EMERSONWestinghouse Nuclear Automation

Westinghouse Control Systems Westinghouse Control Systems

● Westinghouse uses Ovation

® Distributed Control

System as highly reliable platform for non-safety

cont l f ti i PWR BWR & VVER trol functions in PWRs, BWRs

& VVER

s

– Eliminate plant trips

– Reduce or eliminate critical path time

– Eliminate single-point vulnerability

– Eliminate hardware calibration time

– Provide advanced diagnostics down to point level

– U t d d d t ll i &h d Use s

tan

dar

d an

d proven con

trol logic

&

har

dware

configurations

– Reduce operator burden and challenges

– Common interface across control systems Common interface across control systems

applications and platform

– Advanced platform that supports the latest

technolo

gies and common desi

gns with AP1000

Ovation

® Well Suited For Nuclear Well Suited For Nuclear

• Designed for the power industry with Nuclear attributes

• I t t Pl t O t Si l ti S l ti In

tegra

tes Plan

t

Opera

tor Simulation

S

olution

• Integrates System Security Model

S

y yp stem functions defined b

y roles & res

ponsibilities

User actions defined down to point level

• Alarm System

Eight alarm levels (four high & four low) Eight alarm levels (four high

& four low)

Alarm cutout

Modal alarming based on plant conditions

• Controller Application Software is in a Drawing Sheet

format using SAMA symbols

• Scalable & Integrated Cyber security solution

3

Scalable

& Integrated Cyber security solution

Ovation

® Applications in Nuclear

Control Applications

(

Analo

g/Pneumatic/Di

gital

)

Ovation

® Applications in Nuclear

pp

( g g)

NSSS Controls – Advanced Feedwater Control, Pressurizer

Level & Pressure, Chemical Volume Control Systems, Rx

Temperature, Steam Dump, Rod Control Demand, Reactor

Water Level, Reactor Recirculation, Reactor Pressure

BOP Controls BOP Controls

– Moisture Separator Re Moisture Separator Re

-heater Heater drains heater, Heater drains,

Drain tanks, Waste Processing, Sampling Systems, etc.

Main Turbine and Feed Pum

p control &

p y rotection s

ystems

including electro hydraulics

Vibration Monitoring System (CSI-6500 or Bently Nevada)

Ovation

® Applications in Nuclear (cont)

Control Applications

(Analog/Pneumatic/Digital cont

)

Ovation

® Applications in Nuclear (cont)

Control Applications

(Analog/Pneumatic/Digital cont

)

Rod Control Logic Comtrol

Rod Position Indication System Rod Position Indication System

Bus technologies (Profibus and Foundation Fieldbus)

Wireless Technologies – monitoring applications

Flux Mapping Systems and Traverse Incore

Generator Monitoring and Protection

Automatic Voltage Regulator – Alterrex, WTA

Ovation

® Applications in Nuclear (cont)

Information System Applications

Sft P t Di l S t (SPDS)

Ovation

® Applications in Nuclear (cont)

S

a

f

e

t

y

Parame

t

e

r Display

Sys

tems (SPDS)

Smart Alarm systems (Westinghouse Product)

Plant Computer systems including Nuclear Application Programs Plant Computer systems including Nuclear Application Programs

Plant Simulators

Stimulated Solutions

– hardware based

Simulated Solutions – manually coded application software

Emulated Solutions – automatically generated software running

on virtual machines

Westinghouse Ovation Westinghouse Ovation

® Projects

U.S. Plants

● AP1000™- Vo

gtle 3&4, VC Summer 2&3

(In Process MCR, SIM, all non-safety including FWCS )

● Duke Energy – Catawba 1&2 (NSSS/FWCS, SIM)

● Duke Energy – McGuire 1&2 (NSSS/ FWCS, FPCS, MTS,SIM)

● Exelon

– Byron 1&2; Braidwood 1&2 (TCPS TGTMS MSR MTS SIM) Byron 1&2; Braidwood 1&2 (TCPS, TGTMS, MSR, MTS, SIM)

