FIREYEDESCRIPTION AND INSTALLATION

scanner temperature must not exceed its maximum rating. Both requirements will be satisfied by

continuous injection of purge air.

The scanner mounting may be made with provision for purge air through the 3/8” opening as shown

in Figure 6, Item A or C, or through a 1" tee/wye connection as shown in Figure 6, Item B. Normally

only one of the two connections is provided with purge air and the other is plugged. When a Fireye

coupling is used as shown in Figure 6, the 1" tee/wye connection is used for the purge air (plug 3/8”

opening).

Under normal temperature conditions, with clean burning fuels and moderate ambient temperature

conditions, purge air flow of approximately 4 SCFM (113 L/min) is generally adequate. A 0.1 psig

positive pressure difference between the atmosphere and boiler pressure measured at right angle to the

purge air flow, should result in a purge air flow of 4 SCFM. Up to 15 SCFM (425 L/min) may be

required for fuels that may produce high levels of smoke of soot or for hot environments to maintain

scanner internal temperature within specifications.

NOTE: The maximum viewing field of the lens is one inch per foot. Do not use more than one foot of

one inch sight pipe. Increase sight pipe diameter one inch for every additional foot of sight pipe

length used, to avoid restricting the scanner’s field of view. Temperature in the scanner housing

should not exceed those temperature limits listed in the specifications. Excessive temperatures will

shorten scanner life.

CAUTION: Ultra-violet tubes can simulate flame when exposed to high levels of “X” and GAMMA

radiation. The table below indicates the maximum dose of radiation that a UV tube can be exposed to

safely.

SCANNER WIRING

All FIREYE controls are protected against short-circuited scanner input terminals. The following

recommendations apply for scanner control wiring:

• Keep scanner wiring as short as possible.

• Use wires rated for scanner voltage and its ambient conditions (temperature, humidity, oil resistant, flame retardant, etc.)

• Do not run scanner wires in the same conduit as other electrical wires.

• Avoid wire loops and poor groundings.

• Keep high voltage ignition wires well away from scanner wires.

The 45UV5 self-check scanner has four 6 foot (1800mm) leads:

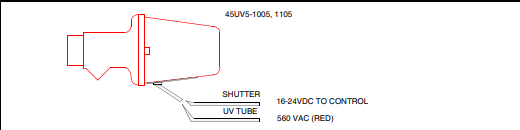

45UV5-1005 & 1105:

Two black leads which power the shutter from the associated control and two red leads which drive

the UV tube and carry the flame signal to the control amplifier.

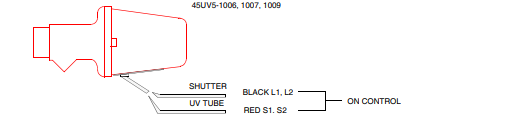

45UV5-1006, 1007 & 1009:

Two black leads which power the shutter via L1 & L2 and two red leads which drive the UV tube

and carry the flame signal to S1 & S2 on the control.

If it is necessary to extend the scanner wiring, the following instructions apply:

Scanner wires should be installed.in a separate conduit. The wires from several scanners may be

installed in a common conduit.

45UV5-1006, 1007, 1009.

1. Selection of wire

— Use #14, 16, or 18 wire with 75 C, 600 volt insulation for up to 100 foot distances (signal

loss approximately 20% at 100 feet).

— Asbestos insulated wire should be avoided.

— Multiconductor cable is not recommended without prior factory approval.

— Extended Scanner Wiring. For extended scanner wiring up to 1500 feet, and for shorter

lengths to reduce signal loss, use a shielded wire (Belden 8254-RG62U) coaxial cable, or

equal for each red wire of the 45UV5. The ends of the shielding must be taped individually

on both ends and not grounded.

For multiple burner installations:

2. Distances are decreased when more than one set of scanner leads are installed in a common conduit. For example, the maximum distance for 2 scanners is 750 feet and for 3 or more scanners

the distance decreases to 500 feet.

3. High voltage ignition wiring should not be installed in the same conduit with flame detector

wires.

WARNING: DO NOT CONNECT 45UV5 SCANNERS IN PARALLEL

45UV5-1005, 1105

1. Up to 25 foot conduit run.

— Use #18 AWG or heavier, 600V 90C minimum rated wire, installed in conduit.

2. Over 25 to 300 feet maximum:

— Use #18 AWG or heavier, 600V, 75C rated wire for the two black leads (shutter).

— Extended Scanner Wiring. For extended scanner wiring up to 1500 feet, and for shorter

lengths to reduce signal loss, use a shielded wire (Belden 8254-RG62U) coaxial cable, or equal

for each red wire of the 45UV5. The ends of the shielding must be taped individually on both

ends and not grounded.

For multiple burner installations:

3. Distances are decreased when more than one set of scanner leads are installed in a common conduit. For example, the maximum distance for 2 scanners is 750 feet and for 3 or more scanners the

distance decreases to 500 feet.

4. High voltage ignition wiring should not be installed in the same conduit with flame detector wires.

ALIGNMENT AND ADJUSTMENTS

The following procedures are recommended to ensure optimum flame detection and discrimination.

Flame discrimination is the ability to see only one burner or one pilot with other burners or pilots operating nearby. These procedures should be used whenever parts are replaced, when the scanner has been

moved, when the flame shape is altered (additional fuels, new burners, burner/register modifications)

.png)

.png)