HarmonicHarmonic Drive™ servo

Read this manual thoroughly before designing the application, installation, maintenance or inspection of the actuator.

Indicates a potentially hazardous situation,

which, if not avoided, could result in death

or serious personal injury.

Indicates a potentially hazardous situation, which, if

not avoided, may result in minor or moderate personal

injury and/or damage to the equipment.

LIMITATION OF APPLICATIONS:

The equipment listed in this document may not be used for the applications listed below:

¨ Space equipment ¨ Automobile, automotive parts

¨ Aircraft, aeronautic equipment ¨ Amusement equipment, sport equipment, game machines

¨ Nuclear equipment ¨ Machine or devices acting directly on the human body

¨ Household apparatus ¨ Instruments or devices to transport or carry people

¨ Vacuum equipment ¨ Apparatus or devices used in special environments

If the above list includes your intending application for our products, please consult us.

Safety measures are essential to prevent accidents resulting in death, injury or damage of the equipment due to

malfunction or faulty operation.

CAUTIONS FOR ACTUATORS AT APPLICATION DESIGNING

Always use under followings conditions:

-Ambient temperature: 0℃ to 40℃

-Ambient humidity: 20% to 80%RH (Non-condensation)

-Vibration: Max 24.5 m/S2

-No contamination by water, oil

-No corrosive or explosive gas

Follow exactly the instructions in the relating

manuals to install the actuator in the equipment.

-Ensure exact alignment of motor shaft center and

corresponding center in the application.

Failure to observe this caution may lead to vibration,

resulting in damage of output elements.

CAUTION FOR ACTUATORS IN OPERATIONS

Keep limited torques of the actuator.

-Keep limited torques of the actuator.

-Be aware, that if arms attached to output element hits

by accident an solid, the output element may be

uncontrollable.

Never connect cables directly to a power supply

socket.

-Each actuator must be operated with a proper driver.

-Failure to observe this caution may lead to injury, fire or

damage of the actuator.

Do not apply impacts and shocks

-Do not use a hammer during installation

-Failure to observe this caution could damage the

encoder and may cause uncontrollable operation.

Avoid handling of actuators by cables.

-Failure to observe this caution may damage the wiring,

causing uncontrollable or faulty operation.

CAUTIONS FOR DRIVERS AT APPLICATION DESIGNING

Always use drivers under followings conditions:

-Mount in a vertical position keeping sufficient distance

to other devices to let heat generated by the driver

radiate freely.

-Ambient temperature: 0℃ to 50℃

-Ambient humidity: less than 95% RH (Non

condensation)

-No contamination by water, oil or foreign matters

-No corrosive, inflammable or explosive gas

Use sufficient noise suppressing means and safe

grounding.

-Keep signal and power leads separated.

-Keep leads as short as possible.

-Ground actuator and driver at one single point, minimum

ground resistance class: D (less than 100 ohms)

-Do not use a power line filter in the motor circuit.

Pay attention to negative torque by inverse load.

–Inverse load may cause damages of drivers.

-Please consult our sales office, if you intent to apply

products for inverse load.

Use a fast-response type ground-fault detector

designed for PWM inverters.

-Do not use a time-delay -type ground-fault detector.

CAUTION FOR DRIVERS IN OPERATIONS

Never change wiring while power is active.

-Make sure of power non-active before servicing the

products.

-Failure to observe this caution may result in electric

shock or personal injury.

Do not touch terminals or inspect products at least

5 minutes after turning OFF power.

-Otherwise residual electric charges may resul t in

electric shock.

-Make installation of products not easy to touch their

inner electric components.

Do not make a voltage resistance test.

-Failure to observe this caution may result in damage of

the control unit.

-Please consult our sales office, if you intent to make a

voltage resistance test.

Do not operate control units by means of power

ON/OFF switching.

-Start/stop operation should be performed via input

signals.

Failure to observe this caution may result in deterioration

of electronic parts.

DISPOSAL OF AN ACTUATOR, A MOTOR, A CONTROL UNIT AND/OR THEIR PARTS

All products or parts have to be disposed of as industrial waste.

-Since the case or the box of drivers have a material indication, classify parts and dispose them separately.

Functions

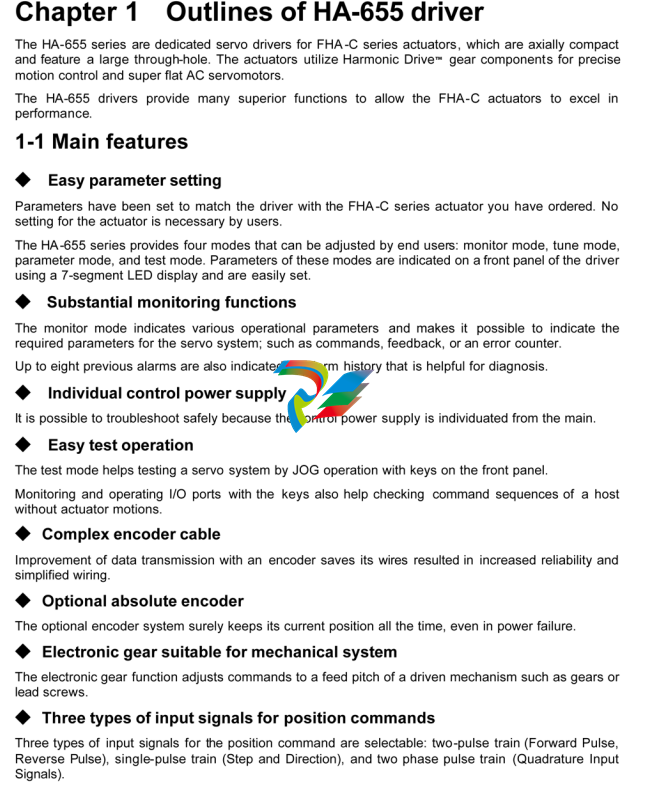

◆ LED display

Indicates operating states of the HA-655 driver, parameters, alarms, by a 6-digit 7segment-LED.

