A-B1326AB High Performance AC Servomotors

Basic Servomotor Description The 1326AB Servomotors are a family of high performance, three-phase, brushless AC synchronous motors designed by Allen-Bradley to meet the stringent requirements of servo system applications. This series of standard AC servomotors can be used with 1391 AC Servo Controllers. The performance parameters of these motors with selected amplifiers are listed on page 8. The typical speed-torque curves (see page 9) depict the operational envelope of these motor and controller combinations. Each motor has the following standard features:

• Permanent magnet rotor for increased servo response.

• Three-phase sinusoidal wound stator field for direct transfer of heat to ambient, and smooth operation at low speeds.

• Brushless resolver supplies position, commutation & velocity feedback information. This also provides durability in harsh environments by not having on-board electronics in the motor. 1391 A Quad B (optional) encoder output (up to 2048 ppr) is generated via resolver feedback.

• 100% continuous rated output torque at stall (zero rpm).

• Precision balance of 0.0005” (0.0127 mm) total peak-peak displacement.

• Vertical shaft up or down mounting.

• TENV construction.

• IP65 rated (when used with the Shaft Seal option) to withstand harsh environments. Motor is dust-tight and able to withstand pulsating water jets without liquid entering the motor. Important: 1326AB motors lose the IP 65 rating when externally mounted encoder/resolver feedback or blower packages are used.

• Normally closed thermal switch in the motor winding (rated 115V AC at 1A, 24V DC at 1A) provides thermal overload indication.

• Environmentally sealed power and feedback cable packages. Power and resolver feedback cables can be ordered as standard (flex), track (multi-flex) or extended length (ES).

• MIL spec connectors are standard.

• Ferrite magnets for cost effective performance.

• UL recognized insulation system (file # E57948).

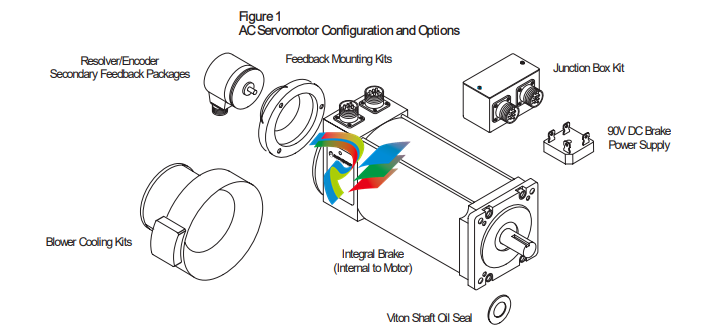

Options available for the 1326AB include (option code designation or catalog number in parenthesis):

• Integral spring-set holding brakes with 90V DC coils (-A4, -A5, -A7) or 24V DC coils (-K4, -K5, -K7).

• Brake Power Supply (1326-MOD-BPS) converts 115V AC to the voltage needed for 90V DC brakes (-A4, -A5 and -A7).

• Shaft Oil Seal kits (1326AB-MOD-SSV-xx) for field installation of Viton shaft seals. Motor disassembly is not required.

• NEMA Inch (-11) or IEC metric flange mount (-21) with metric shafts.

• Resolver Feedback Packages (1326AB-MOD-Vxxxx) provide 4.25” (108 mm) transducers which offer absolute/vernier or single brushless resolver feedback for use with Allen-Bradley 8600GP, IMC rack and S Class motion controllers. • Junction Box Kit (1326AB-MOD-RJxx) available with axially mounted connectors. Connector version allows the motor connectors to be brought out axially to the motor (rather than radially) without further wiring. • Secondary Feedback Mounting Kits (1326AB-MOD-Mx) for field installation of an Allen-Bradley Encoder (845H) or resolver. Using a 1326AB motor with a 1391B-ES (or 1391-DES) with A Quad B feedback (up to 2048 ppr) eliminates the need for encoder mounting. • Blower Cooling Kit (1326AB-MOD-G3, G4) provides air over cooling for up to 35% more torque output on most 1326AB “C” frame motors. The kit can be field mounted on the rear of 1326AB-Cxx motors (including motors with brakes). For motors using secondary motor mounted feedback (1326AB-MOD-M60), use option “G4.” • Cables for power (1326-CPxx . .) and feedback (1326-CFx . . - commutation, 1326-CEx . . - encoders) are available in lengths up to 100 ft .(30 m) for standard and high flex applications Power (1326ES-CPxx . .) and commutation (1326ES-CFx . .) cables over 100 ft. (30 m), up to 300 ft. (90 m) are available when using 1391B-ES or 1391-DES drives only. All kits are supplied as motor accessories and must be specified as a separate item.

