Ovation™ Controller Model OCR1100 (5X00481G04/5X00226G04)

Ovation™ Controller

Model OCR1100

(5X00481G04/5X00226G04)

Secure, reliable and mission-critical control

capability providing “bumpless” automatic failover

between redundant controllers.

Fast processor for increased productivity

One-step data acquisition functionality through the

definition of the I/O database

Small footprint with low power requirements and

fanless operation

Interfaces to Ovation and WDPF I/O, both local and

remote

Integral interface to digital busses through Ovation

I/O modules

Integrated virtual I/O capability for third-party OEM

systems over Ethernet protocols.

Non-volatile storage of application software, point

database, configuration information, and operating

tuning constants

Integrated sequence of events capability with 1

millisecond resolution

Meets IEC 61131-3 standards

Achilles Level 1 certified

Introduction

Emerson’s Ovation™ distributed control system is

renowned for delivering precision control with

outstanding performance. That precision begins with

the Ovation controller secure, mission-critical

operations such as those of power generation, water

and wastewater plants.

The OCR1100 model of the Ovation controller series

executes simple or complex modulating and

sequential control strategies, performs data

acquisition functions and interfaces to the Ovation

network and various I/O sub-systems. It has the

capability to originate up to 32.000 points.

Page - 1

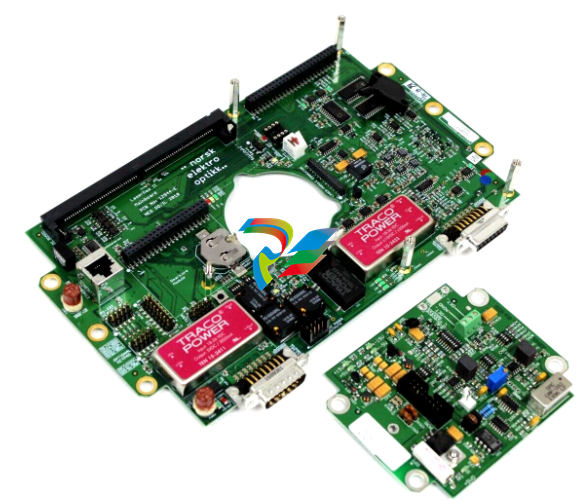

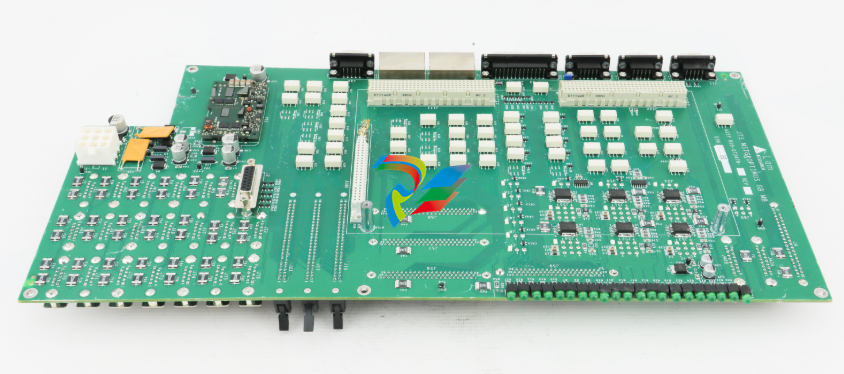

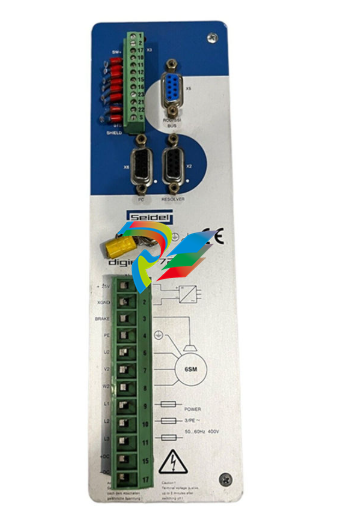

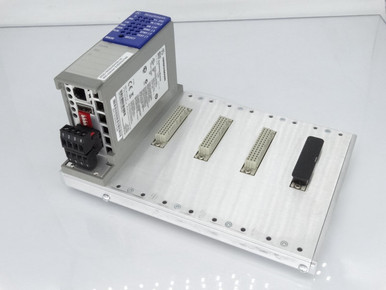

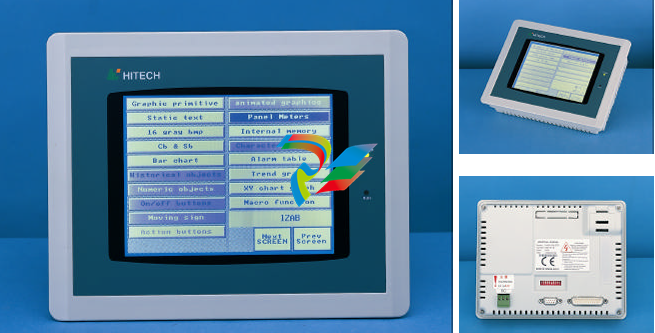

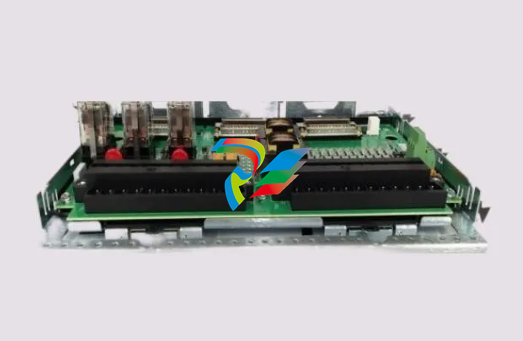

Redundant Ovation controller model OCR1100 shown with four

local Ovation I/O modules installed on two I/O branches.

Process Applications

The Ovation OCR1100 controller is designed to meet

the demanding requirements of a wide range of

process applications. Functions performed by the

controller include:

Continuous (PID) control

Boolean logic

Advanced control

Special logic and timing functions

Data acquisition

Sequence of events processing

Cold junction compensation

Process point sensor/limit checking

Process point alarm processing

Process point conversion to engineering units

Process point database storage

Local and remote I/O interface

Process point tagout

Standard Functions

Control Execution