● Exelon – Clinton (RWLCS, SIM) in process

● FP&L – St. Lucie (TCPS, SIM)

● Hope Creek (SPDS, SIM)

● P i t B h (PCS SIM) P

oin

t

Beac

h (PCS, SIM)

● SCE – San Onofre 2&3 (TCS, FWCS, FPCPS, CVCS, SIM)

● South Texas 1&2 (PCS, AS, SIM)

● South Texas 3&4 ABWR ( ) In Process; MCR, All BOP )

● Surry 1&2 (PCS, SIM)

● SNC – Farley 1&2 (In Process, TCPS, MSR, SIM)

● SNC – Vogtle 1&2 (FWCS, SIM) delivered – not installed

● Wolf Creek

- (In Process TCPS FPCPS BOP MTS SIM)

8

Wolf Creek

- (In Process, TCPS, FPCPS, BOP, MTS, SIM)

Westinghouse Ovation Westinghouse Ovation

® Projects

Foreign Plants

● AP1000™**

– China 4 Units China

4 Units (In process; (In process; Haiyang Haiyang 1&2, Sanmen 1&2 MCR 1&2, MCR,

all non-safety, including FWCS, SIM)

● Almaraz 1&2 – Spain (TCS,NSSS/FWCS, FP, BOP, MTS, SIM) PCS in Process

● Angra – Brazil (AVR) FWCS in process

● Asco1&2

– Spain (LEFM) PCS, NSSS/FWCS & TCPS in process:

● Kozloduy 5&6 – Bulgaria (NSSS/FWCS, BOP, TCPS, PCS, SIM)

● Koeberg 1&2 – South Africa (PCS, SIM)

● Krsko

– Slovenia Slovenia (TCPS SIM (TCPS, SIM)

● Leningrad 3&4 RBMK; PCS

● Ringhals 2 – Sweden (MCR, all non-safety including FWCS, SIM)

●

Q sa in

s

h

a

n 3&4

–

C a hin

a ( CS) T

● Shin Kori 1&2 – Korea (MCR, NSSS/FWCS, BOP, SIM)

● Shin Kori 3&4** – Korea (MCR, all non-safety including FWCS, SIM)

● Shin Wolsong 1&2** – Korea (MCR, all non-safety including FWCS, SIM)

9

● South Ukraine Unit 3&4

– Ukraine (PCS, SIM)

Westinghouse Ovation Westinghouse Ovation

® Projects

Foreign Plants (cont)

● Vandellos 2

–

S

p( , , , ain

(PCS, TCPS, MSR, TGTMS, , ,) MTS, SWS, SIM

)

FPCPS & NSSS/FWCS in process

● Yonggwang 1&2 – Korea (TCPS, MSR, MTS, SIM)

● Zaporozhe VVER1000 – Russia Multi-Unit SPDS

Legend:

• **- New Plant

• AS - Annuciators System

• ATS – Automatic Turbine Startup

• MTS – Maintenance Training System

• MSR – Moisture Separator Controls

• NSSS - Nuclear Steam Supply System

• AVR

–

Automatic Voltage Regulator PCS Plant Comp ter S stem

• BOP – Balance of Plant

• CVCS – Chemical Volume Control

System

• FPCS Feedpump Control System

• PCS

– Plant Comp

uter

S

ystem

• RWLCS – Reactor Water Level Control

System

• SIM – Plant Simulator

• FPCS

– Feedpump Control System • SPDS

– Safety Parameter Display System

• FPCPS – Feedpump Control and

Protection System

• FWCS – Feedwater Control System

• Leadin

g Ed

ge Flow Meter - LEFM

SPDS Safety Parameter Display System

• SWS – Service Water System

• TCS – Turbine Control System

• TCPS – Turbine Control Protection System

• TGTMS – Turbine Generator Temperature

10

g g

• MCR - Main Control Room Monitoring System

Westinghouse WDPF Projects Westinghouse WDPF Projects

● Ginna – (FWCS, SIM)