Speed-Torque Curves Typical speed-torque curves for the standard 1326AB servomotors are contained on the following pages. Definitions of the terms used are provided below. Tc – rated torque of motor with windings at rated temperature and an ambient of 40°C. The controller is operating in a rated ambient of 60°C. Tp – the peak torque that can be produced by the motor/controller combination with both at rated temperature and the motor in a 40°C ambient and the controller in a 60°C ambient. Since 200% current torque peaks are common in many applications for optimal controller usage, the following curves show typical system performance. Higher peak torques are permissible where RMS torque is less than or equal to the rated torque (Tc). 1391B-ES/1391-DES operation is shown in the outer envelope and will show higher speed and 300% torque capability. Rated Speed – the operating speed of the controller and motor combination at which a minimum of 70% of continuous rated torque (Tc) can be developed. This point is defined with the motor at 25°C and controller operating in a 60°C ambient.

Rated Operation Area – boundary of speed-torque curve where the motor and controller combination may operate on a servo basis without exceeding the RMS rating of either. See page 31 for formula details.

Intermittent Operation Area – Boundary of speed-torque curve where the motor and controller combination may operate in acceleration-deceleration mode without exceeding peak rating of either, provided that the duty cycle RMS continuous torque limit is not exceeded. Continuous Current – Rated current of motor with windings at rated temperature and an ambient of 40°C. The controller is operating in a rated ambient of 60°C. Peak Current – The amount of current which can be applied to the motor without causing damage to the motor. Mechanical Time Constant – Time taken by the motor to reach 63% of final speed when a step voltage is applied. Electrical Time Constant – The time required for the motor to reach 63% of rated current. Max. Ambient Temperature – Maximum environmental temperature in which the motor can be operated at rated loads without exceeding its insulation type temperature rise limits. Insulation Class – Designation of operating temperature limits of the motor insulation materials. Thermal Time Constant – Time for motor windings to reach 63% of continuous temperature rise with constant watts loss. Torque Constant – At the stated motor temperature the amount of torque developed for one ampere of motor current. Voltage Constant – Value of the generated voltage at a specified speed when the rotor is moved mechanically in the magnetic field. Terminal Resistance – Winding resistance. Inductance – Winding inductance measured by a step input of zero impedance voltage applied to the locked rotor. Rotor Polar Moment of Inertia – Moment of inertia about the axis of rotation. Motor Weight – Weight of the complete motor (including brake, if supplied) less the weight of options. Balance – Compensation of rotor weight distribution to reduce vibrational resonance. Motors are factory balanced under running speeds

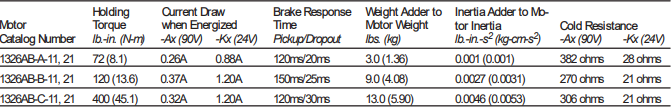

This section provides detailed information on the various options available for the 1326 AC Servomotor. Integral Holding Brake (Option -Ax or -Kx) The 1326AB servomotor contains an integral holding brake when the catalog number contains a suffix of “-Ax” (90V DC input) or “-Kx” (24V DC input). The brake is a disc type that is spring-set upon removal of power. The brake is designed to hold a load at rest and provide limited braking torque for emergency stopping. The brake is not intended as a positioning brake (brake backlash is 0.8 arc-minutes maximum) or to be continuously cycled to assist in stopping a load. When used as a parking brake, the brake must not be energized/de-energized more than 90 times an hour. A parking brake is only meant to hold a stationary load and is not intended to stop motor movement, unless a power interruption occurs. For further information, refer to Table B and the Bulletin 1391 Instruction Manual.