◆ Keys labeled [UP], [DOWN], [ADJ], and [SET]

Are used for changing indications, setting and tuning functional parameters, and operating an actuator

manually in a JOG mode.

◆ CN1: encoder connector

Accepts a connector of an encoder cable form an actuator.

◆ CN2: I/O connector

Accepts I/O signals to/from a host device.

◆ CN3: Serial port connector (compliant with RS-232C)

Is connected to a PC with a dedicated cable. You can monitor, set, and tune parameters on the PC’s

display. (Notice: Optional software is available.)

◆ Power supply terminals: r, s, R, S, T

Are provided for connecting the power supply. Control power is supplied to the [r, s] terminals, and main

power is supplied to the [R,S,T] terminals. (single Phase: R,S; or three phase: R,S,T).

◆ External regeneration resistor terminals: R1, R2

If the built-in regeneration resistor is insufficient in its capacity to handle frequent start/stop operations of

an actuator, an external resistor can be connected to these terminals.

◆ Actuator terminals: U, V, W

Accept an actuator cable. Connect each motor wire to the driver’s terminal marked with a same symbol.

If you confuse the symbols, the driver and the actuator may be in failure.

◆ Ground terminals (Protective earth)

Connect grounds here to prevent electrical shock.

1-7 Outlines of I/O ports

The CN2 connector provides input and output signals to and from a host device. The 50 pins of the

connector are assigned to the following signals in each of the [position mode] and the [speed mode].

(Notice: Do not connect signals to pins marked “-“.)

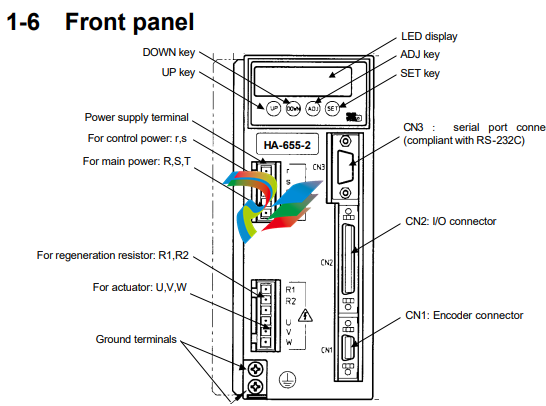

1-8 Operating display panel

The HA-655 driver provides a 6-digit LED display and four operation keys on the front panel. The panel

executes monitoring, tuning, setting, and JOG operation.

1-8-1 Outlines of operation modes

The HA-655 driver provides the following four modes: monitoring, tuning, setting, and operations.

◆ Monitor mode

The HA-655 driver displays position and speed commands, a current position from a motor-encoder, a

pulse count in an error counter, states of input and output signals, load conditions, alarm histories, and a

code number for the actuator for which the driver is set. The mode can be used for diagnosing an

abnormal driver.

After power supply, the monitor mode starts up and works as the hub of other three modes for operation.

◆ Tune mode

The tuning mode includes various parameters to control the actuator motion. Setting the most suitable

value for each parameter obtains the optimum performance of the actuator.

◆ Parameter mode

The parameter mode sets various parameter values relating to the fundamental operational functions

such as: specifications of the position mode or the speed mode, configurations of input signals, an

electronic gear function, limiting values of speed and torque, and parameters to communicate with a

host.

◆ Test mode

The test mode includes required functions for system tests; such as JOG operation functions, operations

of pseudo output signals, I/O signal monitors, and so on.

1-8-2 Selecting a mode

After powering the driver, the monitor mode starts up automatically. The [ADJ] and [SET] keys select a

mode.

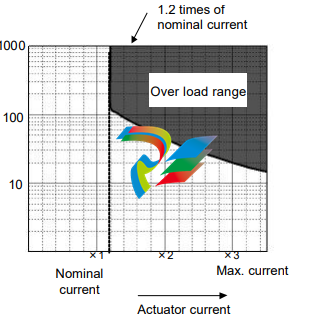

1-9-2 Protective functions

The HA-655 driver provides the following alarms to protect the servo system, and presents an alarm

code on the preceding paragraph.

◆ Over speed (10)

If a motor exceeds its maximum speed or if motor rotates abnormally, the alarm occurs. To clear the

alarm, shut off the control power once and turn it on again.

◆ Over load (20)

The driver always monitors the motor current, and if the current exceeds the curve in the figure below,

the overload alarm occurs.

For example:

(1) The alarm occurs if the current

slightly exceeds 1.2 times of

nominal current for a long

duration.

(2) The alarm occurs if the current of

three times of the nominal current

flows for 20 seconds.

It is possible to clear the alarm by

inputting signal to [CN2-2 clear:

CLEAR].

