Product Summary of ABB REF601/REJ601 Feeder Protection and Control Relay

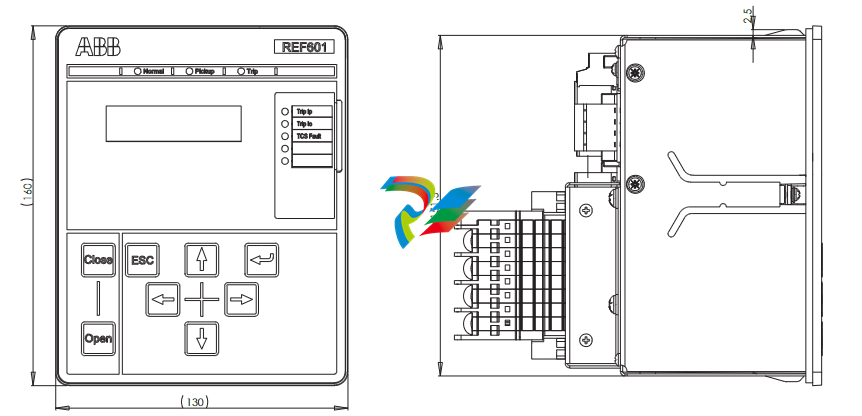

# Summary of ABB REF601/REJ601 Feeder Protection and Control Relay Product ## I. Product Overview REF601 and REJ601 are relays from ABB's Relion® 605 series, specifically designed for medium and low-voltage distribution network substations and industrial power systems. Among them, **REF601** is a dedicated feeder protection and control relay with circuit breaker control functionality, while **REJ601** is an overcurrent protection relay without circuit breaker control. Both products integrate protection, monitoring, and control functions into one unit. Leveraging ABB's profound expertise in protection and numerical technology, they offer excellent performance and usability in their category, suitable for feeder protection scenarios in primary and secondary distribution networks. ## II. Core Functions and Configurations ### 1. Protection Functions Both relays provide multi-level protection functions and support three application configurations (B, C, D). The core protection functions are as follows: | Protection Type | ANSI Code | Key Function Description | |--------------------------------|-------------------------|-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------| | Three-phase overcurrent protection | 51P (low-stage), 50P-1 (high-stage), 50P-2 (very high-stage) | Supports Definite Time (DT) and Inverse Definite Minimum Time (IDMT) characteristics, covering short-circuit and overcurrent protection; high-stage can operate instantaneously. The low-stage overcurrent protection supports IEC 61255-3, ANSI C37.112 standard curves, and special RI inverse time curves. | | Ground fault protection | 51N (low-stage), 50N (high-stage) | Based on external zero-sequence CT or internally calculated residual current; low-stage supports IDMT characteristics, high-stage can operate instantaneously. External measurement accuracy is ±5%, and internal measurement accuracy is ±15%. | | Transformer inrush detection | 68 | Identifies inrush current through second harmonic to prevent false tripping during transformer energizing; inrush threshold setting range is 0.2-25×In. | | Thermal overload protection | 49 | Provides thermal overload protection for feeders, cables, and transformers, calculating temperature rise based on a thermal simulation model, supporting heating/cooling time constant settings (1-300min). | | Phase discontinuity protection | 46PD | Monitors the ratio of negative sequence current to positive sequence current (I2/I1); the ratio setting range is 10%-100% to detect open-phase faults. | | Negative sequence overcurrent protection | 46 | Protects against asymmetric loads; start value is 0.1-1.5×In, operation delay is 0.1-300s, suitable for equipment such as motors. | | Circuit breaker failure protection | 50BF/50NBF | Detects circuit breaker faults; phase current operation value is 0.2-2.0×In, zero-sequence current is 0.1-2.0×In, supporting re-tripping and backup protection delay (0.06-0.5s). | | Auto-reclosing (REF601 only) | 79 | Supports up to 4 reclosure shots, with customizable reclosure intervals (0.2-300s) and pulse duration (0.2-20s), suitable for overhead line feeders. | ### 2. Configuration Differences The three application configurations cover different functional scopes to meet diverse scenario requirements: - **Configuration B**: Basic functions, including non-directional overcurrent and ground fault protection. - **Configuration C**: Builds on Configuration B by adding thermal overload protection, phase discontinuity protection, and circuit breaker failure protection. - **Configuration D** (REF601 only): Builds on Configuration C by adding negative sequence overcurrent protection and auto-reclosing functions, suitable for overhead line feeders. ## III. Application Scenarios Suitable for incoming and outgoing feeder protection in medium-voltage distribution networks, specifically including: - Short-circuit, overcurrent, and ground fault protection for overhead lines and cable feeders. - Main protection for distribution transformers (when paired with inrush detection function). - Feeder monitoring and control in industrial power systems, especially suitable for compact switchgear and retrofit projects. ## IV. Hardware and Interfaces ### 1. Input/Output Specifications | Type | Specification Details | |--------------|-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------| | Analog inputs | 4 CT inputs (3-phase current + 1 ground current), supporting 1A or 5A rated current; thermal withstand capability of 4×In for continuous operation, and 100A (1A CT)/500A (5A CT) for 1 