● A 1&2 sco

– S i (TCS NSSS/ Spain (TCS,NSSS/FWCS, FP, MTS, SIM)

● Prarie Island 1&2 – (FWCS, SIM, MTS)

● Ringhals Ringhals 3&4

– Sweden (MCR NSSS/ (MCR, NSSS/FWCS, MTS SIM) MTS, SIM)

● Salem 1&2 – (FWCS, PCS, SIM, MTS)

● Sizewell B

– En

gland

( , MCR all non-safet

y includin

g FWCS,

SIM)

● Temelin 1&2– Korea (MCR, all non-safety including FWCS,

SIM

)

Westinghouse Control Systems Westinghouse Control Systems

● All control systems undergo a rigorous design - validation

process

● Extensive validation testing is performed in hierarchical levels

where each level builds upon the previous

● At the heart of this process is the Software In Loop (SWIL)

Validation testing which utilizes a plant Validation testing which utilizes

a plant

-specific engineering specific engineering

model to close the process loop

– The Pressurized Water Reactors (PWR’s) SWIL plant models

have been develo

p y ed and refined with over 25

years of

experience with successful results

– These models have been validated against multiple plants

with various types of steam generators

– Th SWIL lid ti t ti th t fi ld t i d The SWIL valid

ation

testing ensures th

a

t no fi

eld

tuning an

d

system modifications are needed during plant startup &

evolution to full power

Control System Control System Design Process Design Process

● Design Input Data Collection (Baseline Data)

● Design

– Functional Diagrams/Functional Requirements

– Database, Control Logic Sheet & Graphics

● Modeling & Analysis

– Advanced C S ( CS ) Control

Simulation Language Model

(

ACS

L

)

(plant specific model configured for given application)

– Setpoints List

● Control System Software Testing Control System Software Testing

– Software-in-Loop (SWIL) Test , Results & Report

– Phased Factory Acceptance Tests (FAT)

● Simulator

● St t ar

tup

– Site Acceptance Test Procedure/Guidelines

– Power Ascension Test (PAT) Guideline

– PAT On

-site startup support

Design Input Data Collection

Key Sources Key Sources

● System Information

– Characteristics of I&C Systems being

• Organizational Interfaces:

- Project Manager replaced

– Design basis

(existing & upgraded)

● Process Information

Project Manager

- Project Engineers

- Design/Integration Engineers

● Process Information

- Startup Engineers

– Characteristics of Field Devices

– Sensors & Control Devices

(Pumps, Valves, etc)

Startup Engineers

- System Engineers (Plant

Systems, Subject Matter

Ex

perts) – Characteristics of

Process/Components

– SG/Vessel, Piping, other

NSSS/BOP com

ponents

p )

- Component Engineers

(SG/Vessel, Valves, Pumps)

p - I&C Engineers

– Characteristics of Operation & Plant

Performance

– Statepoints, procedures, historical

data (plant computer)

