ABBDistributed busbar protection REB500 including line and transformer protection Product Guide

next disturbance (FIFO = First In, First Out).

This function is performed in a stand-alone

mode in the bay unit (see page 7).

Note:

Stored disturbance data can be transferred via

the central unit to other computer systems for

evaluation by programs such as PSM505 [3].

Files are transferred in the COMTRADE format.

After retrieving the disturbance recorder data,

it is possible to display them graphically with

PSM505 directly.

Communication interface

Where the busbar protection has to communicate with a station automation system (SAS),

a communication module is added to the central unit. The module supports the interbay

bus protocols IEC 61850-8-1, IEC 60870-5-

103 and LON.

The IEC 61850-8-1 interbay bus transfers via

either optical or electrical connection:

• differential current of each protection zone

• monitoring information from REB500 central unit and bay units

• binary events (signals, trips and diagnostic)

• trip reset command

Distributed busbar protection REB500

including line and transformer protection

• disturbance recording data (via MMS file

transfer protocol)

• time synchronization with Simple Network

Time Protocol (SNTP)

• two independent time servers are supported. Server 2 as backup time

The LON interbay bus transfers via optical

connection:

• differential currents of each protection zone

• binary events (signals, trips and diagnostic)

• trip reset command

• disturbance recording data (via HMI500)

• time synchronization

The IEC 60870-5-103 interbay bus transfers

via either optical or electrical connection:

• time synchronization

• selected events listed in the public part

• all binary events assigned to a private part

• all binary events in the generic part

• trip reset command

Test generator

The HMI program (HMI500) which runs on a

PC connected to either a bay unit or the central processing unit includes a test generator.

During commissioning and system maintenance, the test generator function enables the

user to:

• activate binary input and output signals

• monitor system response.

• test the trip circuit up to and including the

circuit-breaker

• test the reclosure cycles

• establish and perform test sequences with

virtual currents and voltages for the bay

protection of the REB500sys

The test sequencer enables easy testing of

the bay protection without the need to decommission the busbar protection. Up to seven

se-quences per test stage can be started. The

sequences can be saved and reactivated for

future tests.

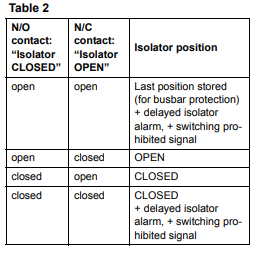

Isolator supervision

The isolator replica is a software feature without any mechanical switching elements. The

software replica logic determines dynamically

the boundaries of the protected busbar zones

(protection zones). The system monitors any

inconsistencies of the binary input circuits

connected to the isolator auxiliary contacts

and generates an alarm after a set time delay.

In the event of an isolator alarm, it is possible

to select the behavior of the busbar protection:

• blocked

• zone-selective blocked

• remain in operation

Differential current supervision

The differential current is permanently supervised. Any differential current triggers a timedelayed alarm. In the event of a differential

current alarm, it is possible to select the

behavior of the busbar protection:

• blocked

• zone-selective blocked

• remain in operation

Trip redirection

A binary input channel can be provided to

which the external signal monitoring the circuit-breaker air pressure is connected. Tripping is not possible without active signal.

When it is inactive, a trip generated by the

respective bay unit is automatically redirected

to the station at the opposite end of the line

and also to the intertripping logic to trip all the

circuit-breakers connected to the same section of busbar.

The trip redirection can also be configured

with a current criterion (current release criteria).

Distributed busbar protection REB500

including line and transformer protection

Page 13

Human machine interface (HMI)

The busbar protection is configured and maintained with the aid of human machine interfaces at three levels.

Local HMI

The local display interface installed in the central unit and in the bay units comprises:

• a four-line LCD with 16 characters each for

displaying system data and error messages

• keys for entering and display as well as 3

LEDs for the display of trips, alarms and

normal operation.

• in addition 20 freely programmable LEDs

for user-specific displays on the bay unit

500BU03 and central unit 500CU03.

The following information can be displayed:

• measured input currents and voltages

• measured differential currents (for the busbar protection)

• system status, alarms

• switchgear and isolator positions (within

the busbar protection function)

• starting and tripping signals of protection

functions

External HMI (HMI500)

More comprehensive and convenient control

is provided by the external HMI software running on a PC connected to an optical interface