schneiderUniversal Instruction Manual I/A Series® Pressure Transmitters Models IAP10, IAP20, IGP10, IGP20, IGP25 and IGP50, IDP10, IDP25, IDP50 Configuration, Calibration, Installation, and Operation

This Universal Instruction Manual is designed to provide the user with a single, concise, easy-touse manual that covers the key points needed for configuration, calibration, installation, and

operation of I/A Series Pressure Transmitters.

It covers all models of single variable pressure transmitters in the I/A Series family, including

absolute, gauge, and differential pressure transmitters, with FoxCom, HART, FOUNDATION

Fieldbus, or analog output electronics.

This universal manual, along with a DVD containing detailed information, is provided free of

charge with every I/A Series Pressure Transmitter, unless the purchaser requests that these two

items be omitted.

For additional detailed information about each model, including dimensional prints, parts lists,

and more detailed instructions, please refer to the standard DVD supplied or the optional paper

instruction book that is available for each model in the line.

♦ Standard Documentation Shipped with every I/A Series Pressure Transmitter

♦ A brief “Getting Started” Pocket-Sized Bulletin

♦ This Universal Instruction Manual

♦ A DVD that contains the complete documentation set for I/A Series Pressure

Transmitters

♦ When Optional Feature K1 is specified in the Model Code when the transmitter is

ordered:

A brief “Getting Started” Pocket-Sized Bulletin only is supplied

Optional Feature K1 is offered for those users who want to omit the documentation

shipped with every transmitter. This may be specified when multiple identical

transmitters are ordered and the user does not want multiple sets of documentation.

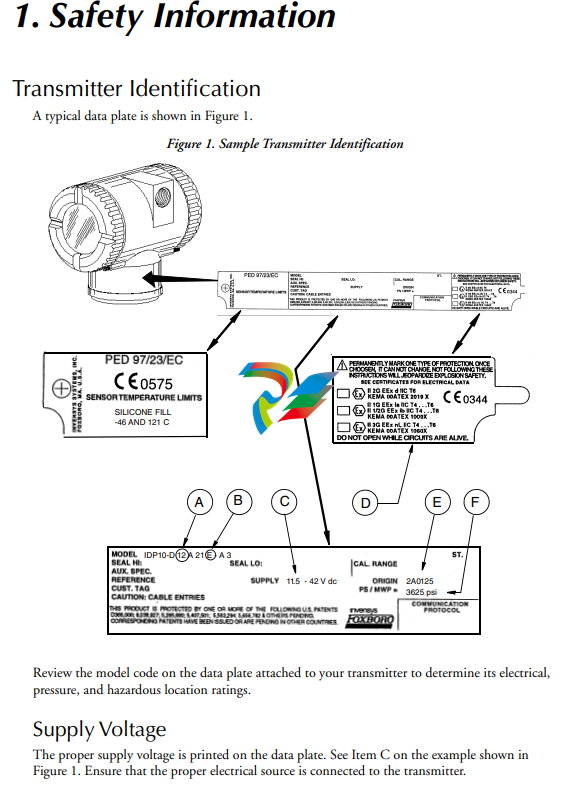

Electrical Certification Rating

The electrical safety design code is printed on the data plate as part of the model code. See Item B

on the example shown in Figure 1. See the "Product Safety Specifications" section of the

instruction pertaining to your instrument on the enclosed DVD to identify this code. The type of

protection is also marked on the data plate. See Item D on the example shown in Figure 1.

PED Certification

The PED (Harmonized Pressure Equipment Directive for the European Community)

certification is offered only with transmitters ordered with ATEX Electrical Safety Design Code

selections. Transmitters with PED certification have a CE marking on the data plate that also

carries the PED number 0496.

Pressure Rating

The maximum working pressure (PS or MWP) for the transmitter is printed on the data plate.

See Item F on the example shown in Figure 1.

The data plate of flanged level transmitters and transmitters with flanged pressure seals are

stamped with the MWP if the transmitter pressure range is the limiting factor. It is stamped

“Flange Rate” if the flange rating is the limiting factor. The MWP of the flanged seal is stamped

on the seal data plate. See Figure 2.

Figure 2. Sample Seal Data Plate

When using transmitters with threaded, in-line saddle weld, or sanitary pressure seals, compare

the MWP of the transmitter on the transmitter data plate and the MWP of the seals on the seals

data plates and use the lesser value as the system MWP.

The MWP on the seal data plates may not be given at your process temperature. Use the

following information and industry standards as required to determine the actual pressure limits

for your application.

MODEL CODE: PSFPS-A2S0E313B MWP: 275 psig at 100°F

NOTICE: BREAKING CONNECTIONS VOIDS WARRANTY

BE SURE FILL FLUID CAN MIX SAFELY WITH PROCESS HIGH SIDE SEAL

HIGH SIDE FLUID, DC200, 10 cSt SILICONE TEMP RANGE -40 TO +450°F

PROCESS WETTED MATERIAL 316 SS

essure Seal PSFLT

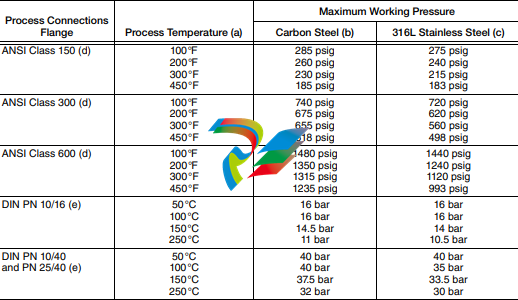

Table 1. Pressure Seal PSFLT Pressure Limits

a. Flange temperature/pressure ratings only; seal temperature ratings may be lower; refer to Table 8

b. ASME/ANSI Material Group 1.1; linear interpolation acceptable

c. ASME/ANSI Material Group 2.2; linear interpolation acceptable

d. ANSI flanges per ASME/ANSI B16.5-1988.

e. DIN flanges per BS4504.

Pressure Seals PSFPS and PSFES

Table 2. Pressure Seal PSFPS and PSFES Pressure Limits

Pressure Seals PSSCR and PSSCT

The maximum working pressure of the seal process connection varies with the clamping device

used. Refer to Tri-Clover Tri-Clamp standards to determine the pressure limits of the clamping

system that you are using.

PSSSR and PSSST (Sanitary Tank Spud) Seals

The maximum working pressure of mini tank spud seal is 1.55 MPa at 120°C (225 psi at 250°F).

That of the standard tank spud seal is 1.38 MPa at 120°C (200 psi at 250°F).

Origin Code

The origin code identifies the area of manufacture and the year and week of manufacture. See

Item E on the example shown in Figure 1. In the example, 2A means the product was

manufactured in the Measurement and Instrument Division, 01 identifies the year of

manufacture as 2001, and 25, the week of manufacture in that year.

Operating Temperature Limits

The operating temperature limits of the electronics are -40°C and +85°C (-40°F and +185°F).

The limits are -40°C and +75°C (-40°F and +167°F) for IAP10, IGP10, IGP25, and IGP50

.png)

.png)

.png)