ABBIndustrialIT Panel 800 - PP865 Version 5.1 Hardware and Installation

NOTICE

This document contains information about one or more ABB products and may include a

description of or a reference to one or more standards that may be generally relevant to

the ABB products. ABB may have one or more patents or pending patent applications

protecting the intellectual property in the ABB product(s) described in this publication.

The presence of any such description of a standard or reference to a standard is not a

representation that all of the ABB products referenced in this document support all of the

features of the described or referenced standard. In order to determine the specific features supported by a particular ABB product, the reader should consult the product specifications for the particular ABB product.

The information in this document is subject to change without notice and should not be

construed as a commitment by ABB. ABB assumes no responsibility for any errors that

may appear in this document.

In no event shall ABB be liable for direct, indirect, special, incidental or consequential

damages of any nature or kind arising from the use of this document, nor shall ABB be

liable for incidental or consequential damages arising from use of any software or hardware described in this document.

This document and parts thereof must not be reproduced or copied without written permission from ABB, and the contents thereof must not be imparted to a third party nor used

for any unauthorized purpose.

The software or hardware described in this document is furnished under a license and

may be used, copied, or disclosed only in accordance with the terms of such license.

This product meets the requirements specified in EMC Directive 89/336/EEC and in Low

Voltage Directive 72/23/EEC.

TRADEMARKS

All rights to copyrights, registered trademarks, and trademarks reside with their respective owners.

Copyright © 2005-2011 by ABB.

All rights reserved.

Release: December 2011

Document number: 3BSE043448R501

Section 1 Introduction

General

The Panel 800 operator panel is developed to satisfy the demands of humanmachine communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator panel work, for the most part, in an object-oriented way, making it

easy to understand and use. The configuration operation of the panel is made in a

personal computer, using the configuration tool Panel Builder 800. The project is

then transferred and stored in the operator panel.

