Ovation™ Controller Model OCR1100 (5X00481G04/5X00226G04)

partner is in control and assume the backup role. The

processor in control will detect the presence of the

backup processor and adjust for redundant operation.

Data Pass-Through

The OCR1100 controller is equipped with the ability to

pass smart field device information to any workstation

on the Ovation network. Users can take advantage of

asset management solutions, such as Emerson’s AMS

Suite, for remote management of intelligent field

devices.

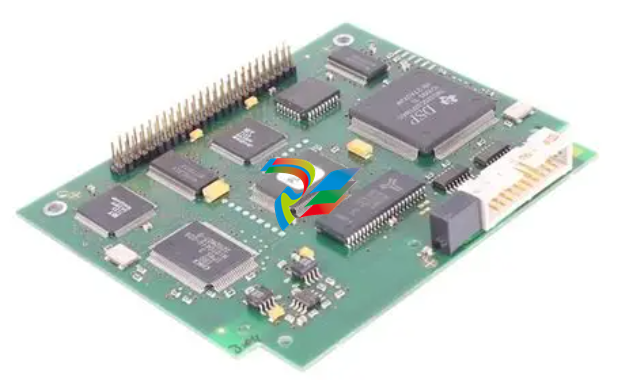

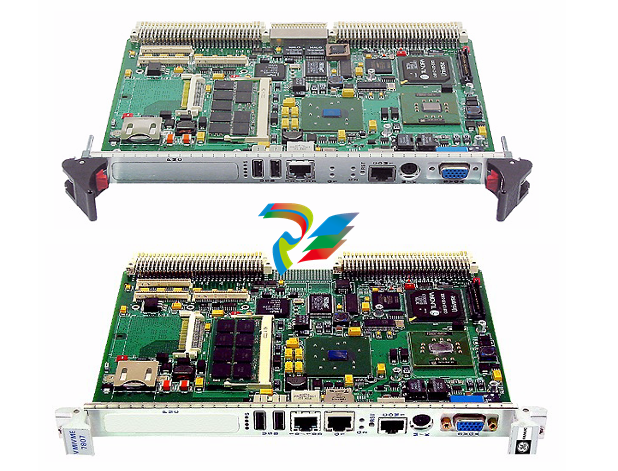

Open Architecture

The Ovation OCR1100 controller’s open architecture

uses a powerful real-time operating system running a

CompactPCI® i-bus PC design. This configuration

allows rapidly advancing technology to be easily

integrated into the control system while protecting

software investments.

Real-Time Operating

System Functions

The OCR1100 controller processes data for real-time

control and communication functions using a

commercially available, multi-tasking, real-time

operating system. It executes and coordinates the

control of multiple application areas by using multi

tasking with preemptive priority scheduling. The real

time operating system communicates with the Ovation

network and other systems via the TCP/IP protocol,

Page - 4

provides some basic routing functions and offers

general resource management within the controller.

