Bracket Mounting Set (Model Code Option -M3).

Standard Mounting Bracket

The transmitter (with either traditional or LP2 low-profile structures) can be mounted to a

vertical or horizontal, DN 50 or 2-in pipe using a standard bracket. See Figure 11 for details and

Figure 12 for examples of different situations. Secure the mounting bracket to the transmitter

using the four screws provided. Mount the bracket to the pipe. To mount to a horizontal pipe,

turn the U-bolt 90° from the position shown in Figure 11. The mounting bracket can also be

used for wall mounting by securing the bracket to a wall using the U-bolt mounting holes.

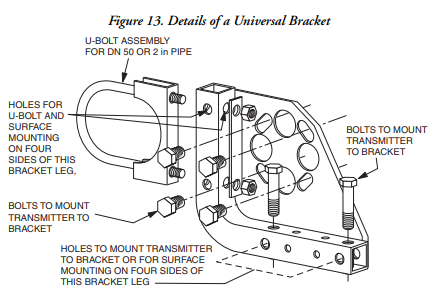

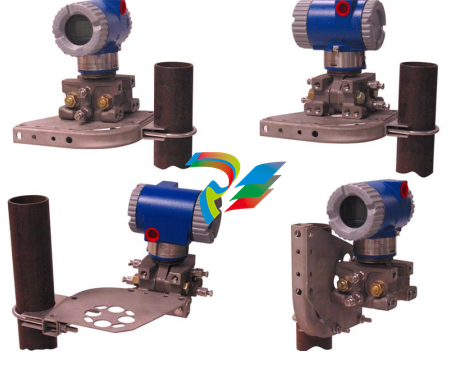

Universal Mounting Bracket

The transmitter (with either traditional or LP2 low-profile structure) can be mounted in a myriad

of positions to a vertical or horizontal, DN 50 or 2-in pipe using a universal bracket. See

Figure 13 for details of a universal bracket and Figure 14 through Figure 16 for examples of

different mounting situations. Secure the mounting bracket to the transmitter using the two long

or four short screws provided. Mount the bracket to the pipe. The mounting bracket can also be

used for wall mounting by securing the bracket to a wall using the U-bolt mounting holes.

Figure 14. Mounting a Transmitter with Traditional Structure Using a Universal Bracket

Figure 15. Vertical Pipe Mounting a Transmitter with LP2 Structure Using a Universal Bracket

.png)

.png)

.png)