◆ Overheat (21)

The alarm occurs by activating the thermal switch of an IPM element in the HA-655 driver. To clear the

alarm after troubleshooting, shut off the control power once and turn it on again.

◆ Over current (30)

The alarm occurs when the servo control element of the driver detects excessive current. To clear the

alarm after troubleshooting, shut off the control power once and turn it on again.

◆ Abnormal regeneration (41)

The alarm occurs by activating the thermal switch of the regeneration resistor in the HA-655 driver at

100℃. To clear the alarm after troubleshooting, shut off the control power once and turn it on again.

◆ Encoder failure (50)

The alarm occurs when the encoder signal ceases. To clear the alarm after troubleshooting, shut off the

control power once and turn it on again.

The alarm also occurs when a built-in battery of the HA-655 driver for the absolute encoder is taken off in

spite of normal conditions. To clear the alarm, shut off the control power once and turn it on again.

◆ Abnormal encoder signal (51)

The alarm occurs when the driver has failed to receive two sequential signals. To clear the alarm after

troubleshooting, shut off the control power once and turn it on again.

◆ UVW failure (52)

The alarm occurs when the encoder UVW signals are abnormal. To clear the alarm after troubleshooting,

shut off the control power once and turn it on again.

◆ ABS system failure (53)

For the absolute encoder, the alarm occurs when all power supplies (power supply, built-in condenser,

and battery) for the encoder are failure. For example, it occurs at the first power supply after purchasing,

and at power supply after disconnecting the cable between the driver and the encoder for a long duration.

To recover the alarm, input the multi-turn data clear signal at least 4 seconds, and shut off the control

power once and turn it on again.

◆ ABS MTD overflow (54)

For the absolute encoder, the alarm occurs when the count for multi-turn data (MTD) goes beyond the

range of +4095 to - 4096 turns (motor axis). To recover the alarm, input the multi-turn data clear signal at

least 4 seconds, and shut off the control power once and turn it on again.

◆ ABS multi-turn data error (55)

For the absolute encoder, during an energy-saving mode, where no power by power supply but the

encoder circuit is active only by the power of a built-in condenser and a built-in battery, the alarm occurs

when the encoder rotates too fast at the acceleration rate and speed exceeding the recording ability of

the multi-turn counter on the mode. To recover the alarm, input the multi-turn data clear signal at least 4

seconds, and shut off the control power once and turn it on again.

◆ ABS low battery voltage (56)

For the absolute encoder, when voltage of the built-in battery is low. To recover the alarm, change the

battery for a new one, and shut off the control power once and turn it on again.

◆ ABS send data rule error (57)

The absolute encoder rotates more than 127 resolvable pulses by external torque during transmitting

absolute data. To recover the alarm, shut off the control power once and turn it on again.

◆ Error counter overflow (60)

The alarm occurs when an error count exceeds the set value in [parameter mode]→[6: position error

allowance]. It is possible to clear the alarm by inputting a signal to [CN2-2 clear: CLEAR]. The error

count is cleared at the same time.

◆ Memory failure (RAM) (70)

The alarm occurs when the driver’s RAM memory fails. It is impossible to clear the alarm.

◆ Memory failure (EEPROM) (71)

The alarm occurs when the driver’s EEROM memory fails. It is impossible to clear the alarm.

◆ CPU failure (76)

The alarm occurs when the driver’s CPU fails. It is impossible to clear the alarm.

Chapter 2 Functions

2-1 Control system of the HA-655 driver

It is said that [plan, do, see] is essential to perform perfect

jobs. In other words, the [plan, do, see] is the repeating

cycle of command→action→result→feedback→modified

command → action → feedback →・・・・ .

Driving machines precisely requires the same control as

the above job cycle, that is [Motion command→run→

feedback→modified command→・・・・].

For example, assume the required motion is rotation to a

target angle and stopping there. To perform the motion,

the motor must be equipped with an angular sensor to

detect a current position, and the position data must be

compared with the command. If the position data is

different than the command, the motor rotates until the

position data becomes equal to the command. This is an

example of a position servo system.

The speed control system is the same. The motor is

equipped with a speed sensor and the speed is compared

with the speed command. If the speed is different from the

command, the motor accelerates or decelerates until the

motor speed becomes equal to the command. This is an

example of the speed servo system.

The HA-655 driver realizes above both controls of position and speed with the same unit.

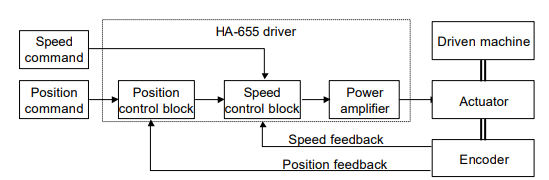

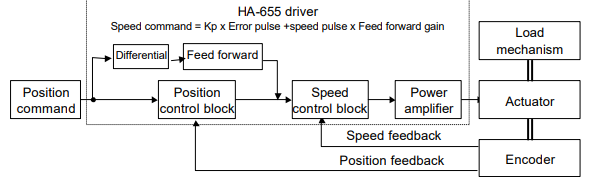

The fundamental configuration of servo system of the HA-655 driver is as follows:

The HA-655 driver function is consists of three parts: the position control block, the speed control block,

and the power amplifier.