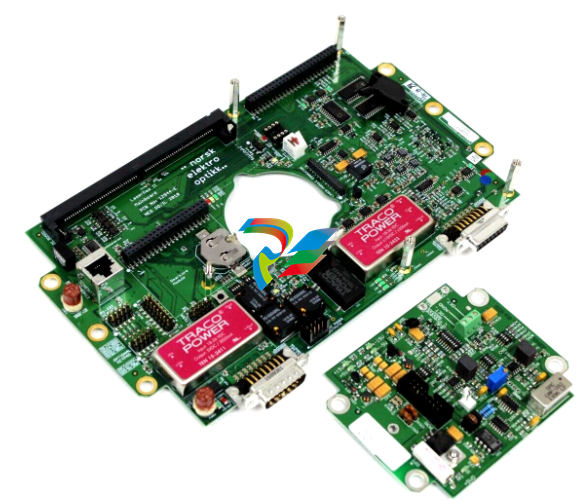

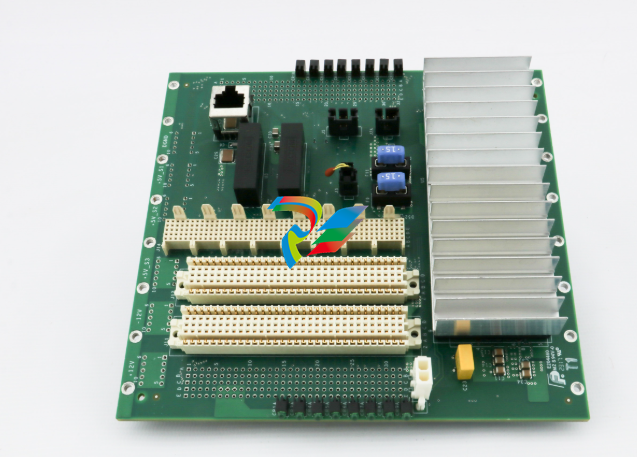

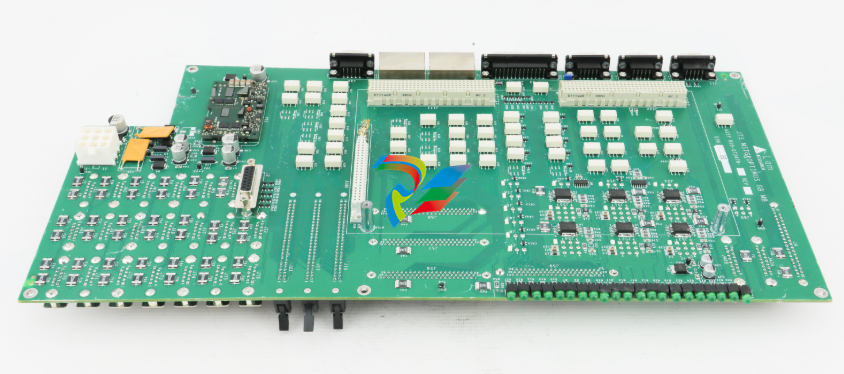

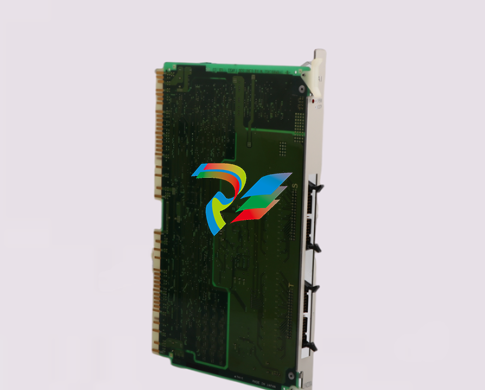

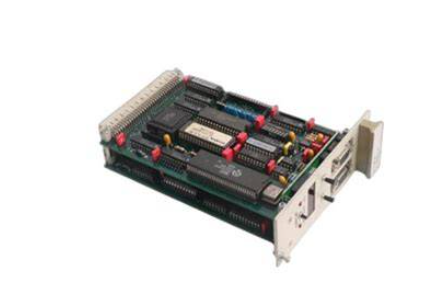

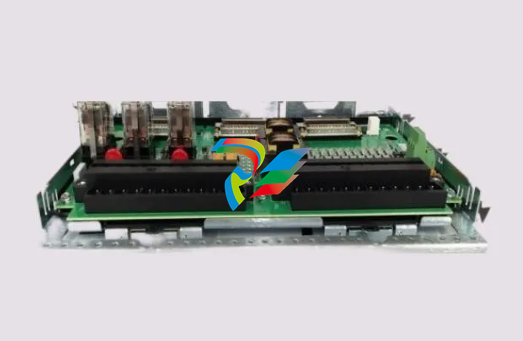

Hardware

The Ovation OCR1100 controller is built to open

industry standards using Intel processors and

CompactPCI bus technology. Newer technologies can

be easily incorporated while protecting the initial

Ovation controller software investment.

This foundation provides the portability such that

Ovation controller software can be run on other

available platforms and operating systems. The

Ovation virtual controller used in Ovation simulator

systems runs the standard Windows operating system

on standard PC hardware and does not require actual

I/O interfaces.

The hardware platform and the operating systems for

the Ovation controller, based on industry standards,

offer the following advantages:

Minimal cost and complexity of hardware and

software upgrades

Increased ability to track advances in technology

Specifications

The Ovation controller hardware platform has evolved

over time beginning with the OCR161 model.

Specifications for the OCR1100 model are detailed in

the tables within this document. The OCR1100

controller model shares the same packaging concept

as the preceding OCR400 model. Migration programs

are available to update previous model control logic

and databases to the latest model.

OCR1100 platform provides backward hardware

compatibility and can be used as an OCR400 while

retaining the ability to provide full OCR1100

capabilities when installed in an Ovation system

release which supports them (i.e. Ovation 3.5 and

above).

