ABBDCS800 Quick guide DCS800 Drives (20 A to 5200 A)

ABB Drive Service EN

In order to offer the same after sales

service to our customer around the

world, ABB has created the DRIVE

SERVICE CONCEPT.

ABB's after sales service is globally

consistent due to common targets,

rules, and the way of operation. This

means for our customers:

Please visit the ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service FR

Pour offrir la même qualité de service

à tous nos clients, ABB a créé DRIVE

SERVICE CONCEPT.

Dans le monde entier, les équipes

de service proposent les mêmes

prestations aux mêmes conditions

avec les mêmes objectifs.

Pour en savoir plus, connectez-vous sur ABB drive service

homepage

www.abb.com/drivesservices

ABB Drive Service DE

Um jedem Kunden rund um die

Welt die gleiche Service Dienstleistung anbieten zu können, hat ABB

das DRIVE SERVICE CONCEPT

entwickelt.

Durch die Definition von einheitlichen

Zielen, Regeln, und Arbeitsvorschriften kann ABB die Dienstleitungs

Produkte weltweit auf gleichwertig

hohem Qualitätsniveau anbieten. Für

unsere Kunden bedeuted dies:

Bitte besuchen Sie die ABBHomepage Service für Antriebe

www.abb.com/drivesservices

ABB Drive Service IT

ABB ha creato il DRIVE SERVICE

CENCEPT, con lo scopo di offrire ai

nostri clienti lo stesso servizio post

vendita in tutto il mondo.

Attraverso la definizione di obbiettivi

comuni, ruoli e modo di operare, le

attività post vendita di ABB offrono

sevizi coerenti nella loro globalità. Per

i nostri clienti questo significa:

Vi invitiamo a visitare la homepage

ABB drive service

www.abb.com/drivesservices

ABB Drive Service ES

Para poder ofrecer el mismo servicio posventa a nuestros clientes

en todo el mundo, ABB ha creado

el CONCEPTO DE SERVICIO DE

CONVERTIDORES.

El servicio posventa de ABB está

mundialmente consolidado gracias

a unos objetivos y normas comunes,

así como a su funcionamiento. Esto

significa para nuestros clientes:

Visiten el portal de convertidores

de ABB

Standard Features

• compact

• highest power ability

• simple operation

• comfortable assistants, e.g. for autotuning or commissioning

• scalable to all applications

• free programmable by means of integrated IEC61131-PLC

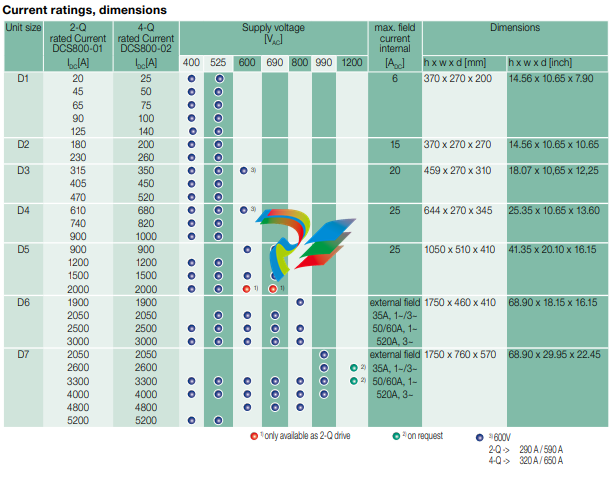

DCS800 DC Drives

Technical data

Mains supply volt. 230...1,200 V,

+/–10%, 3~

Frequency 50...60 Hz, +/–5

Hz

Electronics supply 115...230 V,

–15% / +10%, 1~

DC Output current 20...5,200 A

Overload capability 200%

Ambient conditions

Ambient temperat. 0° ... +40° C

40° ... 55°C with

reduction

Storage temperat. –40° ... +55° C

Transport temper. –40° ... +70° C

Relative humidity 5 ... 95%, not

condensing

(max. 50% betw.

0°...5° C)

Pollution degree Class 2

Protection class IP 00

Altitude < 1,000 m height

above sea level:

nominal Current

> 1,000 m height

above sea level:

with reduction

I/O

Digital inputs: 8 standard, up to

14 optional

Digital outputs: 8 standard, up

to 12 optional

Analog inputs: 4 standard +/–

10 V; 0/2…10 V, up to 8 optional

+/ 20 mA; 0/4…20 mA

Analog outputs: 3 standard (1x

I

act) +/-10 V; 0/2…10 V, up to 7

optional –20 mA; 0/4…20 mA

PC-Tools

DriveWindow Light: free of

charge with every converter,

Standard RS232 PC-connection

DriveWindow:Real-time optical

connection

ControlBuilder DCS800:

IEC61131 programming tool

DriveSize: Converter- and motor

dimensioning

Maintenance / Diagnosis

Remote diagnosis with any

Internet-PC worldwide

• with internet browser / internet

explorer

• or with DriveWindow full drive

control via OPC

High Current Solutions

• 12-pulse up to 20,000 A, serial

and parallel

• Hard parallel and sequential

• up to 1,500 V

Protections

Speed feedback monitoring •

Temperature • Overload • Over

speed • Motor stalled • Motor

over current • Motor over voltage

• Field over current • Field over

voltage • Minimum field current

• Zero speed • Armature current

ripple • Mains over- and under

voltage

Integrated IEC 61131-PLC

• Open standard programming

tool ControlBuilder DCS800

• Support of all five IEClanguages

• Drive-specific function blocks

• Saving of program and source

in Memory Card

• Online debugging and forcing

Approvals

Adaptive Programming

pre-defined drive-specific

function blocks, e.g.

• Free process controller (PIController)

• I/O- and digital Operations

With control panel or PC-Tool, no

need for additional hardware

Speed Feedback

EMF

Analogue tacho

Encoder

2nd Encoder possible (RTAC)

Communication

Serial communication

• Ethernet • Profibus

• CANopen • DeviceNet

• ControlNet • DDCS

• Modbus

• CS31 • AF100

• Selma2

Industrial IT© enabled

DCSLink Peer-to-Peer

• up to 800 kBaud, < 2.5 ms

• Master-Follower

• Armature-fieldconverter

• Free selectable data

Brief instructions for CD and documents overview

We appreciate that you purchased an ABB DC drive

power converter and thank you for the trust you put in our

products.

This brochure was put together to make sure that you continue