FIREYEDESCRIPTION AND INSTALLATION

IMPORTANT NOTE

The information provided in this bulletin is directed to competent boiler and combustion service

technicians who are experienced in the installation and operation of Fireye Flame Safety equipment.

Persons not familiar with Fireye products should contact the nearest Fireye representative or other

qualified service group.

The 45UV5 scanners as well as all other Fireye scanners, are designed to be used exclusively with

the appropriate Fireye Flame Safeguard and Burner Management controls. The application of these

scanners to other than Fireye equipment should be reviewed for approval by Fireye.

APPLICATION

Fireye 45UV5 self-checking scanners are used to detect ultraviolet emissions from fossil fuel flames

such as natural gas, coke oven gas, propane, methane, butane, kerosene, light petroleum distillates

and diesel fuels.

These 45UV5 models are used only with the Flame-Monitor, BurnerLogix, D-Series, FlameWorx,

MicroM and some P-Series Fireye control models to provide flame safeguard and monitoring systems for supervised manual, semi-automatic and fully automatic single burner boilers, process ovens

and heaters.

PRINCIPLES OF OPERATION

The 45UV5 scanners use a UV-eye detector. This detector is a sealed, gas filled, UV-sensitive tube

containing two electrodes connected to a source of AC voltage. When UV radiation of sufficient

energy falls upon the electrodes, electrons are released and the inter-electrode gas becomes conductive, resulting in an electric current flow from one electrode to the other. The current flow starts and

ends abruptly and is known as an “avalanche.”

A very intense source of UV radiation will produce several hundred avalanches or pulses per second.

With less radiation there will be fewer pulses per second. Upon total disappearance of flame, the

detector output ceases. Thus, the presence or absence of pulses is an indication of the presence or

absence of flame; the frequency of the pulses is a measure of flame intensity. Pulses generated by the

scanner are transmitted to a compatible Fireye control via scanner wiring.

FEATURES

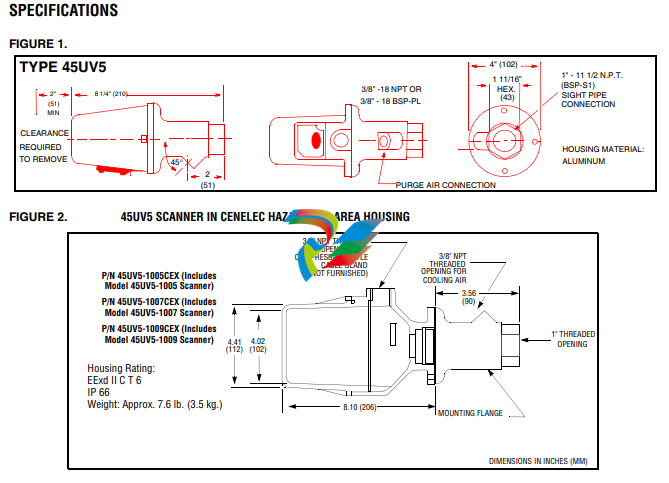

The components are contained in a cast aluminum housing sealed with an oil-resistant gasket. The

quartz lens is a planoconvex design, resulting in increased sensitivity. Also included in the scanner is

an electromagnetic shutter that permits a self-checking circuit to verify that the scanner and signal

circuits are producing valid flame presence or absence information. During the shutter closed period,

the detector’s optical path is blocked from flame radiation, allowing the amplifier control to verify

the proper operation of the ultraviolet tube. While the shutter is open, flame presence or absence is

detected. The resultant scanner output (while flame is detected) is a continuous, periodically interrupted, pulsed flame signal which is a prerequisite for energizing the associated Fireye control’s

Flame Relay.

1. AN ACCEPTABLE SCANNER LOCATION MUST ENSURE THE FOLLOWING:

— Reliable pilot flame detection.

— Reliable main flame detection.

— Rejection of pilot flame too short or in the wrong position to ignite the main flame reliably,

thus prohibiting main fuel admission.

NOTE: Reliable signals must be obtained at all air flows and furnace loads (ranges of fuel firing).

2. If combustion air enters the furnace with a rotational movement of sufficient velocity to deflect

pilot flame in direction of rotation, position the scanner 0 to 30 degrees downstream of the pilot

burner and close to the periphery of the throat where the ultraviolet radiation is at a maximum.

(See Figure 4).

3. Having determined an appropriate location for the sight tube, cut a clearance hole for a 2 inch

pipe through the burner plate. If register vanes interfere with the desired line of sight, the interfering vane(s) should be trimmed to assure an unobstructed viewing path at all firing levels, see

Figure 3.

4. Mount scanner sight pipe by either:

— Centering a Fireye No. 60-1664-3 (NPT) or 60-1664-4 (BSP) swivel mount over the hole

and installing the sight pipe on the swivel mount,

or

— Inserting the end of the sight pipe into the hole, aligning the pipe to the desired viewing

angle and tack welding. (Welding must be adequate to temporarily support the weight of the

installed scanner). The sight pipe should be arranged to slant downward so that the dirt and

dust will not collect in it.

When a satisfactory sighting position has been confirmed by operational test, (see section on

alignment), the sight pipe should either be firmly welded in place or, if the swivel mount is used,

the base position should be secured by tightening the three hex head cap screw located on the

swivel mount ring. In certain older style swivel mounts, tack welding may be required.

6. Excessive flame signal can affect flame discrimination and prevent the control connected to the

scanner from performing properly. To reduce the signal level of the tube, or improve flame discrimination, orifices may be installed to decrease the scanner’s field of view and reduce its sensitivity. Installation of the orifice disk is shown in Figure 6.

7. The scanner viewing window must be kept free of contaminants (oil, smoke, soot, dirt) and the

.png)