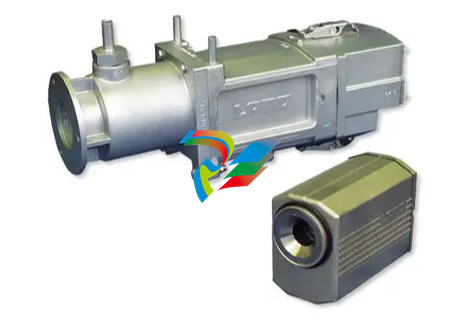

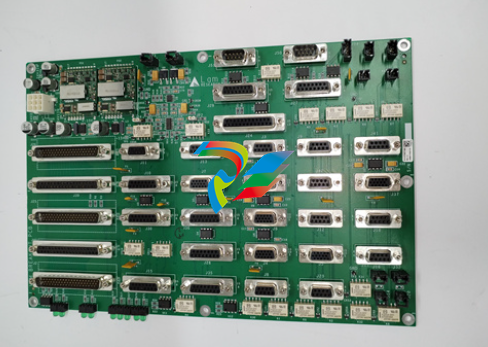

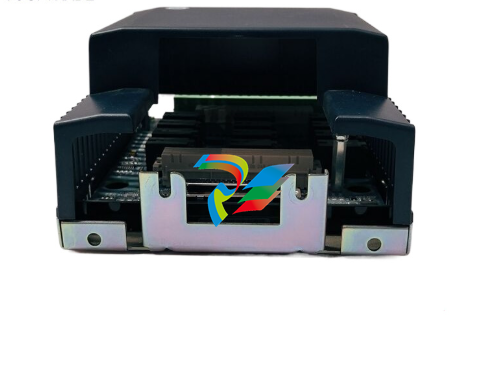

I/O Capabilities

The Ovation controller supports the concurrent use of

several I/O systems depending upon the model used.

Like the controller, the I/O system continues to evolve,

including support for increased channel capacity

modules. Refer to the controller hardware manual and

the I/O reference manual for additional details on the

available models, capacities, module capabilities and

termination types.

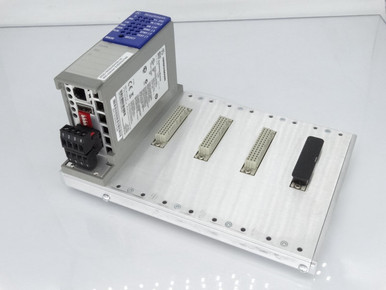

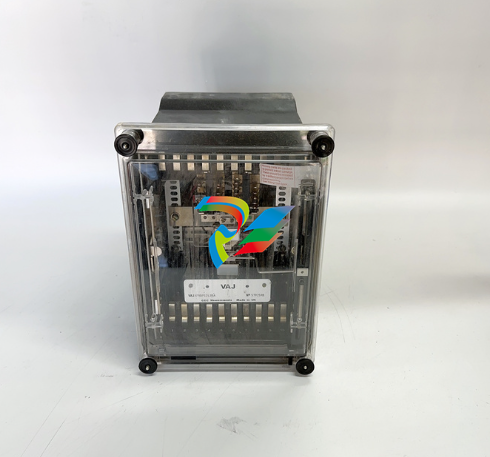

Ovation Controller Cabinets

Ovation controllers and I/O modules are all DIN rail

mountable, providing the flexibility to match controller

layouts with process requirements for various

locations, environments and space availability. The

normal configuration is to mount DIN rail items on

plates which can then be installed in existing or new

cabinet enclosures. Top and bottom entry for I/O

cables is available to meet required specifications.

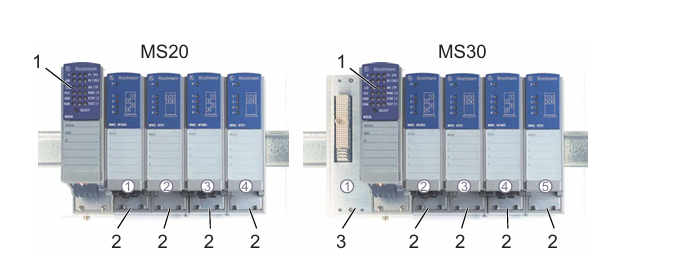

A variety of controller and I/O cabinet configurations

are available. The basic controller cabinet houses a

chassis for single or redundant controllers and two I/O

branches on the front of the plate. Mounted on the rear

of the plate is a redundant power supply, power

distribution module and two additional I/O branches for

a total of 32 I/O modules since each I/O branch can

hold up to eight I/O modules.

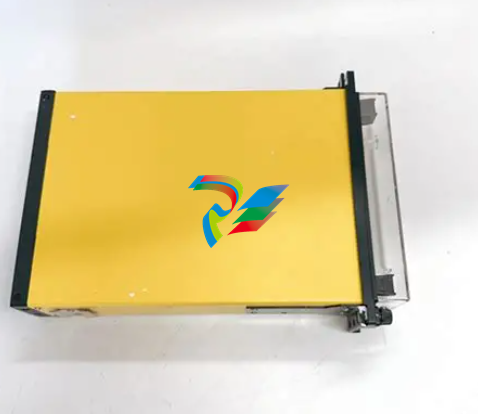

Expansion cabinets house up to an additional 32 I/O

modules in four branches and a transition panel for

connection to the controllers. It can also provide

additional space for mounting redundant power

supplies (when required), and a power distribution

module.

Ovation’s standard cabinet structure is front and rear

access, but can be provided with front access only.

Other custom or OEM cabinet enclosure