A-B1326AB High Performance AC Servomotors

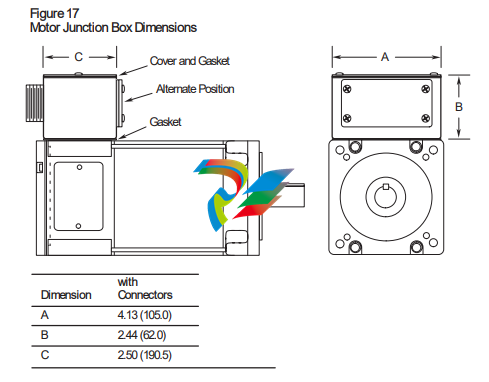

Motor Junction Box Kit (1326AB-MOD-RJxx) The Motor Junction Box Kit provides axially mounted connectors. The connector version allows the motor connectors to be brought out axially to the motor without further wiring. The IP65 rating of the motor is maintained when using this junction box. Dimensions for the junction box are shown in the following figure.

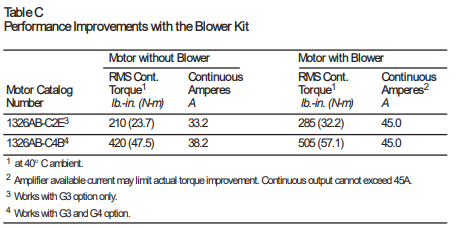

Blower Kits (1326AB-MOD-G3, G4) Two blower kits are available for use with 1326AB “C” Series AC Servomotors. The “G3” kit is designed for the “C2E” and “C4B” servomotors. The continuous current rating of all other “C” frame motors is too high to gain the benefit of the blower kit. The “G3” will not work on motors with a rear mounted encoder. The “G4” kit is designed for the “C4B” motor only. Each kit consists of an impedance protected fan (UL recognized, CSA approved), housing, grill guard and necessary hardware. Important: The IP 65 rating of the motor is not maintained when using this option. Specifications Input Voltage 220/240V AC, 50/60 Hz., single-phase Line Amperes 0.15 / 0.14 Locked Rotor Amperes 0.23 / 0.23 Fan Output 240 CFM Air Inlet Clearance 6 inches (152.4 mm) Weight 4 lbs. (1.81 kg) The following table illustrates the operational improvements realized when the blower kit is installed on the motors shown. Refer to Figure 18 for dimensions.

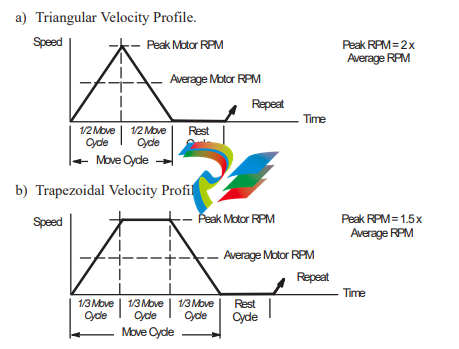

The following steps are a general guide designed to assist in servomotor selection. Formulas provided on the following pages should be used in conjunction with the steps below to determine correct motor sizing. For further assistance, complete the appropriate Application Data Sheet (pages 38-43) and contact your local Allen-Bradley Sales Office. 1. Determine the motor speed requirements. Based on the power train configuration of your application (leadscrew, rack and pinion, conveyor) determine the average and peak rpm of the servomotor. Choose the velocity profile that provides the closest approximation of your cycle.

2. Determine the minimum continuous motor torque required. Calculate motor torque (Tm) using the formulas on page 32, 34 or 36. 3. Determine the peak motor torque required to accelerate the load. If the motor must accelerate within a specified time, determine the system inertia using the formula sheets for your specific power train configuration, otherwise go to step 5. Use the time (Time) to achieve peak rpm, change in rpm (∆rpm), power train inertia (System Inertia) and load torque (Tl) in one of the two formulas that follow: System Inertia in lb.-ft.2 Peak Torque = System Inertia x ∆rpm 308 x Time (to accelerate) + Tl where: Peak Torque = total motor torque required to accelerate the load in lb.-ft. System Inertia = total system inertia (including motor) in lb.-ft.2 Time = acceleration time (in seconds) Tl = load torque present at the motor shaft during accel in lb.-ft. ∆rpm = change in motor velocity during acceleration time

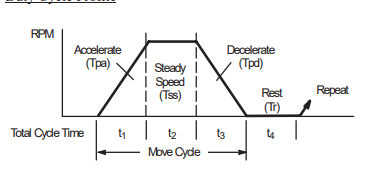

where: Peak Torque = total motor torque required to accelerate the load in lb.-in. System Inertia = total system inertia in lb.-in.-s2 (listed as Jtjm on formula sheets) Time = acceleration time (in seconds) Tl = load torque present at the motor shaft during accel in lb.-in. ∆rpm = change in motor velocity during acceleration time. 4. If the motors total time to accelerate/decelerate (t1 + t3) exceeds 20% of the total cycle time (t1+t2+t3+t4), determine the motors average torque with the formula shown

Trms The motors RMS or average torque over the duty cycle. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tpa Motor peak torque to accelerate to maximum speed. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tss Motor torque present at the motor shaft during constant speed segment. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tpd Motor peak torque to decelerate to zero speed. (Expressed in lb.-in. or lb.-ft. The same units must be used throughout the formula.) Tr Torque when motor is at zero speed (typically is Tss). t1, t2, t3, t4 Time for each portion of the duty cycle in seconds. Tpa2 x t1 + Tss2 x t2 + Tpd2 x t3 + Tr2 x t4 t1 + t2 + t3 + t4 Trms = 5. To select a servomotor: a) Select a motor with maximum speed capability of at least the peak rpm calculated in step 1. b) Select a motor with continuous torque capability equal to or greater than the value determined in step 2 or 4, whichever is greater. c) Select a motor with the capability to supply peak torque as determined in step 3, up to the maximum speed determined in step 1.

Servomotor Driven Leadscrew Formulas

Where: Notes: e = Efficiency of leadscrew, e1 (90% typical) or gearbox, e2 (95% typical). G.R. = Ratio of motor speed to leadscrew speed. Jb = Leadscrew inertia (lb.-in.-s2). Jgb = Gearbox inertia at the motor shaft (lb.-in.-s2). Jm = Motor inertia (lb.-in.-s2). Jtjm = Total system inertia at the motor shaft (lb.-in.-s2). Lead = Movement of slide in inches per revolution of leadscrew. Nm = Motor velocity (rpm)

Tb = Torque at leadscrew (lb.-in.). Thrust = Cutting force applied by slide/load on a workpiece (lbs). Tl = Load torque present at the motor shaft during accel (lb.-in.). Tm = Load torque required at the motor (lb.-in.). u = Table/slide sliding coefficient of friction (typically 0.03 to 0.2). V1 = Linear velocity of slide/load (IPM). W1 = Weight of slide and load (lbs.). θ = Angle of leadscrew position referenced from the horizontal axis (0°).

.png)