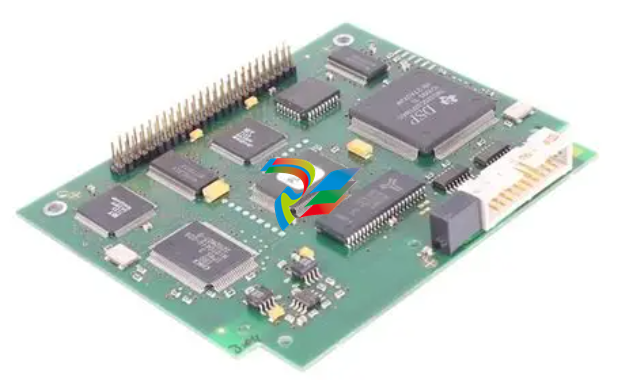

The Ovation OCR1100 controller, with an Intel®-based

processor, is capable of simultaneously executing as

many as five process control tasks at loop speeds

ranging from 10 milliseconds to 30 seconds. Each

control task is comprised of the I/O process point input

scan, control scheme execution and an output scan.

Two of the control tasks use predefined loops speeds

of one-second and 100 milliseconds. The other three

control tasks can have user-selectable loop speeds.

Individual control sheets assigned to an available task

coordinate the control execution loop time with the

appropriate control function. Advanced diagnostics

visible on Ovation HMI graphics indicate control task

loop times for configured, average, worst case and

standard deviation.

Control Scheme

OCR1100 functionality is defined by control sheets

created from an extensive library of standard and

advanced Ovation algorithms specifically designed for

the power, water and wastewater industries.

Control sheets provide the basis for executing,

documenting and automatically creating control

tuning diagrams used during commissioning and

when adjusting control schemes. On average, the

OCC100 controller can execute more than 1.000

control sheets.

Sequence-of-Events

Integral sequence-of-events processing capability is

provided using Ovation I/O and standard controller

software. With a resolution of one millisecond, the

sequence-of-events subsystem records the sequence

in which a set of user-defined digital input indications

change state, providing a valuable troubleshooting

and diagnostic tool for high-speed electrical systems.

Page - 2

In addition to the higher resolution time tags,

sequence-of-events points may be used in control

schemes like any other I/O point, including limit

checking and alarming.

Alarm Processing

The OCR1100 processes limits and alarms based on

each process point’s database definition. These

functions are performed regardless of whether the

point is scanned for input to a control loop or for data

acquisition separate from control functions. The alarm

status of each point in the controller is updated with

each scan. The status may indicate whether a point

value has:

Exceeded the range of the sensor

Exceeded the user-defined limits

Changed state

Passed an incremental limit

Alarm reporting can be delayed on a per-point basis by

a user-specified period.