second. | | Binary inputs | 4 configurable inputs, supporting 24-240V AC/DC, which can be mapped to signals such as blocking, reset, circuit breaker position, and trip circuit monitoring; input response time is 25ms. | | Binary outputs | 6 outputs (2 power outputs + 4 signal outputs), supporting tripping, alarming, status indication, etc. Power output contacts can carry 8A continuously and 30A for 0.5s; signal outputs can carry 6A continuously, with a minimum load of 100mA@24V AC/DC. | ### 2. Local HMI and Operation - **Local Human-Machine Interface**: Equipped with an alphanumeric LCD display, 6 LED indicators (normal/fault, start, trip, phase fault trip, ground fault trip, trip circuit fault), and navigation keys, supporting multi-language display. - **Access Control**: Three-level role-based authentication (operator, engineer, administrator) with support for key combination or alphanumeric password protection to prevent unauthorized access. ## V. Monitoring and Recording Functions 1. **Measurement Functions**: Real-time monitoring of three-phase current, ground current, negative sequence current, thermal level, and operation count; data can be accessed via local HMI or remote communication interface. 2. **Event Log**: Non-volatile memory stores 100 event records with 1ms timestamp resolution, including trip status, I/O status, relay fault codes, etc.; data is retained during power loss. 3. **Fault Recording**: Stores analog data (three-phase current, ground current) of the last 5 trip events with timestamps, supporting post-fault analysis. 4. **Self-Supervision and Testing**: Continuously monitors hardware and software status, issues alarms and blocks protection functions in case of faults to prevent misoperation; supports built-in test mode to verify HMI and output circuits. 5. **Trip Circuit Monitoring**: Real-time monitoring of trip circuit availability, detecting open-circuit faults in the circuit breaker's open/closed state and loss of control voltage. ## VI. Communication and Control - **Communication Function**: Optional Modbus RTU or IEC 60870-5-103 protocol, enabling remote monitoring via RS-485 bus (two-wire); communication cards can be added later. - **Control Function**: REF601 supports local/remote control of circuit breakers (closing/opening) via HMI buttons or communication commands, with 2 dedicated circuit breaker control outputs. ## VII. Technical Parameters | Category | Key Parameters | |------------------|-----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------| | Power supply | 24-240V AC/DC; voltage fluctuation range: AC 85-110%, DC 70-120%; power consumption <5VA; maximum DC ripple 12% (100Hz). | | Environmental conditions | Operating temperature: -25~+55℃; short-time service temperature: -25~+70℃ (<16h); humidity <93% (non-condensing); altitude ≤2000m; transportation and storage temperature: -40~+85℃. | | Electromagnetic compatibility | Complies with IEC 61000-4 series standards, with resistance to electrostatic discharge (contact 6kV/air 8kV), surges (common mode 4kV/differential mode 2kV), radio frequency interference (10V/m, 80-1000MHz), etc. | | Mechanical dimensions | Width: 130mm (frame)/121.5mm (case); height: 160mm (frame)/151.5mm (case); depth: 151.5mm; weight: 1.43kg; protection rating: IP54 (front), IP20 (terminal side). | ## VIII. Ordering and Accessories ### 1. Order Code Composition The order code consists of 11 digits, with key field meanings as follows: - 1st digit: Relay type (REF601/REJ601). - 2nd digit: Standard (ANSI/A or IEC/B). - 3rd-4th digits: Analog input type (1A/D4 or 5A/E4). - 7th digit: Communication protocol (Modbus RTU/B, IEC 60870-5-103/C, or none/N). - 8th digit: Application configuration (B/C/D). ### 2. Accessories - Communication card: CIM601BNNNNBANXG (for expanding communication functions). ## IX. Core Advantages 1. **Compact Design**: Adopts press-fit mounting without additional accessories, suitable for switchgear with limited space. 2. **Flexible Configuration**: Three application configurations cover different protection needs, supporting parameter customization and I/O remapping. 3. **High Reliability**: Comprehensive self-supervision and anti-interference design ensure stable operation in harsh environments. 4. **Usability**: Local HMI supports multi-language and intuitive operation; event and fault records facilitate operation and maintenance analysis. This product is suitable for feeder and transformer protection in medium and low-voltage distribution networks, as well as overcurrent and control scenarios in industrial power systems, serving as a cost-effective compact protection solution that balances performance and cost.