In the position mode, a command position from a host is compared to a feedback position. If there is a

difference between them, the position control block commands the power amplifier through the speed

control block to flow current to the actuator until there is no difference.

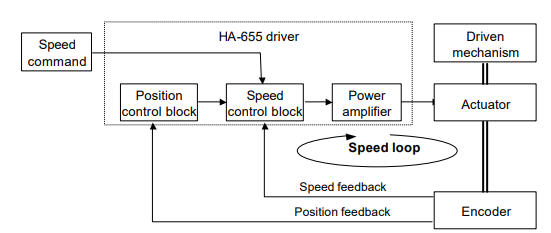

In the speed mode, a speed command is directly inputted to the speed control block. The speed block

compares the command and current feedback speed. If there is a difference between them, the speed

control block commands to the power amplifier flow the current to the actuator until there is no

difference.

The HA-655 driver allows two types of encoder as a functional member of the feedback system,

optionally: an incremental encoder or an absolute encoder.

2-2 Position mode

The HA-655 driver makes use of either the position control or the speed control. This section describes

the position mode. (※ The default setting is the [position mode].)

Before driving, set the control mode by [parameter mode] → [0: control mode].

2-2-1 Command configuration in position mode

In the position mode, the command is transmitted from a host in the form of a digital pulse signal train.

The HA-655 driver provides two pair of two ports (CN2-27&28, CN2-29&30) for the command pulses.

Signals of three type of configurations are available for the ports.

● Setting a command configuration

[Parameter mode]→[1: command configuration]

● Relating I/O pins

Input pins: CN2-26 to 30

(1) 2-pulse train (FWD and REV pulse train)

Two pairs of two terminals are provided, and each of FWD and REV pulse trains is assigned a pair

independently. FWD commands and REV commands are inputted in the pair of FWD ports and REV

ports respectively, as shown in the figure below. When signals are inputted to a pair of terminals, the

signal to the other should keep [OFF] state.

(2) 1-pulse train (polarity + pulse train)

One pair of terminals is assigned dedicatedly for command pulse train, and the other is assigned to a

sign for rotary direction. Position commands are inputted in the FWD port pair only and the REV port pair

accepts the sign of rotary direction, as shown in the figure below. [OFF] or [Low level] state is for the

FWD command and [ON] or [High] level is for the REV command.

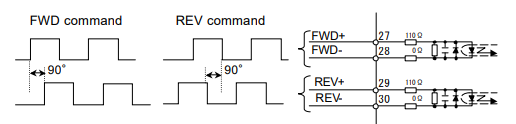

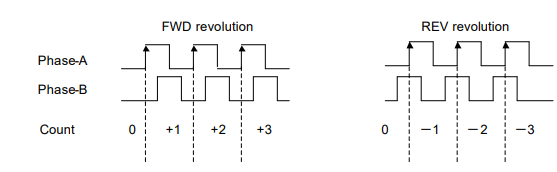

2-phase pulse train (A-B phase pulses with 90 degree difference)

Both port pairs receive the command pulse trains that have a 90 electric degree difference relative to

each other as shown in the figure below. For the FWD command, the pulse train to the FWD ports

advances 90 degrees from the REV port train. For the REV command, the REV port train advances from

the FWD port train.

The encoder pulse trains to the driver have this 2-phase pulse configuration

◆ Multiplication of command

When the command configuration is a

[2-phase pulse] type, it is possible to multiply

the command pulse train by 2 or 4 for the

command pulse train to an actuator.

The encoder feedback pulse train is

quadrupled.

● Setting

[Parameter mode] → [2: multiplication of

2-phase pulse]

◆ Electronic gear

The electronic gear function can be set make a given

displacement of the driven mechanism for one

command pulse, an integer, or a convenient number.

For example, it is convenient to set the displacement of

0.1 micrometer for one pulse as shown in figure to the

right.

The function multiples the command pulse count by the

coefficient (fraction).

The relation of [denominator / numerator] of the coefficient

is obtained as follows:

2-2-2 Command transmitting system

Two systems are provided for transmitting command pulses: [open collector] and [line driver].

◆ Open collector system

This system employs a transistor whose emitter is

common and whose collector is open. Since the

output signal is voltage type, this system is

unsuitable for long distance transmission due to line

voltage drop.

◆ Line driver system

The line driver system conforms to (EIA) RS-422

standard providing line drivers for transmitting

signal pulses. Since the output signal is current type,

this system is suitable for long distance

transmissions without attenuation of signals.

Furthermore, the line driver system transmits data

faster than the open collector system.

2-2-3 Outputting encoder signals

Two kinds of encoder are selectable for the FHA-C

series actuator: incremental or absolute. The

incremental encoder feeds back two pulse-trains

into the HA-655 driver as shown in the figure to the

right. The pulse trains are called [phase-A] and

[phase-B]. For the encoder resolution, refer to

actuator’s technical manual.

On the other hand, the absolute encoder feeds back

a combination of absolute signals and two

pulse-train signals.

In addition to the 2-phase pulse trains, both

encoders output a [phase-Z] pulse signal once per

motor rotation for use as an origin. The pulse signal

is sometimes called [phase-C] or [index].

The HA-655 driver outputs encoder signals using a

line driver system. The signals can be received by a

line receiver: AM26LS32 (EIA-422A) or equivalent.

Phase-Z signal is also available (open collector

output {CN-42 pin}).