- Operations

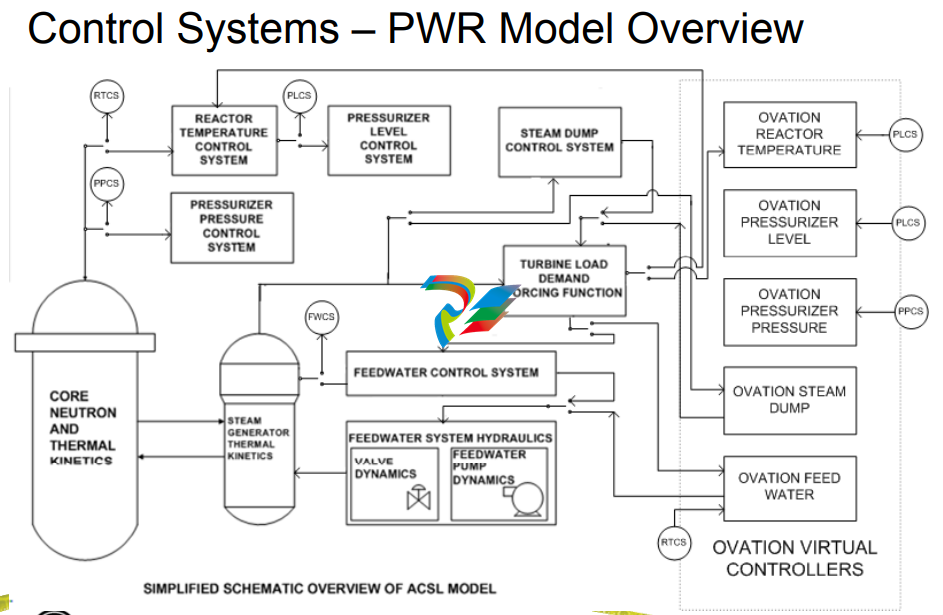

ACSL Model Configuration Overview ACSL Model Configuration Overview

● Design/operational data collected from plant, reviewed for

accuracy, p , y ( p ) com

pleteness, consistenc

y

(i.e. no discre

pancies

)

● Configuration data loaded into ACSL based plant model

● The plant-specific ACSL plant model is tied into ACSL based

control system models transient cases are evaluated control system models transient cases are evaluated

● Adjustments are made until subject matter expert (SME) is

confident that the plant model and control system models are

respondi tl ng correctl

y

● SME peer check is also performed to ensure suitability for use

● Once model review & res

p p,p onse checks are com

plete, set

point

sensitivity tests are performed

● ACSL based control system model is disconnected and Ovation

control system is switched in; transients cases are re

-performed

16

control system is switched in; transients cases are re performed

and evaluated

Setpoint Determination Setpoint Determination

● Dynamic transient analysis using high-fidelity ACSL model of

p g rocess runnin

g faster than real time

– Steam Generators or Reactor Vessel

– Steam Dump or Steam Bypass – Reactor Pressure Regulation

– Feed System Feed System

– Steam System

– NSSS (core)

● Evaluation response over the full range of operation and

operational transient conditions

– Normal Operation

– Contingency Operations

● Provides high confidence set of initial tunings

● Pr

ovides

a basis for v

alidati

on

of desig

n

Feed Water Control Design Overview

- Example

● S/G Model Description Example

– Nodes of S/G Model

Feed Water Control Design Overview Example

Nodes of S/G Model

– Primary side tubes

– Secondary side tube bundle area (inside of wrapper)

– Riser section (from bundle exit through primary separators) Riser section (from bundle exit through primary separators)

– Upper downcomer (generally downcomer area from start of transition cone to top of primary separators)

– Lower downcomer (straight cylindrical portion of downcomer belo transition cone) below transition cone)

– Steam dome (region above top of risers or primary separators)

– Separate mass/energy balances for exit properties

– Momentum balance performed to calculate change in

various section flow rates

Feed Water Control Design Overview Feed Water Control Design Overview

- Example Example

● Proven Validation Approach

– SWIL (

S

oft

ware In

Loop) l d l lid ti t ti ) close

d loop valid

ation

testing

with plant specific model ensures realistic plant

operational response

–

ACSL Models validated for various SG’s and now

Reactor Vessels (BWR)

Westinghouse

B&W Canada (5 Units)

AREVA (5 Units)

C b ti E i i (4 U it ) Com

bustion

Eng

ineering (4

U

nits)

GE BWR 6 Reactor Vessel – Clinton and River Bend

Feed Water Control Design Overview Feed Water Control Design Overview

- Example Example

● Proven Control Application

– SWIL l d SWIL close

d

-l l oop, real-ti t ti id lid ti time

testing provides valid

ation,

allows integration test of graphics, alarms and controls with

plant operators before system is manufactured

Setpoints verified for operational transients

(determined previously with ACSL control system

models)