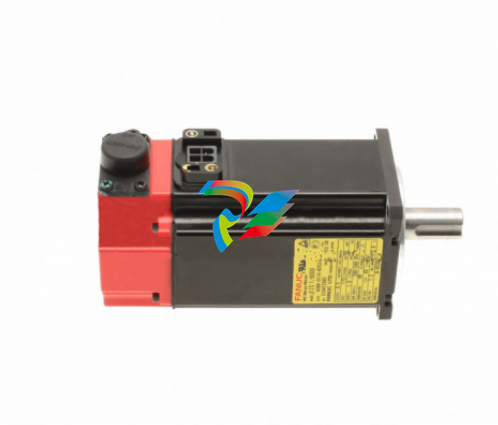

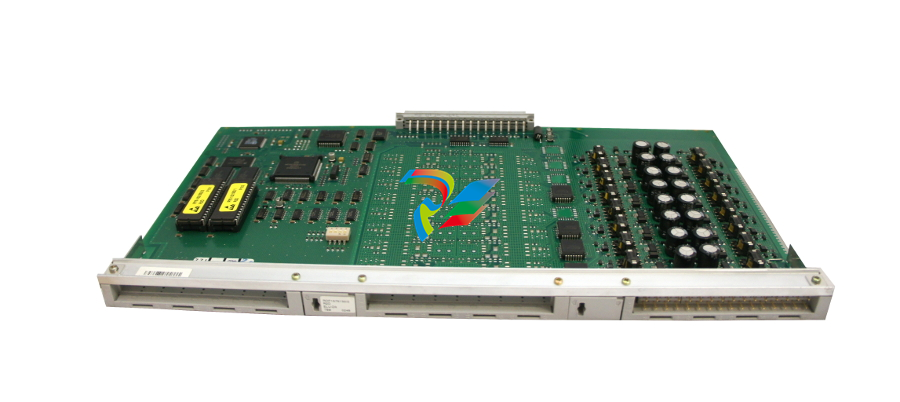

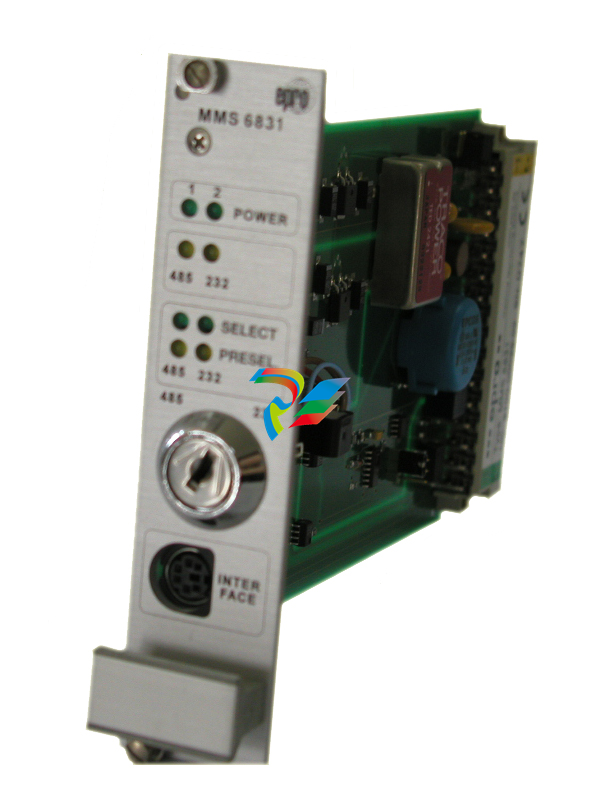

The operator panel can be connected to many types of automation equipment, such

as PLCs, servos or drives. In this manual the expression “the controller“ is used as a

general term for the connected equipment.

This manual explains how to install the operator panel. Please refer to the manual

Panel Builder 800, Programming and Installation (3BSE043445Rxxx) for further

information.

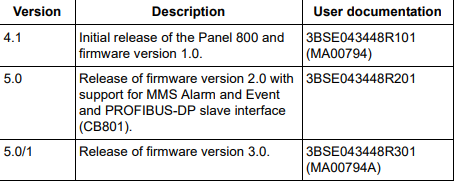

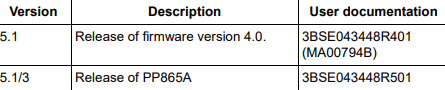

The release history of the Panel 800 is presented below.

Warning, Caution, Information, and Tip Icons

This publication includes Warning, Caution, and Information where appropriate

to point out safety related or other important information. It also includes Tip to

point out useful hints to the reader. The corresponding symbols should be

interpreted as follows:

Although Warning hazards are related to personal injury, and Caution hazards are

associated with equipment or property damage, it should be understood that

operation of damaged equipment could, under certain operational conditions, result

in degraded process performance leading to personal injury or death. Therefore,

fully comply with all Warning and Caution notices.

5.1 Release of firmware version 4.0. 3BSE043448R401

(MA00794B)

5.1/3 Release of PP865A 3BSE043448R501

Electrical warning icon indicates the presence of a hazard which could result in

electrical shock.

Warning icon indicates the presence of a hazard which could result in personal

injury.

Caution icon indicates important information or warning related to the concept

discussed in the text. It might indicate the presence of a hazard which could

result in corruption of software or damage to equipment/property.

Information icon alerts the reader to pertinent facts and conditions.

Tip icon indicates advice on, for example, how to design your project or how to

use a certain function

Section 2 Safety Precautions

Both the installer and the owner and/or operator of the operator panel must read and

understand this installation manual.

UL and cUL Installation

• This equipment is suitable for use in Class I, Division 2, Groups A, B, C and D

OR non-hazardous locations only. [Combinations of equipment in your system

are subject to investigation by the local Authority Having Jurisdiction at the

time of installation].

• Maximum ambient temperature 40 °C when mounted horizontal or 50 °C when

mounted vertical.

• WARNING – EXPLOSION HAZARD – Do not disconnect equipment unless

power has been removed or the area is known to be non-hazardous.