The phase-Z signal is asynchronous.

Three encoder signals mentioned above are

available for a host.

● Relating I/O pins

Output pins: CN2-42 to 49

2-2-4 Absolute encoder signals

u General descriptions and functions of absolute encoders

The absolute encoder housed in a FHA-C series actuator provides an absolute sensor to generate an

absolute pulse train for a resolvable position (the sensor is herein after referred to as “single-turn

encoder”.), and an electronic counter to generate an absolute pulse train for a revolution of the motor

(the counter is hereinafter referred to as “multi-turn counter”.).

An absolute position of the encoder is kept in the memory, which is always energized by a combination

of the built-in condenser in the actuator and the backup battery housed in the HA-655 driver.

Please interpret that “single-turn” and “multi-turn” in the manual mean one and plural revolutions of the

encoder (the motor) in an actuator, respectively. Therefore, the actual actuator resolvable position of

either “single-turn” or “multi-turn” can be obtained by multiplying an absolute pulse train of the single-turn

encoder and the multi-turn counter by a reduction ratio of the actuator.

u Single-turn absolute encoder

The single-turn encoder is composed of an encoder disk, an LED light source, and a photo-detector. The

single-turn absolute encoder system outputs a current absolute pulse train combined with an absolute

pulse train of the multi-turn counter in response to the [ABS data request] signal. The resolution of the

encoder is 8192 positions per turn (13 bits). To obtain actual resolvable position of the actuator, the

absolute pulse train should be multiplied by the reduction ratio of the actuator.

u Multi-turn counter

The multi-turn counter outputs a current absolute pulse train combined with an absolute pulse train of

the single-turn absolute encoder system in response to the [ABS data request] signal. The allowed

range of the counter is from +4095 to –4096. To obtain an actual resolvable position of the actuator, the

absolute pulse train should be multiplied by the reduction ratio of the actuator.

u Energy-saving mode

In the energy-saving mode, even during no power supply for the HA-655 driver, the multi-turn counter

keeps a count in its memory only by the power of a built-in condenser and a built-in battery.

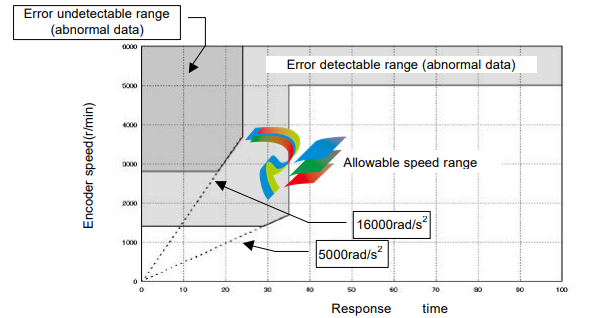

u Allowable encoder (motor) speed in energy-saving mode

The limit of an encoder (a motor) speed is 5,000r/min. The [alarm 55: ABS multi-turn data error] occurs if

the encoder rotates at more than the limited speed, and a correct absolute pulse train of the multi-turn

counter may not obtained. Moreover, there are additional limits during motor acceleration duration as

shown the figure below

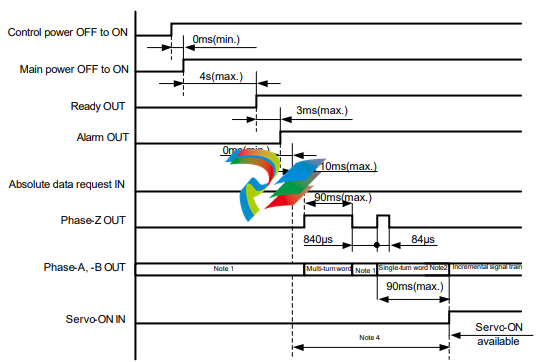

u Notice at power on If power is turned on while the motor rotates at 2800r/min or more, the [Alarm 55] may occur. In spite of the alarm, the multi-turn counter works normal. u ABS (multi-turn) data clear signal (CN2-11: ABS-CLEAR) The ABS (multi-turn) data clear signal should be inputted at: (a) the initial power supply, and; (b) wasting about 30 minutes or more for exchanging the built-in battery. At either case, the multi-turn counter does not keep any data. To recover from the problem, move the actuator to a proper origin and input the [ABS (multi-turn) data clear signal] at least four seconds to clear the multi-turn counter to zero. However, the single-turn encoder keeps its resolvable position during above-mentioned operation firmly. During exchanging the battery, the built-in condenser helps the multi-turn counter to keep its count at least about 30 minutes with charged energy in the condenser. Therefore, the operation of inputting [ABS (multi-turn) data clear signal] is not required before discharging the energy. Though the [alarm 50: encoder failure] may occur at power ON operation after exchanging the battery, the encoder system is normal. To recover the problem, shut off the power once and turn it on again. u Acquisition of absolute pulse trains generated by absolute encoder system The HA-655 driver provides two selectable acquisition methods of absolute pulse trains generated by the absolute encoder system; from I/O ports and from CN3 port (RS-232C). (a) Acquisition from I/O ports (CN2-44, -45 and CN2-46, -47) Acquiring an absolute pulse train An absolute pulse train of an absolute encoder system is a combination of an absolute code (13 bits) of the multi-turn counter expressing an encoder’s revolution number from its origin, and an absolute code (13 bits) of the single-turn encoder expressing a resolvable position of the encoder (the motor). Incremental signal trains following to the absolute pulse train of an absolute encoder system may be used for monitoring signals of operating condition of the motor. As a rule, acquiring an absolute pulse train is possible only one time during power ON procedure illustrated below. If acquiring an absolute pulse train is required at another timing, use the CN3 port for acquiring while the motor is stopping.