Dynamic set points (Gain, Integral & Derivative) for PID

are carefully chosen

For responsiveness to transients For responsiveness to transients

For near steady state conditions

Results in no tuning during plant startup

Software In Loop (SWIL) Software In Loop (SWIL)

● Upon completion of setpoint analyses, the ACSL plantspecific control model is switched to Ovation virtual

controllers for real-time, closed-loop validation testing

● Verifies delivered system contains the proper setpoints and

control logic as presented in the functional requirement

documents

● Test performed by Subject Matter Expert along with detailed

checks of control logic tuning to verify that setpoints match

the intended design

Feed Water Application (SWIL) Feed Water Application (SWIL)

● Validation of plant dynamic performance using transient test

scenariE l os;

Examples:

– Ramp Load Increase from 1% Power to Turbine Synchronization Power Level at 1%/min

– Turbine Synchronization and Initial Load Pickup

– T bi T i With t R t T i ( t i t l l) Turbine

Trip Without Reactor

Trip (at appropriate power level)

– 100% Power ±10% Load Swing

– 100% Power Ramp Load Decrease to 15% Power at 5%/min (bringing on various pumps at the

appropriate power)

– 1 % 100% %/ ( ff 15

% Power Ramp Load Increase to 100% Power at 5%/min (taking off various pumps at the

appropriate power level)

– Large Load Rejection (dependent upon plant design typically either 50 or 100% capability)

– Loss of One Feedwater Pump

– Level Setpoint Step at 5% Power

– Level Setpoint Step at 100% Power

– Level Setpoint Step at 50% Power with One Feedwater Pump Operating

– Level Set

point Ste

p at 50% Power with Two Feedwater Pum

ps O

peratin

g.

Feed Water Application Software (SWIL) Feed Water Application Software (SWIL)

● Key Customer representatives participate in testing:

– Operations, systems engineering, training, etc.

● Results of the testing (trend plots, Control Builder mark-ups,

and logbook entries) are collected into a test report and

archived.

● Upon successful completion of this testing, the application

software is ready for loading into simulator and FAT on

target plant hardware.

Westinghouse Test Plan Overview Westinghouse Test Plan Overview

● Covers validation test approach.

● Each test phase builds upon previous testing in an Each test phase builds upon previous testing in an

overlapping, structured approach in the order listed below:

1. Initial Software Debug Tests

2. Testing of Application Software (includes dynamic SWIL tests)

3. Simulator Testing

4. FAT 1: Target Hardware (power up, controller/network FAT 1: Target Hardware (power up, controller/network

redundancy failover & I/O checkout)

5. FAT 2: Base System Hardware/software (network, OWS, EWS,

AVS Domain workstation and system security configurations AVS, Domain workstation and system security configurations

6. FAT 3: Including signal validation, graphics, hardware alarms

output redundancy and application hardware )

7 Site Testing site acceptance tests and po er ascension test

25

. Site Testing

– site acceptance tests and po

wer ascension test

Feed Water (FW) Control Systems Feed Water (FW) Control Systems

In delivering digital FW control systems,

W ti h li Westing

house applies:

• High Quality Application Software Development

Process

– Software Requirements Document

– Software Description Document

– S ft Lif l Pl S

oftware Lifecycle Plan

– Failure Modes and Affects Analysis (software and hardware)

– Software Hazards Analysis

– P i t t ith 10CFR50 A di B Processes consis

ten

t with 10CFR50

Appendix

B

where commercial grade application software can be

applied in critical applications

Feed Water (FW) Control Systems Feed Water (FW) Control Systems

Westinghouse NA uses “defense in design” to

ens re deli er of a high q alit prod ct ens

ure deli

very of

a high

q

uality prod

uct:

• Plant Specific Models and validation testing with application in closed

loop demonstrates deterministic behavior of the application early in

d i es gn process

• Applications are partitioned on controllers such as not to cause failures

that could add positive reactivity or effect plant design basis

• Reliance on the control network is limited Reliance on the control network is limited