Brake Power Supply for 90V DC Brakes (1326-MOD-BPS) The Brake Power Supply converts 120V AC to the voltage needed for 90V DC brakes. Up to four brakes can be connected to one power supply. However, if independent control of multiple motors is desired, one power supply per motor must be used. Refer to Figure 13 for dimension and wiring information. Important: 24V DC brakes require a user supplied power supply capable of producing 24V DC at 0.88A to 1.2A. Specifications Power Supply Input Rating: 120V AC, single-phase, +10%, –15% Dissipation: 5 watts per motor

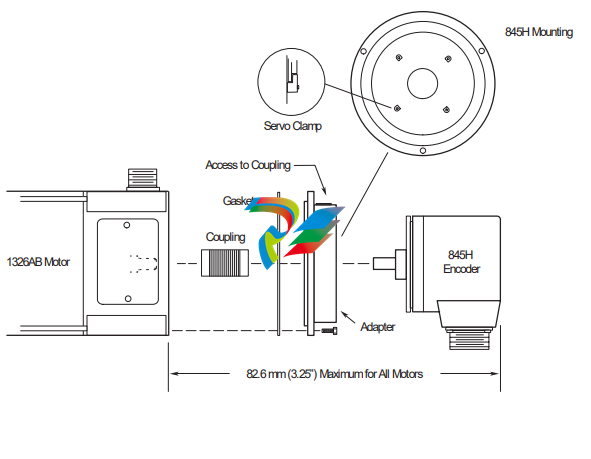

Encoder Mounting Adapters (1326AB-MOD-Mxx) Several adapters are available for mounting Allen-Bradley 845 H or T encoders to 1326AB Servomotors. Refer to the figure below for further information. Important: The IP 65 rating of the motor is not maintained when using this option.

Shaft Oil Seal (1326AB-MOD-SSV-xx) A Viton shaft oil seal is available for field installation on the motor shaft. The seal is to be used in applications where the motor shaft may be subjected to occasional oil splashes (motor is mounted to gearbox, etc.). The kit is not intended to be used in applications where the motor shaft is partially or fully submerged in oil.

Resolver Feedback Package (1326AB-MOD-Vxxxx) Figure 15 shows the dimensions of the 1326AB Resolver Feedback Package. Important: The IP 65 rating of the motor is not maintained when using this option.

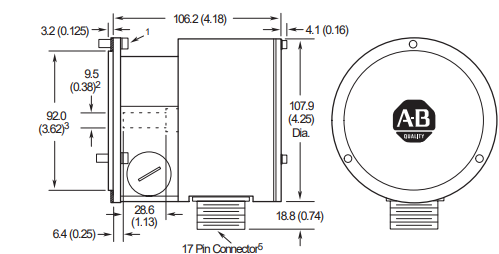

Figure 15 Resolver Feedback Package Dimensions

1 +0.000/–0.0127 (+0.0000/–0.0005) tolerance. 2 +0.000/–0.0762 (+0.0000/–0.003) tolerance. 3 All mounting hardware provided in Resolver Feedback Mounting Kit. 4 Cannon female connector CA3102R20–29P or equivalent mounted on the package. Cannon male mating connector CA3106F–20–295–A95 or equivalent. 5 Refer to the 1326AB Resolver Feedback Package Product Data for additional information.

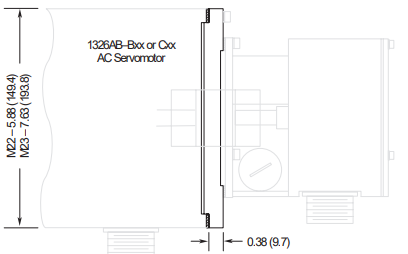

Resolver Feedback Mounting Adapter Kit (1326AB-MOD-Mx) The Resolver Feedback Mounting Kit provides a means of mounting the 1326AB Resolver to B and C series motors. An adapter is not needed for A series motors. Refer to Figure 16 for dimension information. Important: The IP 65 rating of the motor is not maintained when using this option. Figure 16 1326AB Resolver Mounting Kit Dimensions

