schneiderUniversal Instruction Manual I/A Series® Pressure Transmitters Models IAP10, IAP20, IGP10, IGP20, IGP25 and IGP50, IDP10, IDP25, IDP50 Configuration, Calibration, Installation, and Operation

Transmitters with ATEX flameproof certification. Ensure that the transmitter is operated within

this range.

The sensor body operating temperature limits are determined by the sensor fill fluid. The cover

material, sensor diaphragm material and fill fluid are specified by two characters in the model

code on the data plate. See Item A on the example shown in Figure 1. Also see Table 5 and

Table 6 to interpret this part of the code and Table 7 to determine the sensor body temperature

limits. In the example IDP10-D12A21E-A3, the number 12 identifies the fill fluid in Table 5 as

silicone. Table 7 identifies silicone as having temperature limits of -46 and +121°C (-50 and

+250°F).

The diaphragm material code is found in the pressure seal model number which is located on the

pressure seal. See following example:

The housing material is 316 ss.

The gasket is provided by the user.

Pressure Seals PSSCT

The housing material is 316 ss.

The diaphragm material is 316L ss.

The gasket is provided by the user.

Pressure Seals PSSSR and PSSST

The housing material is 316 ss.

The diaphragm material is 316L ss.

The gasket material is EPDM.

Warnings

General Warning

! WARNING

1. Transmitters must be installed to meet all applicable local installation regulations,

such as hazardous location requirements, electrical wiring codes, and mechanical

piping codes. Persons involved in the installation must be trained in these code

requirements to ensure that the installation takes maximum advantage of the safety

features designed into the transmitter.

2. A plug is supplied with each transmitter with 1/2 NPT conduit connection. It is

intended to provide moisture ingress protection of the unused housing conduit entry.

The plug must be wrench tight to achieve this level of protection. Thread sealant is

required. Explosion-proof applications may require a certified plug.

Housings with M20 / PG 13.5 threaded conduit connections are provided with an

ATEX certified plug. Thread sealant is required to provide moisture ingress

protection.

ATEX Warnings

! WARNING

Apparatus marked as Category 1 equipment and used in hazardous areas requiring

this category must be installed in such a way that, even in the event of rare incidents,

the versions with an aluminum alloy enclosure can not be an ignition source due to

impact and friction

Install ATEX certified transmitters in accordance with the requirements of standard

EN 60079-14.

! WARNING

To install a transmitter labeled with multiple approvals, select and permanently mark

the certification label in the tick block to distinguish the installed approval type from

the unused approval types. Once installed, the transmitter cannot be reinstalled using

any other approval type. Not following these instructions will jeopardize explosion

safety.

On IGPxx and IAPxx Transmitters with IECEx certification, the maximum constructional gap

(Ic) is less than that required by IEC 60079-1:2003 as detailed in the table below:

Explosionproof/Flameproof and Enclosure Warning

! WARNING

1. To prevent possible explosion and to maintain explosionproof/flameproof and dustignitionproof protection, plug unused openings with a certified metal pipe plug. For

1/2 NPT connections, both the plug and conduit must be engaged a minimum of five

full threads. For M20 and PG 13.5 connections, the certified plug provided and the

conduit must be engaged a minimum of seven full threads.

2. The threaded housing covers must be installed. Turn covers to seat O-ring into the

housing and then continue to hand tighten until the cover contacts the housing

metal-to-metal.

3. If the electronics housing is removed for any reason, it must be hand tightened

fully. Then engage the set screw until it bottoms out and back it off 1/8th turn. Fill

the set screw recess with red lacquer (Foxboro Part Number X0180GS or equivalent).

The housing then may be rotated up to one full turn in a counterclockwise direction

for optimum access to adjustments.

Intrinsically Safe and Type n Warning

! WARNING

Since live maintenance is not specified, to prevent ignition of flammable atmospheres,

disconnect power before servicing unless the area is certified to be nonhazardous.

Type n Warning

! WARNING

On transmitters certified for ATEX protection n, CSA Class I, Division 2, or FM

nonincendive for Class I, Division 2, the threaded housing covers must be installed.

Pressure Warnings

! WARNING

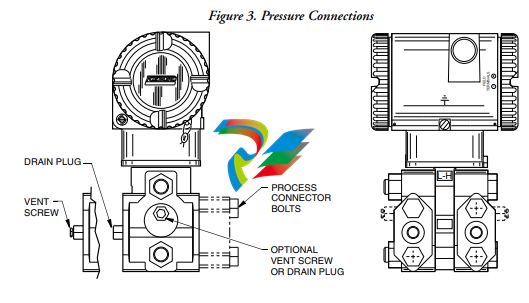

When installing your transmitter, tighten process connector bolts to a torque of

61 N•m (45 ft•lb) and drain plugs and optional vent screws to 20 N•m (15 ft•lb). See

Figure 3.

If a sensor is replaced or process covers are rotated for venting, replace the gaskets and

torque cover bolts (see Figures 4 and 5) to 100 N•m (75 ft•lb) in several even

increments. Torque values are 66 N•m (50 ft•lb) when optional 316 ss bolts are

specified (option B1). A pressure test is required. Perform a hydrostatic test with a

liquid following proper hydrostatic test procedures. Pressure test the process cover

.png)

.png)

.png)