Note 1: Both output signals of phase-A and phase-B are settled at LOW-level. To settle at LOW-level, at

least three pulses are outputted. Make a sequence for the host device ignoring outputted pulses while the

phase-Z is LOW-level before generating an absolute pulse train, and during other LOW-level duration of

the phase-Z signal.

Note 2: An absolute pulse train for single-turn encoder is outputted after around 1 ms of outputting

phase-Z signal.

Note 3: The servo-ON signal is unaccepted until completing the transmission of a set of absolute pulse

trains by the [absolute data request] signal.

Note 4: The [alarm 57] occurs if the single-turn encoder rotates more than 127 resolvable position while

the multi-turn counter is transmitting an absolute pulse train.

Acquiring multi-turn count

For FWD revolution of the encoder (motor), the phase-A signal has 90 degree phase shift against

phase-B signal, and for REV revolution the phase-A signal has 90 degree phase delay against phase-B

signal as shown below.

Increasing or decreasing the multi-turn counter of the host device should be discriminated by the phase

shift or delay of phase-A against phase-B. Acquire the signal at rising edge of the signal

For FWD revolution of the encoder (motor), the phase-A signal has 90 degree phase shift against

phase-B signal, and for REV revolution the phase-A signal has 90 degree phase delay against phase-B

signal as shown below.

Increasing or decreasing the single-turn encoder counter of the host device should be discriminated by

the phase shift or delay of phase-A against phase-B. Acquire the signal at rising and falling edge of the

signal.

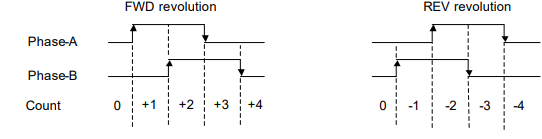

An example of signal transmission

The following is an example of the multi-turn count: 8, single-turn encoder count: 25 and an incremental

pulse train at a usual operation.

The actual resolvable position of the encoder (motor) can obtained by the calculation of:

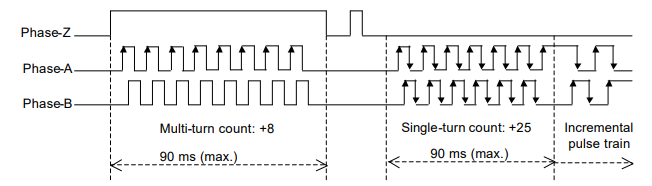

(b) Acquiring from CN3 port (RS-232C)

Connecter specifications

Connect an RS-232C cable having following specifications between the CN3 port of the HA-655 driver

and a RS-232C port of a host device.

Connecters: D-sub connecter having 9 female pins

Pin assignments:

Sending a command to HA-655 driver (host →HA-655)

The command should be 10 characters in length including a delimiter as illustrated below. The

HA-655 driver waits until receiving 10 characters without any processing. Make sure that the

message has 10 characters including a delimiter.

(1) The first function of the [position control block] is the [error count] calculation by the [error counter]

in the block subtracting a feedback count from a command count.

(2) The second function is the block that converts the [error count] to a [speed command] multiplying a

factor, and then transmits the [speed command] to the [speed control block]. The factor (Kp) is

called [position loop gain].

It is clear in the formula that a large [error pulse] is converted into a high [speed command] and a

zero pulse into a zero speed command, in other words, a stop command.

(3) If the [position loop gain (Kp)] is high, a small [error count] is converted into a higher [speed

command]. That is to say, higher gain provides the servo system with better response.

However, very high gain commands result in high [speed commands] from very minimal [error

count] which will result in overshooting. To compensate for the overshoot the [position control block]

generates a high speed reverse command, then overshoots in the opposite direction * * * finally

hunting motion may take place.

Conversely, if the [position loop gain (Kp)] is very low, you will get very slow positioning motion

(undershoot), and a poor servo response.

(4) In conclusion, it is important to set the optimum value to the [position loop gain (Kp)]. The HA-655

driver has been set with the most suitable value for general applications as a factory default. If the

load inertia is very heavy and the default is not suitable, tune it carefully.

◆ [Speed control block], [speed loop gain], and [speed loop integral compensation]

(1) The first function of the [speed control block] is to subtract a feedback signal from a command

signal.

(2) The second function is the block converts the difference to a [current command] multiplies it by a

factor, and then transmits the [current command (I)] to the [power amplifier]. The factor (Kv) is

called [speed loop gain].

It is clear in the formula that a significant [speed difference] is converted into a high [current

command] and zero difference into zero current command, in other words, a stop command.

(3) Just as with the [position loop gain], higher gain provides better response and excessive gain

results in hunting. Low gain requires no hunting but raises the occurrence of undershoots.

(4) The [speed loop integral compensation (Tv)] of The HA-655 driver makes less influence on load

fluctuation.

If the [speed loop integral compensation (Tv)] is smaller, the speed response to the load fluctuation

becomes better, but too small a value results in hunting. Excessive compensation requires no

hunting, but will result in a poor response for load fluctuation.

