ABBDistributed busbar protection REB500 including line and transformer protection Product Guide

REB500 system in a simple way.

Fig. 5 Bay unit

Central unit (500CU03)

The hardware structure is based on standard

racks and only a few different module types

for the central unit (see Fig. 4).

The modules actually installed in a particular

protection scheme depend on the size, complexity and functionality of the busbar system.

A parallel bus on a front-plate motherboard

establishes the interconnections between the

modules in a rack. The modules are inserted

from the rear.

The central unit is the system manager, i.e. it

configures the system, contains the busbar

replica, assigns bays within the system, manages the sets of operating parameters, acts as

process bus controller, assures synchronization of the system and controls communication with the station control system.

The variables for the busbar protection function are derived dynamically from the process

data provided by the bay units.

The process data are transferred to the central processor via a star coupler module. Up to

10 bay units can be connected to the first central processor and 10 to the others. Central

processors and star coupler modules are

added for protection systems that include

more than 10 bay units. In the case of more

than 30 bay units, additional casings are

required for accommodating the additional

central processors and star coupler modules

required.

All modules of the central unit have a plugand-play functionality in order to minimize

module configuration.

One or two binary I/O modules can be connected to a central processing unit.

The central unit comprises a local HMI with 20

programmable LEDs (Fig. 6), a TCP/IP port

for very fast HMI500 connection within the

local area network.

Distributed busbar protection REB500

including line and transformer protection

Page 9

Functionality Busbar protection

The protection algorithms are based on two

well-proven measuring principles which have

been applied successfully in earlier ABB lowimpedance busbar protection systems:

• a stabilized differential current measurement

• the determination of the phase relationship

between the feeder currents (phase comparison)

The algorithms process complex current vectors which are obtained by Fourier analysis

and only contain the fundamental frequency

component. Any DC component and harmonics are suppressed.

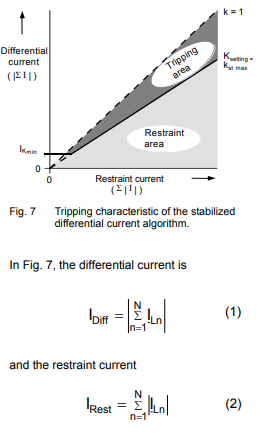

The first measuring principle uses a stabilized

differential current algorithm.

The currents are evaluated individually for

each of the phases and each section of busbar (protection zone).

where N is the number of feeders. The following two conditions have to be accomplished

for the detection of an internal fault:

where

kst stabilizing factor

kst max stabilization factor limit.

A typical value is kst max = 0.80

IK min differential current pick-up value

The above calculations and evaluations are

performed by the central unit.

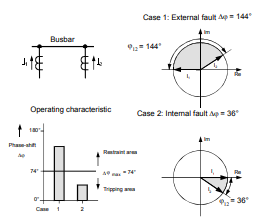

The second measuring principle determines

the direction of energy flow and involves comparing the phases of the currents of all the

feeders connected to a busbar section.

The fundamental frequency current phasors

1..n (5) are compared. In the case of an internal fault, all of the feeder currents have almost the same phase angle, while in normal

operation or during an external fault at least

one current is approximately 180° out of

phase with the others

The algorithm detects an internal fault when

the difference between the phase angles of all

the feeder currents lies within the tripping

angle of the phase comparator (see Fig. 8).

Distributed busbar protection REB500

including line and transformer protection

The task of processing the algorithms is

shared between the bay units and the central

processing unit. Each of the bay units continuously monitors the currents of its own fee-der,

preprocesses them accordingly and then filters the resulting data according to a Fourier

function. The analog data filtered in this way

are then transferred at regular intervals to the

central processing unit running the busbar

protection algorithms.

Depending on the phase-angle of the fault,

the tripping time varies at Idiff/Ikmin5 between 20 and 30 ms including the auxiliary

tripping relay.

Optionally, the tripping signal can be interlocked by a current or voltage release criteria

in the bay unit that enables tripping only when

a current above a certain minimum is flowing,

respectively the voltage is below a certain

value.

Breaker failure protection

The breaker failure functions in the bay units

monitor both phase currents and neutral current independently of the busbar protection.

They have two timers with individual settings.

Operation of the breaker failure function is

enabled either:

• internally by the busbar protection algorithm (and, if configured, also by the internal line protection, overcurrent or pole

discrepancy protection features) of the bay

level

• externally via a binary input, e.g. by the line