When coupled with a workstation, the Ovation

OCR1100 controller has the capability to report six

independent alarm thresholds defined as:

Four high limits

User-defined high limit

Highest plus incremental limits

Four low limits

User-defined low limit

Lowest plus incremental limits

The workstation can sort and display alarms basedC

malfunction. A full range of events can trigger

automatic failover, including:

Control processor failure

Network controller failure

I/O interface failure

Removal of power from the control processor

Control processor reset

Once control is passed to the backup processor, the

failed processor may be powered down, repaired and

powered back up with no harmful effects on the

executing control strategy.

Upon restart, the repaired processor will detect that its

partner is in control and assume the backup role. The

processor in control will detect the presence of the

backup processor and adjust for redundant operation.

Data Pass-Through

The OCR1100 controller is equipped with the ability to

pass smart field device information to any workstation

on the Ovation network. Users can take advantage of

asset management solutions, such as Emerson’s AMS

Suite, for remote management of intelligent field

devices.

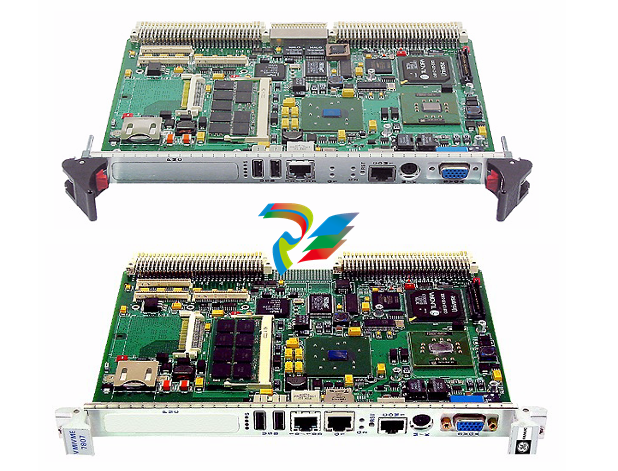

Open Architecture

The Ovation OCR1100 controller’s open architecture

uses a powerful real-time operating system running a

CompactPCI® i-bus PC design. This configuration

allows rapidly advancing technology to be easily

integrated into the control system while protecting

software investments.

Real-Time Operating

System Functions

The OCR1100 controller processes data for real-time

control and communication functions using a

commercially available, multi-tasking, real-time

operating system. It executes and coordinates the

control of multiple application areas by using multi

tasking with preemptive priority scheduling. The real

time operating system communicates with the Ovation

network and other systems via the TCP/IP protocol,

Page - 4

provides some basic routing functions and offers

general resource management within the controller.

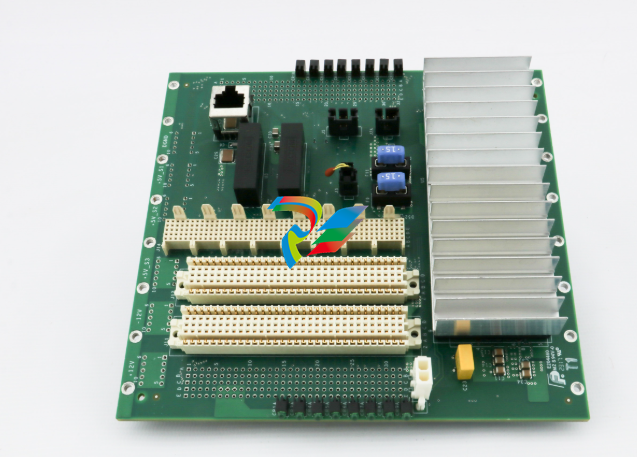

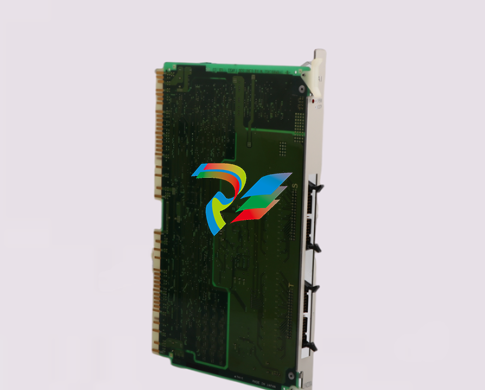

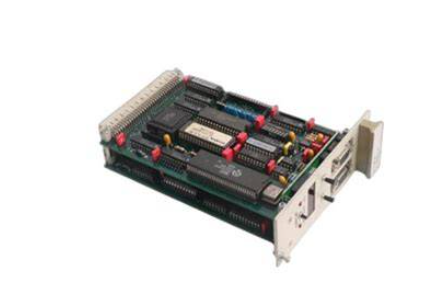

Hardware

The Ovation OCR1100 controller is built to open

industry standards using Intel processors and

CompactPCI bus technology. Newer technologies can

be easily incorporated while protecting the initial

Ovation controller software investment.