● Tuning method

[Tune mode]→[0.speed loop gain], and [1: speed loop integral compensation]

◆ Feed forward gain

(1) In the position mode The HA-655 driver controls the error count, (the difference between

[command pulse] and [feedback pulse]), to be [0]. At the beginning of inputting a command pulse

train, the actuator starts slowly because of small error count.

(2) The [feed forward] function may accelerate the actuator as much as possible, adding speed pulses

converted from the command pulse frequency directly to the driver’s speed control loop

) The relation between the feed forward and actuator motion is as follows:

Higher feeding allows for better following to command, but excessive feeding results in hunting and

erratic motion.

Low feeding requires no hunting but a poor following of the command.

● Tuning method

[Tune mode]→[3:Feed forward]

2-2-5 FWD inhibit and REV inhibit

The HA-655 driver provides [FWD inhibit] and [REV inhibit] input signal ports.

[FWD inhibit]: opening (OFF) the input inhibits forward rotation.

[REV inhibit]: opening (OFF) the input inhibits reverse rotation.

Opening (OFF) both inputs inhibits all rotation.

The inputs may be used to limit the motion range between limit sensors.

2-2-6 In-position

In the position mode, even though the driver controls the actuator to make the [error count 0], it is not

always possible due to the influence of external forces, acceleration, and deceleration. Establishing a

positioning allowance is a good solution to the problem; that is [in-position range].

[Tune mode]→[4: in-position range] sets the allowance. The actuator position comes within the range

calculated with the formula below, the [CN2-33: in-position] signal outputted.

2-3 Speed mode

The HA-655 driver makes use of either the position control or the speed control. This section describes

the speed mode. (※ The default setting is the [position mode].

Before running, set the control mode by [parameter mode] → [0: control mode].

2-3-1 Speed conversion factor

In the speed mode, the command is sent from a host with an analog voltage signal. The [speed

conversion factor] converts the [speed command] voltage to motor speed.

The [speed conversion factor] is the motor speed when the [speed command voltage] is [10V]. The

actual motor speed is obtained by the following formula:

The [speed monitor] (SPD-MON: CN2-23pin) output voltage as follows:

● Setting

[Parameter mode]→[9: speed conversion factor]

2-3-2 Voltage of speed command

Input the voltage converted by the [speed conversion factor] into [CN2-31: speed command] and

[CN2-32: speed command common] pins. The [speed command voltage] is obtained by [parameter

mode]→[9: speed conversion factor].

◆ FWD enable and REV enable

The HA-655 driver provides [FWD enable] and [REV enable] input ports. The rotary direction of the

actuator is decided by the polarity of [CN2-31: speed command SPD-CMD] and ON/OFF states of [FWD

enable] and [REV enable] as shown in the table below:

CN2-31 Speed cmd.: SPD-CMD +Command -Command

CN2-4 FWD enable: FWD-EN ON OFF ON OFF

CN2-5 REV enable: ON Zero clamp, zero speed REV rotation Zero clamp, zero speed FWD rotation

REV-EN OFF FWD rotation Zero clamp, zero speed REV rotation Zero clamp, zero speed

● Relating input pins

CN2-31: speed command, CN2-32: speed command common, CN2-4: FWD enable,CN2-5:REV enable

◆ Speed command offset

In the speed mode, the motor may rotate slightly in spite of a [0V] speed command voltage. This problem

may occur when the speed command voltage has an offset of a few milli-volts. This function removes the

slight rotation compensating the command voltage offset.

While inputting a [OV] command voltage adjust the speed command offset until the actuator stops

rotating.

[Speed command automatic offset] function is also provided.

● Setting

[Tune mode]→[9: speed command offset], [test mode]→[So: Speed command automatic offset]

In the figure, the closed loop of [speed control block]→[power amplifier]→[actuator]→[encoder]→[speed

control block] is called [speed loop].

The details of the loop are described as follows:

◆ [Speed control block], [speed loop gain], and [speed loop integral compensation]

(1) The first function of the [speed control block] is to subtract a feedback signal from a command

signal.

(2) The second function is when the block converts the difference to a [current command] multiplies it

by a factor, and then transmits the [current command] to the [power amplifier]. The factor (Kv) is

called [speed loop gain].

It is clear in the formula that a [speed difference] is converted into a high [current command], and a

zero difference into a zero current command, in other words, a stop command.

(3) If the [speed loop gain (Kv)] is high, a small [speed command] is converted into a higher [current

command]. That is to say, higher gain provides the servo system with a better response.

However, very high gain settings can cause a very high [current command] in response to a small

[speed command] which will result in overshooting. To compensate overshooting, the [speed

control block] generates a high speed reverse command, then ・・・・・・・・・finally hunting motion

may take place.

(4) Conversely, if the [speed loop gain (Kv)] is very low, you will get very slow positioning motion

(undershoot) and poor servo response.

(5) The [speed loop integral compensation (Tv)] of the HA-655 driver minimizes the influence of load

fluctuation.

If the [speed loop integral compensation (Tv)] is low, the speed response to the load fluctuation

becomes better, but very small value can result in hunting. Excessive compensation requires no

hunting but a poor response for load fluctuation.

● Setting

[Tune mode]→[0: speed loop gain], [1: speed loop integral compensation]

2-3-4 Command change

The function can operate the actuator without command at the speed specified by [tune mode]→[6:

internal speed command]. This is convenient for diagnosis and for test operation without hosts.

