Summary of ABB TZIDC Electric Valve Positioner Selection Manual

# Summary of ABB TZIDC Electro-Pneumatic Valve Positioner Selection Manual

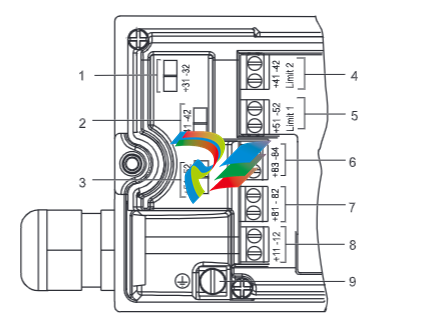

This document is a selection guide for ABB TZIDC series electro-pneumatic valve positioners, detailing the product's functional features, technical parameters, installation methods, communication capabilities, safety certifications, and ordering information. It is applicable to industrial control scenarios where positioners need to be configured for pneumatic actuators. ## I. Product Overview TZIDC is an electronically configurable intelligent valve positioner designed for pneumatic linear or rotary actuators. It features a **compact modular structure**, **high cost-performance ratio**, and **user-friendliness**. Its core advantages include automatic adaptation of control parameters, one-button commissioning, a wide temperature operating range, and multi-scenario explosion-proof certifications, making it suitable for industrial processes requiring precise valve control and safety redundancy. ## II. Core Functions and Features ### 1. Pneumatic Control - **Driving Method**: Converts electrical signals into pneumatic signals via an I/P module, combined with a pneumatic amplifier to control a 3/3-way valve, enabling continuous regulation of actuator pressurization/depressurization. After reaching the target position, the valve closes in the central position to reduce air consumption. - **Safety Functions**: - **Fail-safe**: In case of power failure, the actuator is depressurized, and the valve is driven to a preset safe position by a return spring (for single-acting actuators); for double-acting actuators, the second output is additionally pressurized. - **Fail-freeze**: In case of power failure, the output is closed, and the actuator maintains its current position; in case of air supply failure, the actuator is depressurized. ### 2. Operation and Commissioning - **Local Operation**: Equipped with a 2-line LCD display and 4 buttons, supporting parameter configuration, status monitoring, and manual control. The operation panel is protected by a cover to prevent misoperation. - **Convenient Commissioning**: Supports "one-button auto-adjustment" to start parameter adaptation with a single press (automatically adapts the zero position direction according to the actuator type), significantly simplifying the commissioning process. - **Parameter Configuration**: Allows setting of key parameters such as signal range (4-20mA, supporting split-range control), action direction (direct/reverse acting), characteristic curves (linear, equal percentage, etc.), travel limits, and alarm thresholds. ### 3. Communication Capabilities - **Standard Interface**: Equipped with an LKS local communication interface, supporting connection to a PC via an LKS adapter (RS-232 conversion). - **Optional HART Communication**: Enables HART protocol communication over the 4-20mA signal line via an FSK modem, supporting remote parameter setting, status monitoring, and diagnostics. - **Tool Support**: Compatible with FDT/DTM technology, it can be integrated into process control systems or configured via DSV401 (SMART VISION) software. Parameter modifications take effect in real-time and are stored in non-volatile memory. ## III. Technical Parameters | Category | Key Parameters | |-------------------------|--------------------------------------------------------------------------------| | **Input Signal** | 4-20mA two-wire system (minimum 3.6mA, maximum 25mA); digital input supports 11-30V DC logic signals | | **Output Signal** | Pneumatic output 0-6bar (single/double-acting); digital output complies with DIN 19234/NAMUR standard (5-11V DC) | | **Air Supply Requirements** | Clean, oil-free air (meets DIN/ISO 8573-1 Class 3), pressure 1.4-6bar, air consumption <0.03kg/h | | **Environmental Capability** | Operating temperature -40~85°C (for proximity switch SJ2-S1N: -25~85°C); relative humidity 95% (condensation allowed) | | **Housing and Protection** | Aluminum alloy material, protection class IP65/NEMA 4X; electrostatic spray coating (RAL 9005 black) | | **Safety Certifications** | Functional safety: SIL2 (complies with IEC 61508/61511-1); <br>Explosion protection: ATEX II 2G EEx ib IIC T6, FM/CSA Class I Div 1, etc. | | **Accuracy and Performance** | Characteristic deviation <0.5%; adjustable dead band 0.1-10%; sampling rate 20ms; vibration resistance <±1% (10g/80Hz) | ## IV. Installation and Adaptation Multiple installation methods are supported to adapt to different types of actuators: - **Linear Actuators**: Compliant with DIN/IEC 534 (NAMUR lateral mounting), requiring corresponding mounting kits. - **Rotary Actuators**: Compliant with VDI/VDE 3845, supporting a maximum rotation angle of 270°, with a shaft coupler to be ordered separately. - **Integral Mounting**: Directly mounted on control valves with internal mechanical connections, no external piping required. - **Special Actuators**: Customized installation solutions are available; contact the manufacturer for details. ## V. Optional Configurations and Accessories ### 1. Functional Expansion Options - **Feedback Modules**: Analog feedback (4-20mA), digital feedback (dual switching signals with adjustable thresholds). - **Safety Modules**: Emergency shutdown module (independent of the main board, drives the valve to a safe position when power is lost). - **Position Indicators**: Mechanical position indicator, proximity switches (SJ2-SN/S1N), 24V microswitches. ### 2. Key Accessories - **Mounting Kits**: Mounting brackets for linear/rotary actuators, shaft couplers, integral mounting accessories. - **Pneumatic Accessories**: Pressure gauge block (including air supply/output pressure gauges), filter regulator (brass material, 40μm filtration). - **Communication Tools**: LKS adapter (RS-232 conversion), FSK modem (HART communication), DSV401 configuration software. ## VI. Ordering Key Points The following key parameters must be clarified for selection: - Actuator type (single-acting/double-acting) and safety function (fail-safe/fail-freeze); - Communication options (standard LKS/optional HART); - Explosion-proof rating (select ATEX/FM/CSA certifications based on hazardous environments); - Installation method (linear/rotary/integral mounting); - Expansion functions (feedback modules, emergency shutdown modules, position indicators, etc.). Specific model codes consist of variant digits (actuator type, communication, explosion-proof rating, etc.), and accessories must be ordered separately (refer to detailed order numbers in the manual). ## Summary The ABB TZIDC positioner takes **high reliability**, **ease of use**, and **strong adaptability** as its core advantages. With a modular design supporting flexible expansion, it is widely used in valve control in industries such as petroleum, chemical, and power. Its wide temperature operating range, SIL2 safety certification, and multi-standard explosion-proof capabilities enable stable operation in harsh and hazardous environments. One-button commissioning and remote communication functions significantly reduce operation and maintenance costs.