• For Canada also AVERTISSEMENT – RISQUE D’EXPLOSION – AVANT

DE DECONNECTER L’EQUIPEMENT, COUPER LE COURANT

OUS’ASSURER QUE L‘EMPLACEMENT EST DESIGNE NON

DANGEREUX.

• WARNING – EXPLOSION HAZARD - Substitution of components may

impair suitability for Class I, Division 2.

• For Canada also AVERTISSEMENT – RISQUE D’EXPLOSION – LA

SUBSTITUTION DE COMPOSANTS PEUT RENDRE CE MATERIEL

INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I, DIVISION

2.

• WARNING – EXPLOSION HAZARD – only UL and cUL approved

expansion units are allowed to be connected to the port designated

“EXPANSION”. At the moment there are no such units evaluated or allowed.

• WARNING – EXPLOSION HAZARD - Do not replace expansion unit unless

power has been switched off or the area is known to be non-hazardous.

• This product contains battery, this must only be changed in an area known to be

non-hazardous. Permitted types are shown in the Section 4, Technical Data.

• For use on a flat surface of a type 4X enclosure indoor use only.

• To make wiring connections to the power supply connector, use an AWG 28-12

cable and a tightening torque of min. 0.5 Nm.

General

• Read the safety precautions carefully.

• Check the delivery for transportation damage. If damage is found, notify the

supplier as soon as possible.

• Do not use the operator panel in an environment with high explosive hazards.

• The supplier is not responsible for modified, altered or reconstructed

equipment.

• Use only parts and accessories manufactured according to specifications of the

supplier.

• Read the installation and operating instructions carefully before installing,

using or repairing the operator panel.

• Never allow fluids, metal filings or wiring debris to enter any openings in the

operator panel. This may cause fire or electrical shock.

• Only qualified personnel may operate the operator panel.

• Storing the operator panel where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to

congeal/become isotopic.

• The LCD display liquid contains a powerful irritant. In case of skin contact,

wash immediately with plenty of water. In case of eye contact, hold the eye

open, flush with plenty of water and get medical attention.

• The figures in this manual serves an illustrative purpose. Because of the many

variables associated with any particular installation, the supplier cannot assume

responsibility for actual use based on the figures.

• The supplier neither guarantees that the operator panel is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

During Installation

• The operator panel is designed for stationary installation on a plane surface,

where the following conditions are fulfilled:

– no high explosive risks.

– no strong magnetic fields.

– no direct sunlight.

– no large, sudden temperature changes.

• Install the product according to the accompanying installation instructions.

• Ground the product according to the accompanying installation instructions.

• Only qualified personnel may install the operator panel.

• Separate the high voltage, signal and supply cables.

• Make sure that the voltage and polarity of the power source is correct before

connecting the product to the power outlet.

• Peripheral equipment must be appropriate for the application and location.

During Use

• Keep the operator panel clean.

• Emergency stop and other safety functions may not be controlled from the

operator panel.

• Do not use too much force or sharp objects when touching the keys, display

etc.

Service and Maintenance

• Only qualified personnel should carry out repairs.

• The agreed warranty applies.

• Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

• Clean the display and surrounding front cover with a soft cloth and mild

detergent.

• Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier.

Dismantling and Scrapping

• The operator panel or parts thereof shall be recycled according to local

regulations.

• The following components contain substances that might be hazardous to

health and the environment: lithium battery, electrolytic capacitor and display.

Section 3 Installation

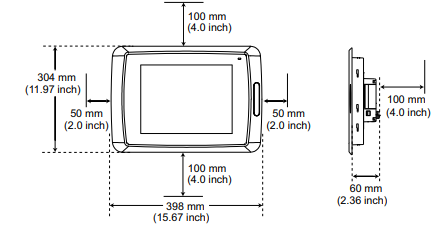

Space Requirements

• Installation plate thickness: 1.5 - 9.0 mm (0.06 - 0.35 inch)

• Space requirements when installing the operator panel:

The openings on the enclosure are for air convection. Do not cover these

openings.