1326AB–MOD–M22 or 1326AB–MOD–M23 Adapter for Mounting to 1326AB–Bxx or 1326AB–Cxx Motors, Respectively (Adaptor not required for 1326AB–Axx Motors)

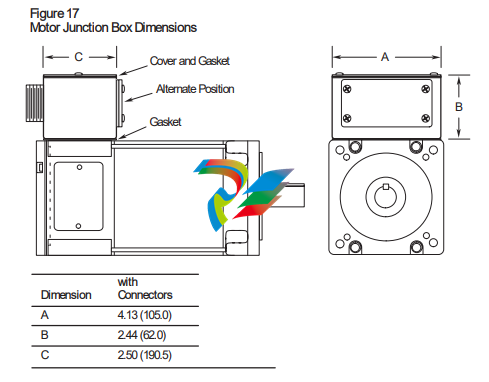

Motor Junction Box Kit (1326AB-MOD-RJxx) The Motor Junction Box Kit provides axially mounted connectors. The connector version allows the motor connectors to be brought out axially to the motor without further wiring. The IP65 rating of the motor is maintained when using this junction box. Dimensions for the junction box are shown in the following figure.

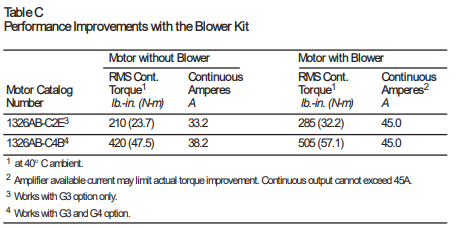

Blower Kits (1326AB-MOD-G3, G4) Two blower kits are available for use with 1326AB “C” Series AC Servomotors. The “G3” kit is designed for the “C2E” and “C4B” servomotors. The continuous current rating of all other “C” frame motors is too high to gain the benefit of the blower kit. The “G3” will not work on motors with a rear mounted encoder. The “G4” kit is designed for the “C4B” motor only. Each kit consists of an impedance protected fan (UL recognized, CSA approved), housing, grill guard and necessary hardware. Important: The IP 65 rating of the motor is not maintained when using this option. Specifications Input Voltage 220/240V AC, 50/60 Hz., single-phase Line Amperes 0.15 / 0.14 Locked Rotor Amperes 0.23 / 0.23 Fan Output 240 CFM Air Inlet Clearance 6 inches (152.4 mm) Weight 4 lbs. (1.81 kg) The following table illustrates the operational improvements realized when the blower kit is installed on the motors shown. Refer to Figure 18 for dimensions.

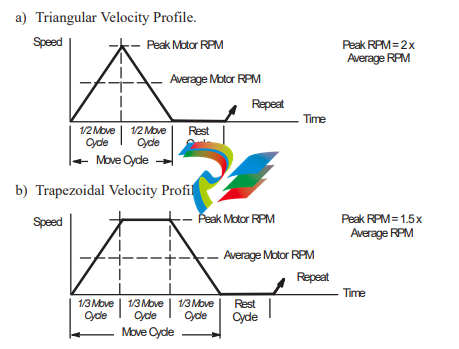

The following steps are a general guide designed to assist in servomotor selection. Formulas provided on the following pages should be used in conjunction with the steps below to determine correct motor sizing. For further assistance, complete the appropriate Application Data Sheet (pages 38-43) and contact your local Allen-Bradley Sales Office. 1. Determine the motor speed requirements. Based on the power train configuration of your application (leadscrew, rack and pinion, conveyor) determine the average and peak rpm of the servomotor. Choose the velocity profile that provides the closest approximation of your cycle.