– controllers and associated controllers and associated

I/O can continue to function with loss of network

• I/O designed on controller loss to revert to known or benign state

• For critical control component, a hard control station is provided to For critical control component,

a hard control station is provided to

operator manual control – another layer of redundancy

• Redundancy of system components at all levels

Existing Analog Feed Water Control Existing Analog Feed Water Control

● Historically, Steam Generator Water Level has

been difficult to contro

l

– Analog-based systems are limited

– Per INPO data; second leading system for plant trip

– Steam Generator (SG) shrink and swell phenomena

– Steam & Steam

& feedwater feedwater measurement unreliable at low power levels measurement unreliable at low power levels

– Manual control with multiple operators required to bring up unit

– Prone to single points of failure

Analog Inputs – no active redundancy

Manual operator action in detecting input failures

Modulating Outputs single driver card

29

Modulating Outputs

– single driver card

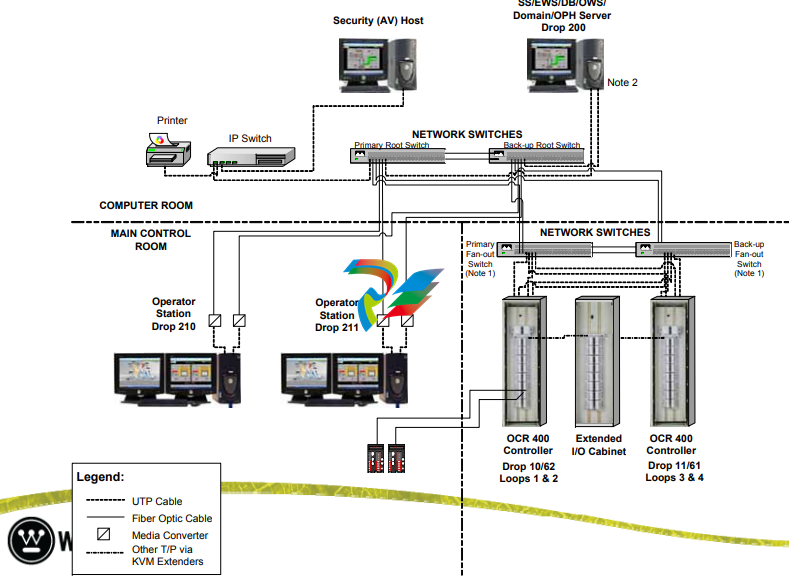

Typical Advanced Digital Feed Water

System (ADFCS) Configuration System (ADFCS) Configuration

● 1,2, 3 or 4 Redundant Controllers:

● HMI -T O t W k t ti ith ft t l Two

Opera

tor

Wor

k

s

t

ations with soft con

trols

– M/A Stations for FW Valve & FP Controls

● One Engineer One Engineer s/Data ’s/Data Base Server Workstation Base Server Workstation

● Network Equipment – Fast Ethernet Switches

● Anti-virus Station

● New Cabinets or retrofit of existing cabinets

● SLIM M/A’s for Main, Bypass and Feed Pumps

ADFCS

– Main Control Room Main Control Room

● Redundant operator stations & LCD

displays in MCR displays in MCR 59 0 PCT

● SLIM M/A’s for all modulating valves, &

feed pumps

Add d l f d d

59.0 PCT

100

SP PV OUT

100

Add

e

d layer o

f re

dun

dancy upon

controller failure

Works seamlessly with soft control

80

60 60

80

● Remove signal selector switches

● Remove select recorders – steam/feed

water, wide and narrow ran

ge level 20

40

20

40

, g

● Remove individual channel indicators &

replace with median

● Select indicators can remain

“live

”

Typical ADFCS Architecture Typical ADFCS Architecture

ADFCS

– Design Overview Design Overview

● Improved system reliability via signal selectors

– Narrow Range Level

– Wide Range Level

– Feedwater Flow

– Steam Flow

– Steam Pressure

– Feedwater Tem

perature

– Turbine Impulse Pressure or Nuclear Power

– Feedwater Header Pressure

( ) FP turbine runback)

