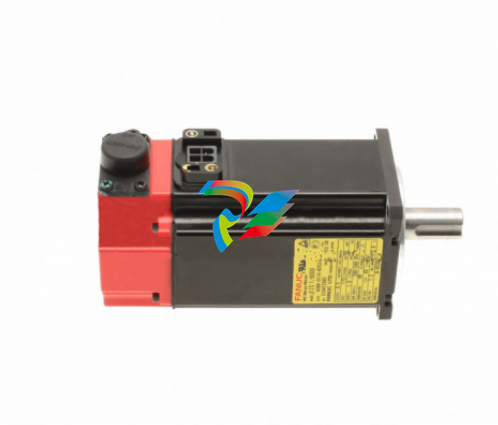

A-B1326AB High Performance AC Servomotors

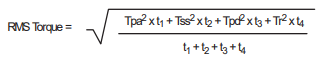

Intermittent Operation Area – Boundary of speed-torque curve where the motor and controller combination may operate in acceleration-deceleration mode without exceeding peak rating of either, provided that the duty cycle RMS continuous torque limit is not exceeded. Continuous Current – Rated current of motor with windings at rated temperature and an ambient of 40°C. The controller is operating in a rated ambient of 60°C. Peak Current – The amount of current which can be applied to the motor without causing damage to the motor. Mechanical Time Constant – Time taken by the motor to reach 63% of final speed when a step voltage is applied. Electrical Time Constant – The time required for the motor to reach 63% of rated current. Max. Ambient Temperature – Maximum environmental temperature in which the motor can be operated at rated loads without exceeding its insulation type temperature rise limits. Insulation Class – Designation of operating temperature limits of the motor insulation materials. Thermal Time Constant – Time for motor windings to reach 63% of continuous temperature rise with constant watts loss. Torque Constant – At the stated motor temperature the amount of torque developed for one ampere of motor current. Voltage Constant – Value of the generated voltage at a specified speed when the rotor is moved mechanically in the magnetic field. Terminal Resistance – Winding resistance. Inductance – Winding inductance measured by a step input of zero impedance voltage applied to the locked rotor. Rotor Polar Moment of Inertia – Moment of inertia about the axis of rotation. Motor Weight – Weight of the complete motor (including brake, if supplied) less the weight of options. Balance – Compensation of rotor weight distribution to reduce vibrational resonance. Motors are factory balanced under running speeds

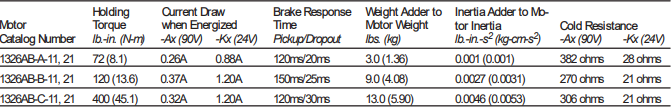

This section provides detailed information on the various options available for the 1326 AC Servomotor. Integral Holding Brake (Option -Ax or -Kx) The 1326AB servomotor contains an integral holding brake when the catalog number contains a suffix of “-Ax” (90V DC input) or “-Kx” (24V DC input). The brake is a disc type that is spring-set upon removal of power. The brake is designed to hold a load at rest and provide limited braking torque for emergency stopping. The brake is not intended as a positioning brake (brake backlash is 0.8 arc-minutes maximum) or to be continuously cycled to assist in stopping a load. When used as a parking brake, the brake must not be energized/de-energized more than 90 times an hour. A parking brake is only meant to hold a stationary load and is not intended to stop motor movement, unless a power interruption occurs. For further information, refer to Table B and the Bulletin 1391 Instruction Manual.

Brake Power Supply for 90V DC Brakes (1326-MOD-BPS) The Brake Power Supply converts 120V AC to the voltage needed for 90V DC brakes. Up to four brakes can be connected to one power supply. However, if independent control of multiple motors is desired, one power supply per motor must be used. Refer to Figure 13 for dimension and wiring information. Important: 24V DC brakes require a user supplied power supply capable of producing 24V DC at 0.88A to 1.2A. Specifications Power Supply Input Rating: 120V AC, single-phase, +10%, –15% Dissipation: 5 watts per motor

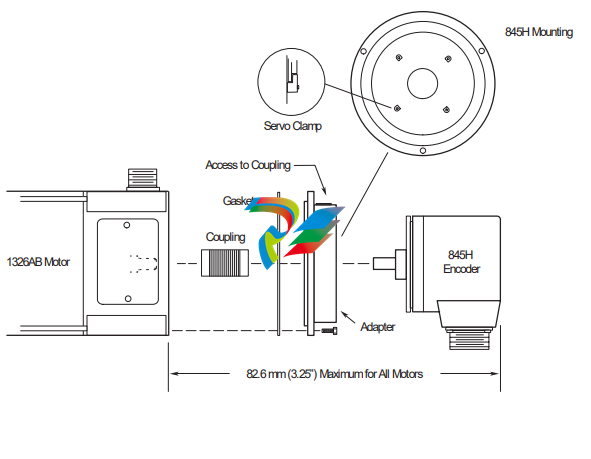

Encoder Mounting Adapters (1326AB-MOD-Mxx) Several adapters are available for mounting Allen-Bradley 845 H or T encoders to 1326AB Servomotors. Refer to the figure below for further information. Important: The IP 65 rating of the motor is not maintained when using this option.

Shaft Oil Seal (1326AB-MOD-SSV-xx) A Viton shaft oil seal is available for field installation on the motor shaft. The seal is to be used in applications where the motor shaft may be subjected to occasional oil splashes (motor is mounted to gearbox, etc.). The kit is not intended to be used in applications where the motor shaft is partially or fully submerged in oil.

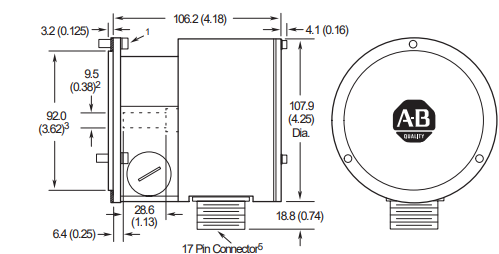

Resolver Feedback Package (1326AB-MOD-Vxxxx) Figure 15 shows the dimensions of the 1326AB Resolver Feedback Package. Important: The IP 65 rating of the motor is not maintained when using this option.

Figure 15 Resolver Feedback Package Dimensions

1 +0.000/–0.0127 (+0.0000/–0.0005) tolerance. 2 +0.000/–0.0762 (+0.0000/–0.003) tolerance. 3 All mounting hardware provided in Resolver Feedback Mounting Kit. 4 Cannon female connector CA3102R20–29P or equivalent mounted on the package. Cannon male mating connector CA3106F–20–295–A95 or equivalent. 5 Refer to the 1326AB Resolver Feedback Package Product Data for additional information.

Resolver Feedback Mounting Adapter Kit (1326AB-MOD-Mx) The Resolver Feedback Mounting Kit provides a means of mounting the 1326AB Resolver to B and C series motors. An adapter is not needed for A series motors. Refer to Figure 16 for dimension information. Important: The IP 65 rating of the motor is not maintained when using this option. Figure 16 1326AB Resolver Mounting Kit Dimensions

1326AB–MOD–M22 or 1326AB–MOD–M23 Adapter for Mounting to 1326AB–Bxx or 1326AB–Cxx Motors, Respectively (Adaptor not required for 1326AB–Axx Motors)