This foundation provides the portability such that

Ovation controller software can be run on other

available platforms and operating systems. The

Ovation virtual controller used in Ovation simulator

systems runs the standard Windows operating system

on standard PC hardware and does not require actual

I/O interfaces.

The hardware platform and the operating systems for

the Ovation controller, based on industry standards,

offer the following advantages:

Minimal cost and complexity of hardware and

software upgrades

Increased ability to track advances in technology

Specifications

The Ovation controller hardware platform has evolved

over time beginning with the OCR161 model.

Specifications for the OCR1100 model are detailed in

the tables within this document. The OCR1100

controller model shares the same packaging concept

as the preceding OCR400 model. Migration programs

are available to update previous model control logic

and databases to the latest model.

OCR1100 platform provides backward hardware

compatibility and can be used as an OCR400 while

retaining the ability to provide full OCR1100

capabilities when installed in an Ovation system

release which supports them (i.e. Ovation 3.5 and

above).

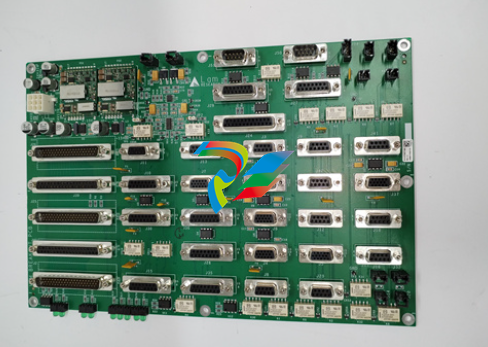

I/O Capabilities

The Ovation controller supports the concurrent use of

several I/O systems depending upon the model used.

Like the controller, the I/O system continues to evolve,

including support for increased channel capacity

modules. Refer to the controller hardware manual and

the I/O reference manual for additional details on the

available models, capacities, module capabilities and

termination types.

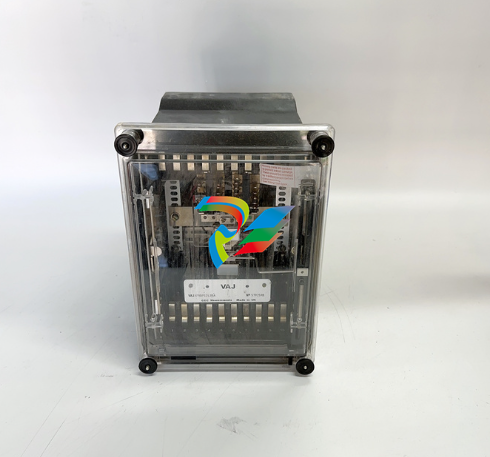

Ovation Controller Cabinets

Ovation controllers and I/O modules are all DIN rail

mountable, providing the flexibility to match controller

layouts with process requirements for various

locations, environments and space availability. The

normal configuration is to mount DIN rail items on

plates which can then be installed in existing or new

cabinet enclosures. Top and bottom entry for I/O

cables is available to meet required specifications.

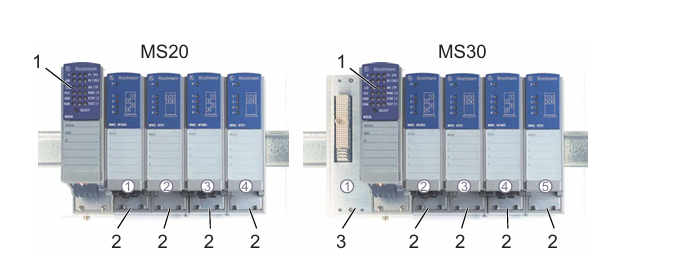

A variety of controller and I/O cabinet configurations

are available. The basic controller cabinet houses a

chassis for single or redundant controllers and two I/O

branches on the front of the plate. Mounted on the rear

of the plate is a redundant power supply, power

distribution module and two additional I/O branches for

a total of 32 I/O modules since each I/O branch can

hold up to eight I/O modules.

Expansion cabinets house up to an additional 32 I/O

modules in four branches and a transition panel for

connection to the controllers. It can also provide

additional space for mounting redundant power

supplies (when required), and a power distribution

module.

Ovation’s standard cabinet structure is front and rear

access, but can be provided with front access only.

Other custom or OEM cabinet enclosure