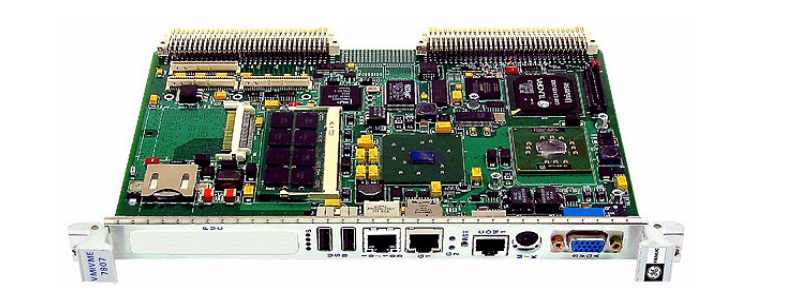

ABB NextMove ESB-2

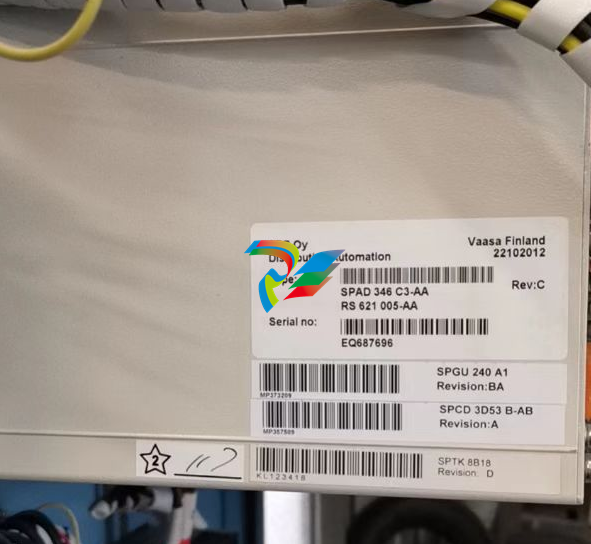

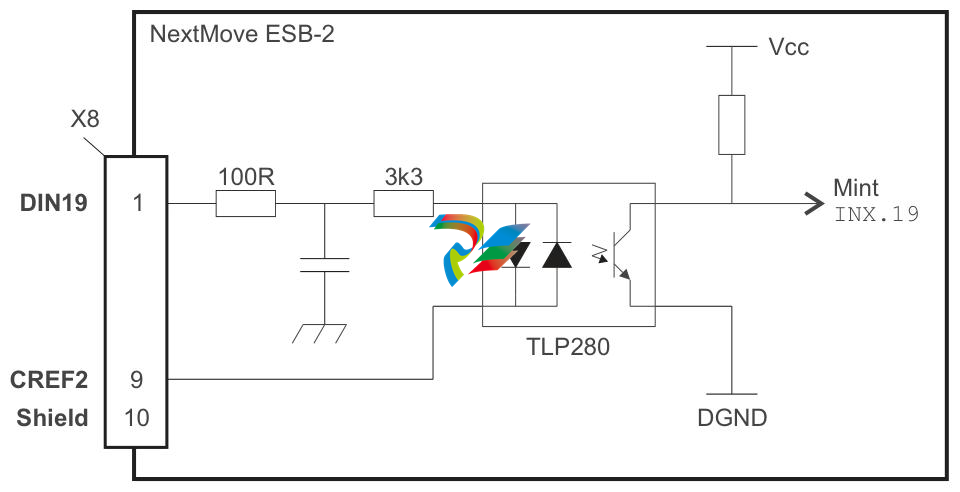

# Summary of ABB NextMove ESB-2 Motion Controller User Manual This manual comprehensively introduces the features, installation, configuration, operation, and maintenance of the ABB NextMove ESB-2 multi-axis intelligent motion controller. The following is a summary of key points: ## I. Overview and Safety Information ### 1. Controller Features The NextMove ESB-2 is a high-performance multi-axis controller supporting servo and stepper motor control. Its core features include: - Supporting **3-4 servo axes** and **4 stepper axes** (model-dependent), with additional encoder inputs for master-follower applications; - Integrating the Mint motion control language (a structured form of Basic, suitable for both simple and complex motion scenarios); - Rich I/O configuration: 20 digital inputs, 12 digital outputs, 2 channels of 12-bit differential analog inputs, and 4 channels of 12-bit analog outputs; - Communication interfaces: USB 1.1, CANopen/Baldor CAN protocols, and RS232/RS485 serial ports; - Supporting various motion types such as jogging, software cams, and gear synchronization, and can directly replace the NextMove ESB. ### 2. Safety Precautions - Only qualified personnel should operate the equipment to avoid high-voltage electric shock and electrostatic damage (ESD protection is required); - The equipment may be connected to rotating parts, and improper use may cause injury. The stop input cannot be used as the sole means of safe shutdown; - Electromagnetic fields may affect medical devices (such as pacemakers), and relevant personnel must stay away from motors and current-carrying conductors; - Compliance with local safety standards is required (such as the EU Machinery Directive, US NEC, etc.). ## II. Model and Receiving Inspection ### 1. Model Differences Different models vary in the number of servo axes, serial port types, and stepper output types. Key model parameters are as follows: | Model Example | Number of Servo Axes | Number of Stepper Axes | Additional Encoder Inputs | Serial Port Type | Stepper Output Type | |----------------|----------------------|------------------------|---------------------------|-------------------|----------------------| | NSB202-501 | 3 | 4 | 2 | RS232 | Differential (RS422) | | NSB203-502 | 3 | 4 | 2 | RS485 | Open Collector | | NSB204-501 | 4 | 4 | 1 | RS232 | Differential (RS422) | | NSB205-502 | 4 | 4 | 1 | RS485 | Open Collector | ### 2. Receiving Inspection - Check the integrity of the packaging and report transportation damage; - Verify that the model matches the order and record the serial number; - Long-term storage must meet environmental requirements (see 7.1.11 for humidity and temperature). ## III. Installation Requirements ### 1. Environmental and Mechanical Installation - Installation location: Indoor and fixed, avoiding heat sources, corrosive substances, and dust. Temperature range: 0-45°C; humidity: ≤80% (below 31°C) to 50% (at 45°C); - Mechanical fixing: Use M4 screws to mount on a vertical non-flammable surface, with heat dissipation slots reserved at the bottom. At least 20mm of heat dissipation space around, and additional 70mm space at connectors. ### 2. Power and Equipment Requirements - Power supply: +24V DC (2A continuous power supply), with a recommended independent 4A fuse for protection; - Supporting PC requirements: 1GHz processor, 512MB RAM, 2GB hard disk, USB/serial port, 1024×768 screen, supporting Windows XP and above. ## IV. Input/Output (I/O) Configuration ### 1. Analog I/O - **Analog inputs**: 2 differential inputs (±10V, 12-bit resolution, 120kΩ impedance, maximum 4kHz sampling rate), supporting single-ended/differential wiring; - **Analog outputs**: 4 bipolar outputs (±10V, 12-bit resolution, maximum 2.5mA output), used for servo drive demand signals, requiring shielded twisted-pair cables. ### 2. Digital I/O - **Digital inputs**: 20 