The actuator will rotate at the speed set by the [internal speed command] when a signal is input to

CMD-CHG (CN2-6) and stops when the signal is removed.

● Relating I/O pin

Input pin: CN2-6

2-3-5 Acceleration / deceleration time constants

[Acceleration time constant] is the time it takes to accelerate the motor from [0 r/min] to the speed of [A:

speed limit] of [parameter mode].

[Deceleration time constant] is the time it takes to decelerate the motor from the speed of [A: speed limit]

of [parameter mode] to [0 r/min].

The deceleration time to speed command voltage is as follows:

2-3-6 Zero clamp

In the speed mode when [speed command] is [0], the actuator may rotate slightly by force from the

driven mechanism. The [Zero clamp] function forcefully stops the actuator when the speed command is

[0].

● Setting

[Parameter mode]→[7: zero clamp]

Take cares that the servo-lock function does not work and the

actuator is free to rotate when:

- main and/or control power are not supplied;.

- servo-ON signal is not inputted;

- an alarm occurs

2-4 Other functions

2-4-1 Indicating of pulse counts

As shown in the figure to the right, the motion

command pulses are transmitted to the HA-655

driver from a host. The driver drives the actuator

corresponding to the motion command. When the

actuator starts, the position pulses are sensed by

the encoder and are fed back to the driver. The

HA-655 driver continues to drive the actuator until

the error count (difference between command count

and feedback count) comes to zero.

In the monitor mode, [command pulse], [feedback pulse], and [error pulse] can be monitored. This

function may be effective for diagnosis.

● Indications

[Tune mode]→[3,4: error counter status], [7,8: feedback pulse], [9,A: command pulse]

2-4-2 Manual JOG operation

It is possible to operate the actuator manually for test, for tuning, and for diagnosis without commands

from a host. Pressing the [UP] and [DOWN] keys on the front panel rotates the actuator at pre-set speed

and at pre-set acceleration.

● Operation and setting

[Test mode]→[Jo: JOG operation], [SP: JOG speed], [Ac: JOG acceleration]

2-4-3 Monitoring inputs and operating outputs

It is possible to monitor input ports of [clear], [servo -ON], [FWD inhibit] and [REV inhibit] for test, for

tuning, and for diagnosis.

It is also possible to manually output signals of [in-position], [attained speed], [alarm] and so on without

relations to the actuator state by pressing the [UP] and [DOWN] keys on the front panel outputs signals.

● Operation and setting

[Test mode]→[b:I/O monitor], [InP:Output port operation]

Chapter 3 I/O ports

Through the CN2 connector (50 pins; half pitch) the HA-655 driver communicates with a host. Details of

the I/O ports are described in this chapter.

As the functions of the pins of the connector differ in each control mode, the functions are described

separately by modes.

3-1 Position mode

3-1-1 I/O port layout

3-1-3 I/O port connections in the position mode

This section describes the connection between the I/O ports and a host in the position mode

Inputs:

The HA-655 driver provides six ports

for inputs as shown in the figure to the

right.

◆ Specifications

Voltage: DC24V±10%

Current: 20mA or less

(for each port)

An input port circuit is shown in the

figure to the right. The ports marked

with (*) are available for absolute

encoder system only.

● Connection

The HA-655 driver does not provide

the power supply for input signals.

Connect a [+24V] power supply for the

signals to [CN2-1: input signal

common].

Outputs:

The HA-655 driver provides eight ports

for outputs as shown in the figure to

the right.

◆ Specifications

Port: Open collector

Voltage: DC24V or less

Current: 40mA or less

(for each port)

All ports are insulated by opto-isolators.

An output port circuit is shown in the

figure to the right.

3-1-4 I/O port functions in the position mode

This section describes I/O port functions in the position mode.

CN2-1 Input signal common: IN-COM (input)

● Function

This is the common port for inputs: [CN2-2, -3, -4, -5, -10, -11]. Supply external power for inputs to this

the port.

● Connection

Connect [+24V] external power supply for inputs here.

CN2-2 Clear: CLEAR (input)

● Function

(1) If alarm exists:

This clears the alarm state, returns to operable state, and clears the error count to [0]. For alarms

that cannot be cleared, shut off the control power once, and turn it on again.

(2) If no alarm exists:

This clears the error count to [0]. At the same time, this clears the command count and the feedback

count.

● Connection

Connect [NO-contact signal (a-contact)]. Refer to [CN2-1: input signal common].

CN2-3 Servo-ON: S-ON (input)

● Function

This turns the servo power for the HA-655 driver ON and OFF.

When the input is ON, the servo power of the HA-655 driver is ON and the actuator can be driven. When

OFF, the servo power turns OFF and the motor is free to rotate.

● Connection

Connect [NO-contact signal (a-contact)]. Refer to [CN2-1: input signal common].

CN2-4 FWD inhibit: FWD-IH (input)

CN2-5 REV inhibit: REV-IH (input)

● Function

[FWD inhibit]: open state (OFF) of the input inhibits forward rotation.

[REV inhibit]: open state (OFF) of the input inhibits reverse rotation.

Open states (OFF) of both inputs inhibit rotation.

The inputs may be used to limit the motion range between limit sensors.

.png)

.png)

.png)