● Improve System performance by integrating feed pump governor controls

ADFCS

– Design Overview Design Overview

● Proven Control Application – third generation

design consistent with AP1000 design consistent with AP1000

– Low and High Power Controllers

Bumpless Transfer between Low Power and High

P C t lM d Power

Con

tro

l

M

o

de

– Feedwater Temperature Compensation

Low Power Level Controller gain & reset adjusted Low Power Level Controller gain

& reset adjusted

based on feedwater temperature

Compensates for the effects of shrink and swell in

ll t eve

l response

to fd t ee

dwa

ter fl i ti flow variations

– High Power Level Controller proportional gain and

integral time adjusted based on steam flow

35

integral time adjusted based on steam flow

ADFCS

– Design Overview Design Overview

● Proven Control Application (cont’d)

– Load Index Load Index

Wide Range Level

Anticipates need for flow change at low power

– Automatic transition from bypass valve to main feed Automatic transition from bypass valve to main feed water regulation valve

– Capability of operating with one valve in manual and other in auto other in auto

– Control Valve Linearization & Performance

Compensates for non-linearities in valve characteristics and ensures an effective and stable

control response

Position feedback provides means to detect sticking or sluggish valve response and alert the operator

ADFCS

– Design Overview Design Overview

● Proven Control Application (cont’d)

– F d d d d i l l t d f ti f Fee

d pump spee

d

deman

d is calcula

t

e

d as a

function o

f

feed water flow demand

Provide adequate pump head to ensure flow to the

steam generators is maintained during transients

Coordinated automatic control of steam driven feed

pp g um

ps when inte

grated into ADFCS

ADFCS

– Design Overview Design Overview

● Proven Control Application (cont’d)

– S it h t M l d i t l ith S

wit

c

h

to

Manual mo

de in new sys

tem only occurs with

complete Narrow Range Level failure; otherwise system

remains in Automatic for all other failures

Steam or feedwater flow input failure; system reverts Steam or feedwater flow input failure; system reverts

to single element control with a reduced steam

generator narrow range level error input to the flow

controller PID. controller PID.

Steam pressure, feedwater temperature and

feedwater header pressure input failures; system

uses a constant value of the signal that is

representative of the signal prior to the failure

Advanced Digital Feed Water Advanced Digital Feed Water

● Benefits

– Proven 3rd Generation Design used on Westinghouse and CE plants, deployed

in eleven units with two additional in next two years; common design with

AP1000

– Standardized proven and enhanced control logic used for highly reliable Standardized, proven and enhanced control logic used for highly reliable

operational performance allowing operational maneuvers with no level deviation

– Auto control over full power range (1-100%), heatup/cooldown (optional)

– Auto, seamless transition between main/bypass feed water regulation valves

– Bumpless transition from Automatic mode to Manual mode and back

– Allows Integrated governor control and protection of main feed water pump

speed

– Plant

-specific dynamic analysis per SWIL addresses plant components & specific dynamic analysis per SWIL addresses plant components

&

operational conditions

– Supports transient capability with reduced risk of reactor trip

– Minimized field tunin

g and risk of dela

ys at startup

Advanced Digital Feed Water Advanced Digital Feed Water

Benefits (cont)

– Integrated governor control and protection of Integrated governor control and protection of

main feed water pump speed governor

– Operational maneuvers with no narrow range

level deviation

– Output redundancy to control valves

available that provides additional layer of

protection against SPV and loss of

red d t t ll dun

dant controllers

– SLIM hard interface operates seamlessly

with Soft Control Interface graphics

– A tomatics s itch to man al and alternate A

utomatics

s

witch to man

ual and alternate

actions

– SONG’s and Almaraz have tripped a feed

pump at power and stayed on line

Almaraz Feed Pump

Turbine

41

pump at power and stayed on line