opto-isolated inputs, divided into 3 groups (DIN0-3 are high-speed interrupt inputs with 1μs response; DIN4-11/12-19 are general inputs), configurable for level/edge triggering; - **Digital outputs**: 12 outputs (total current 500mA for DOUT0-7, 500mA for DOUT8-11), supporting drive enable and global error output. Inductive loads require freewheeling diodes. ### 3. Special I/O - **Stepper control outputs**: 4 outputs (0-500kHz). Differential models (NSB202/204) use RS422 drivers; open-collector models (NSB203/205) use ULN2803; - **Encoder inputs**: 5 incremental encoder inputs (A/B/Z differential signals, MAX3095 receiver), supporting 10MHz quadrature counting. Cable length affects maximum frequency (e.g., 1.3MHz for 2m, 7kHz for 1000m); - **Relay**: 1 relay output (1A@24V DC or 0.25A@30V AC). COM connects to NO under normal conditions and to NC in case of faults; - **Communication interfaces**: USB 1.1 (compatible with 2.0/3.0, maximum 5m cable), RS232/RS485 (up to 115.2Kbaud), CAN (RJ45 interface, supporting CANopen/Baldor CAN, requiring 12-24V power supply). ## V. Operation and Configuration ### 1. Software Installation and Connection - Install Mint WorkBench (requires administrator privileges) and connect the controller via USB or serial port; - Power-on check: The status display shows the node number (blinking by default). Faults are indicated by 0-7 with a decimal point, requiring reference to troubleshooting. ### 2. Axis Configuration - **Axis type selection**: Set axes as servo/stepper/virtual via the Axis Config Wizard and assign hardware channels; - **Scale factor (SCALEFACTOR)**: Convert encoder counts to user units (e.g., revolutions, millimeters). For example, a 1000-line encoder set to 4000 represents 1 revolution; - **Drive enable output**: Configure digital outputs or relays as drive enables and test enable state switching. ### 3. Testing and Tuning - **Stepper axis testing**: Use the `JOG(0)=2` command to test forward and reverse rotation and adjust speed parameters; - **Servo axis testing**: Use the `TORQUE(0)=5` command to test demand output and observe speed/position via the Spy window; - **Closed-loop control tuning**: - Proportional gain (KPROP): Improves response speed; excessive values cause oscillation; - Derivative gain (KDERIV)/velocity feedback (KVEL): Increases damping and reduces overshoot; - Integral gain (KINT): Eliminates steady-state errors, requiring an integral limit (KINTLIMIT); - Velocity feedforward (KVELFF): Reduces following errors, calculated as 2048/(quadrature counts per servo cycle). ### 4. Configuration Saving Generate a Startup Block via Mint WorkBench, save the configuration to a file, and load it for future use. ## VI. Troubleshooting ### 1. Status Display Meanings - Node numbers 1-15 are displayed in hexadecimal; numbers >15 are displayed as three horizontal lines; - Fault codes: 0-7 with a decimal point indicate startup faults, requiring contact with technical support; - Axis status symbols: e.g., "J" for jog, "E" for error, "S" for stop. ### 2. Common Issues - **Communication problems**: Check power supply, cable wiring, USB driver installation, and power cycle after firmware update; - **Motor not rotating**: Check drive enable configuration, wiring, and servo gains; - **Motor runaway**: Verify common grounding, encoder feedback polarity, and whether the drive input is 0V at zero demand; - **CAN issues**: Ensure termination resistors (120Ω) are only connected at both ends, consistent baud rates, and unique node IDs. ## VII. Technical Parameters and Accessories ### 1. Core Parameters - Power supply: 24V DC±20%, power consumption 50W; - Environment: Operating temperature 0-45°C, humidity ≤80% (non-condensing), altitude ≤2000m; - Dimensions: 245×140×45mm, weight ~700g. ### 2. Accessories - Feedback cables (CBL015MF-E3B, etc., maximum 30.5m); - Baldor CAN nodes (input/output/relay nodes); - HMI panels (character/touchscreen, supporting serial/CANopen); - Mint NC software (converts CAD to motion control code).