2. Determine the minimum continuous motor torque required. Calculate motor torque (Tm) using the formulas on page 32, 34 or 36. 3. Determine the peak motor torque required to accelerate the load. If the motor must accelerate within a specified time, determine the system inertia using the formula sheets for your specific power train configuration, otherwise go to step 5. Use the time (Time) to achieve peak rpm, change in rpm (∆rpm), power train inertia (System Inertia) and load torque (Tl) in one of the two formulas that follow: System Inertia in lb.-ft.2 Peak Torque = System Inertia x ∆rpm 308 x Time (to accelerate) + Tl where: Peak Torque = total motor torque required to accelerate the load in lb.-ft. System Inertia = total system inertia (including motor) in lb.-ft.2 Time = acceleration time (in seconds) Tl = load torque present at the motor shaft during accel in lb.-ft. ∆rpm = change in motor velocity during acceleration time

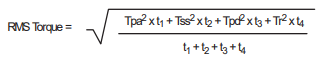

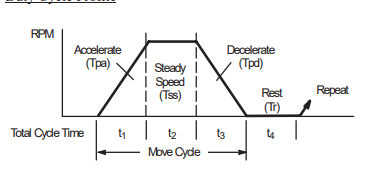

where: Peak Torque = total motor torque required to accelerate the load in lb.-in. System Inertia = total system inertia in lb.-in.-s2 (listed as Jtjm on formula sheets) Time = acceleration time (in seconds) Tl = load torque present at the motor shaft during accel in lb.-in. ∆rpm = change in motor velocity during acceleration time. 4. If the motors total time to accelerate/decelerate (t1 + t3) exceeds 20% of the total cycle time (t1+t2+t3+t4), determine the motors average torque with the formula shown

Trms The motors RMS or average torque over the duty cycle. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tpa Motor peak torque to accelerate to maximum speed. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tss Motor torque present at the motor shaft during constant speed segment. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tpd Motor peak torque to decelerate to zero speed. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tr Torque when motor is at zero speed (typically is Tss). t1, t2, t3, t4 Time for each portion of the duty cycle in seconds. Tpa2 x t1 + Tss2 x t2 + Tpd2 x t3 + Tr2 x t4 t1 + t2 + t3 + t4 Trms = 5. To select a servomotor: a) Select a motor with maximum speed capability of at least the peak rpm calculated in step 1. b) Select a motor with continuous torque capability equal to or greater than the value determined in step 2 or 4, whichever is greater. c) Select a motor with the capability to supply peak torque as determined in step 3, up to the maximum speed determined in step 1.

Servomotor Driven Leadscrew Formulas

Where: Notes: e = Efficiency of leadscrew, e1 (90% typical) or gearbox, e2 (95% typical). G.R. = Ratio of motor speed to leadscrew speed. Jb = Leadscrew inertia (lb.-in.-s2). Jgb = Gearbox inertia at the motor shaft (lb.-in.-s2). Jm = Motor inertia (lb.-in.-s2). Jtjm = Total system inertia at the motor shaft (lb.-in.-s2). Lead = Movement of slide in inches per revolution of leadscrew. Nm = Motor velocity (rpm)

Tb = Torque at leadscrew (lb.-in.). Thrust = Cutting force applied by slide/load on a workpiece (lbs). Tl = Load torque present at the motor shaft during accel (lb.-in.). Tm = Load torque required at the motor (lb.-in.). u = Table/slide sliding coefficient of friction (typically 0.03 to 0.2). V1 = Linear velocity of slide/load (IPM). W1 = Weight of slide and load (lbs.). θ = Angle of leadscrew position referenced from the horizontal axis (0°).

Notes: e = Efficiency of leadscrew, e1 (90% typical) or gearbox, e2 (95% typical). G.R. = Ratio of motor speed to leadscrew speed. Jb = Leadscrew inertia (lb.-in.-s2). Jgb = Gearbox inertia at the motor shaft (lb.-in.-s2). Jm = Motor inertia (lb.-in.-s2). Jtjm = Total system inertia at the motor shaft (lb.-in.-s2). Lead = Movement of slide in inches per revolution of leadscrew. Nm = Motor velocity (rpm). Tb = Torque at leadscrew (lb.-in.). Thrust = Cutting force applied by slide/load on a workpiece (lbs). Tl = Load torque present at the motor shaft during accel (lb.-in.). Tm = Load torque required at the motor (lb.-in.). u = Table/slide sliding coefficient of friction (typically 0.03 to 0.2). V1 = Linear velocity of slide/load (IPM). W1 = Weight of slide and load (lbs.). θ = Angle of leadscrew position referenced from the horizontal axis (0°). (1) Friction torque generated by the weight of the table/slide and part/tool. (2) Torque required for thrust (cutting force) load. (3) Friction torque generated by the thrust (cutting force) load (approximation). (4) Safety factor to account for torque required to overcome seals, gib adjustments, etc. (10% of Tm, min.). (5) This term is for a non-counterbalanced, non-horizontal axis. (6) System inertia should not exceed 5 times the motor inertia.

