A-B1326AB High Performance AC Servomotors

Basic Servomotor Description The 1326AB Servomotors are a family of high performance, three-phase, brushless AC synchronous motors designed by Allen-Bradley to meet the stringent requirements of servo system applications. This series of standard AC servomotors can be used with 1391 AC Servo Controllers. The performance parameters of these motors with selected amplifiers are listed on page 8. The typical speed-torque curves (see page 9) depict the operational envelope of these motor and controller combinations. Each motor has the following standard features:

• Permanent magnet rotor for increased servo response.

• Three-phase sinusoidal wound stator field for direct transfer of heat to ambient, and smooth operation at low speeds.

• Brushless resolver supplies position, commutation & velocity feedback information. This also provides durability in harsh environments by not having on-board electronics in the motor. 1391 A Quad B (optional) encoder output (up to 2048 ppr) is generated via resolver feedback.

• 100% continuous rated output torque at stall (zero rpm).

• Precision balance of 0.0005” (0.0127 mm) total peak-peak displacement.

• Vertical shaft up or down mounting.

• TENV construction.

• IP65 rated (when used with the Shaft Seal option) to withstand harsh environments. Motor is dust-tight and able to withstand pulsating water jets without liquid entering the motor. Important: 1326AB motors lose the IP 65 rating when externally mounted encoder/resolver feedback or blower packages are used.

• Normally closed thermal switch in the motor winding (rated 115V AC at 1A, 24V DC at 1A) provides thermal overload indication.

• Environmentally sealed power and feedback cable packages. Power and resolver feedback cables can be ordered as standard (flex), track (multi-flex) or extended length (ES).

• MIL spec connectors are standard.

• Ferrite magnets for cost effective performance.

• UL recognized insulation system (file # E57948).

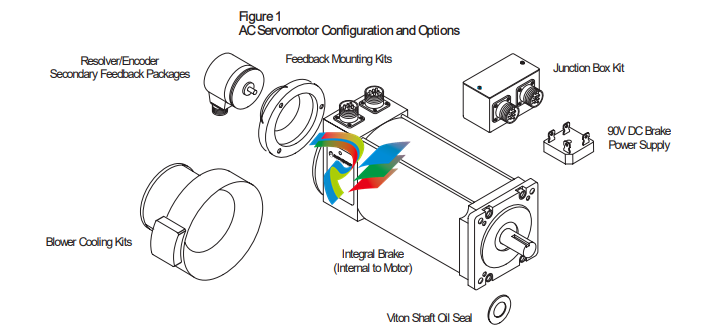

Options available for the 1326AB include (option code designation or catalog number in parenthesis):

• Integral spring-set holding brakes with 90V DC coils (-A4, -A5, -A7) or 24V DC coils (-K4, -K5, -K7).

• Brake Power Supply (1326-MOD-BPS) converts 115V AC to the voltage needed for 90V DC brakes (-A4, -A5 and -A7).

• Shaft Oil Seal kits (1326AB-MOD-SSV-xx) for field installation of Viton shaft seals. Motor disassembly is not required.

• NEMA Inch (-11) or IEC metric flange mount (-21) with metric shafts.

• Resolver Feedback Packages (1326AB-MOD-Vxxxx) provide 4.25” (108 mm) transducers which offer absolute/vernier or single brushless resolver feedback for use with Allen-Bradley 8600GP, IMC rack and S Class motion controllers. • Junction Box Kit (1326AB-MOD-RJxx) available with axially mounted connectors. Connector version allows the motor connectors to be brought out axially to the motor (rather than radially) without further wiring. • Secondary Feedback Mounting Kits (1326AB-MOD-Mx) for field installation of an Allen-Bradley Encoder (845H) or resolver. Using a 1326AB motor with a 1391B-ES (or 1391-DES) with A Quad B feedback (up to 2048 ppr) eliminates the need for encoder mounting. • Blower Cooling Kit (1326AB-MOD-G3, G4) provides air over cooling for up to 35% more torque output on most 1326AB “C” frame motors. The kit can be field mounted on the rear of 1326AB-Cxx motors (including motors with brakes). For motors using secondary motor mounted feedback (1326AB-MOD-M60), use option “G4.” • Cables for power (1326-CPxx . .) and feedback (1326-CFx . . - commutation, 1326-CEx . . - encoders) are available in lengths up to 100 ft .(30 m) for standard and high flex applications Power (1326ES-CPxx . .) and commutation (1326ES-CFx . .) cables over 100 ft. (30 m), up to 300 ft. (90 m) are available when using 1391B-ES or 1391-DES drives only. All kits are supplied as motor accessories and must be specified as a separate item.

Speed-Torque Curves Typical speed-torque curves for the standard 1326AB servomotors are contained on the following pages. Definitions of the terms used are provided below. Tc – rated torque of motor with windings at rated temperature and an ambient of 40°C. The controller is operating in a rated ambient of 60°C. Tp – the peak torque that can be produced by the motor/controller combination with both at rated temperature and the motor in a 40°C ambient and the controller in a 60°C ambient. Since 200% current torque peaks are common in many applications for optimal controller usage, the following curves show typical system performance. Higher peak torques are permissible where RMS torque is less than or equal to the rated torque (Tc). 1391B-ES/1391-DES operation is shown in the outer envelope and will show higher speed and 300% torque capability. Rated Speed – the operating speed of the controller and motor combination at which a minimum of 70% of continuous rated torque (Tc) can be developed. This point is defined with the motor at 25°C and controller operating in a 60°C ambient.

Rated Operation Area – boundary of speed-torque curve where the motor and controller combination may operate on a servo basis without exceeding the RMS rating of either. See page 31 for formula details.

.png)