GE Energy Mark* VIe Control Product Description

and are mounted on a DIN-rail. LEDs indicate the status of the IONet link, speed,

activity, and duplex.

100BaseTx 100BaseFx

IEEE specification 802.3u 802.3u

Wire speed 100 Mbps 100 Mbps

Cable type UTP Cat. 5 Fiber (multi-mode)

Connector type RJ-45 SC

Maximum length of a segment at full-duplex 100 m/328 ft 2 km/6,600 ft

Maximum taps per segment 2 2

Maximum I/O packs per network 199 199

Maximum number of switches 2 2

Topology Star Star

Operator and Maintenance Tools

Operator Interface

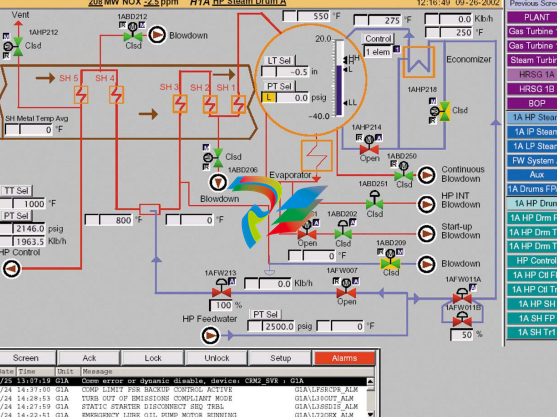

The operator interface is commonly referred to as the Human-Machine Interface

(HMI). It is a computer with a Microsoft® Windows-based operating system,

client/server capability, a CIMPLICITY® graphics display system, and software

maintenance tools (ToolboxST). It can be applied as:

• Primary operator station for one unit or the entire plant

• Maintenance station gateway

• Engineers station

• Gateway for communications

All local and remote data in

the Mark VIe is accessible for

screens with high-resolution

time tags for alarms and

events.

The HMI can be re-initialized or replaced with the process running with no impact

on the control system. It communicates with the main processor board in the Mark

VIe controller(s) through the control network Unit Data Highway (UDH) and to

third-party control and monitoring systems through the information network Plant

Data Highway (PDH).

System (process) alarms for fault conditions are time-tagged at frame rate in the

controller(s) and transmitted to the HMI alarm management system. System events

are time-tagged at frame rate, and sequence of events (SOE) for contact inputs are

time-tagged at 1 ms in the I/O packs. Alarms can be sorted according to ID,

Resource, Device, Time, and Priority. Operators can add comments to alarm

messages or link specific alarm messages to supporting graphics.

A standard alarm/event log stores data for 30 days and can be sorted in chronological

order or according to the frequency of occurrence. In addition, a trip history is

provided that stores the key control parameters and alarms/events for the last 30

trips. This includes up to 200 alarms, 200 events, 200 SOE messages, and analog

data before and after the trip.

Data is displayed in English or Metric engineering units with a one-second update

rate and one second to repaint a typical display graphic. Operator commands can be

issued to increment/decrement a setpoint, or a numerical value can be entered for a

new setpoint.

Security for HMI users is important to restrict access to certain maintenance

functions, such as editors and tuning capability, and to limit certain operations.

A system called User Accounts is provided to limit access or use of particular HMI

features.

Software Maintenance Tools (ToolboxST)

The Mark VIe is a fully programmable control system. Application software is

maintained by factory software automation tools that select proven GE control and

protection algorithms and integrate them with the I/O, sequencing, and displays for

each application. Multiple block libraries are provided with general-purpose blocks,

math blocks, macros (user blocks), and application-specific blocks.

Changes to the application software can be made with multi-level password

protection and downloaded to the controller(s) while the system is running without

rebooting the main processors. In redundant control systems, the application

software in each controller is identical, and is represented as a single program to

maintenance personnel. Downloads of changes are automatically distributed to the

redundant controllers by the control system, and any discrepancies between the

controllers are monitored by diagnostics. All application software is stored in the

controller(s) in non-volatile memory.

Application software is run sequentially, and dynamic data displays in function block

and ladder diagram formats. Maintenance personnel can add, delete, or change

analog loops, sequencing, I/O assignments, and tuning constants. To simplify

editing, data points can be selected, dragged, and dropped on the screen from one

block to another. Points can also be dragged from the application software diagrams

onto trends. Other features include Boolean (digital) forcing, analog forcing, and

trending at the rate the application software is running, frame rate.

Application software documentation is created directly from source code and can be

compiled and printed at the site. This includes the application software diagram, I/O

assignments, the settings of tuning constants, and such. The software maintenance

tools are available for use in the HMI or as a separate software package on a

Windows-based computer.

Diagnostics

High/low (hardware) limit checking is provided for each analog input. These limits