Typical Leadscrew Data (Using Formulas from Previous Page) Torque at Lead to Produce 1000 lbs. Thrust Force 1. Divide the lb.-in. value shown by efficiency of screw to obtain corrected value

Lead Torque (in./rev) (lb.-in.) 0.200 31.84 0.250 39.80 0.300 47.77 Lead Torque (in./rev) (lb.-in.) 0.333 53.02 0.500 79.61 1.000 159.23

. For thrust other than 1000 lbs. Torque = Required Thrust 1000 x Torque at 1000 lbs.

Inertia of the Leadscrew 1. To determine total leadscrew inertia.

eadscrew Inertia = Total Leadscrew Length (in.) 10 x Inertia (per 10” length) Diameter Inertia (10” length) (inches) (lb.-in.-s2 ) 0.50 0.000048 0.75 0.00023 1.00 0.00072 1.25 0.0018 1.50 0.0038 1.75 0.0068 Diameter Inertia (10” length) (inches) (lb.-in.-s2) 2.00 0.0115 2.25 0.0184 2.50 0.0281 2.75 0.0412 3.00 0.0583 3.50 0.1080

. Formula to determine leadscrew inertia. Jb = 0.000073(1) x D4 x L where: D = Screw diameter in inches. L = Screw length in inches. (1) Leadscrew is assumed to be made of steel. If it is made of aluminum, the 0.000073 constant becomes 0.000024.

Inertia of the Slide/Table Reflected to the Motor per 1000 lbs. Weight 1. For slide/table weight other than 1000 lbs.

Slide/Table Inertia at Leadscrew = Actual Weight 1000 x Reflected Inertia (1000 lbs.) Lead Reflected Inertia (per 1000 lbs.) (in./rev) (lb.-in.-s2) 0.200 0.0026 0.250 0.0042 0.300 0.0060 Lead Reflected Inertia (per 1000 lbs.) (in./rev) (lb.-in.-s2 ) 0.333 0.0074 0.500 0.0167 1.000 0.0666

Typical Rack & Pinion System Data (Using Rack and Pinion Formulas from Previous Page)

Torque at Pinion to Produce 1000 lbs. Thrust Force 1. Divide lb.-in. value shown at pinion by gearbox ratio and efficiency to obtain required motor torque (Tm) 2. To determine pinion torque for other thrust values, divide the thrust by 1000 and multiply by the pinion torque shown for the proper radius. Pinion Radius1 Pinion Torque (inches) (lb.-in.) 0.5 526.3 1.0 1052.6 1.5 1578.9 1 Pinion efficiency of 95% assumed. Pinion Radius1 Pinion Torque (inches) (lb.-in.) 2.0 2105.3 3.0 3157.9 4.0 4210.5

Torque at Pinion to Move 1000 lbs. Total Table/Slide Weight 1. Divide the lb.-in. value shown at pinion by gearbox ratio and efficiency to obtain required motor torque (Tm) 2. To determine pinion torque for other weight values, divide the weight by 1000 and multiply by the pinion torque shown for the proper radius.

Torque at Drive Pulley/Roller 1 w/1000 lbs. Load 1. Divide lb.-in. value shown at the roller by the gearbox ratio, roller/ belt (e1) and gearbox (e2) efficiency to obtain required motor torque (Tm) 2. To determine pulley/roller torque for other load values, divide the load weight by 1000 and multiply by the pulley/roller torque shown for the appropriate radius.

.png)

.png)