ABB strip tension load cells in processing lines

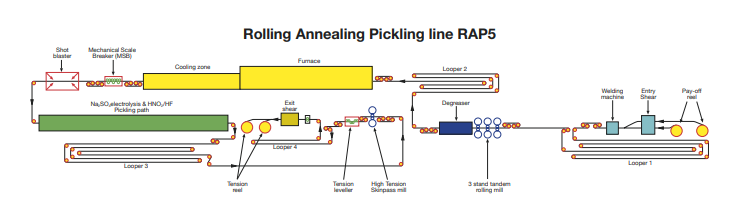

Pressductor® Technology load cells – a superior alternative to strain gauge tension load cells The production of cold rolled stainless steel coils from hot strip today typically consists of a series of separate processes: annealing, pickling, cold rolling and skin pass rolling. Outokumpu’s line in Tornio Finland, supplied by Danieli, is the latest alternative to the market evolution by introducing new technologies for stainless steel within one integrated processing line. The RAP 5 line (Rolling-Annealing-Pickling) incorporates all the processes in a continuous line: tandem cold rolling mill, annealing furnace, pickling section, skin pass mill. This world-first integrated line can process both hot and cold rolled stainless steel strips. The cold rolling plants in Tornio produce stainless steel sheet and coil, most of which is sold to customers in Europe and Asia. Tension control is one of the most important process parameters in strip processing lines. In order to achieve good tension control you need reliable input of the actual tension. Therefore the selection of reliable tension load cells is crucial. For Outokumpu the choice stood between Pressductor technology and strain gauge technology. In a thorough evaluation Outokumpu pointed out the extensive experience of using Pressductor load cells in other applications. In addition, the good long-term relations with ABB including reliable technical and local support made Outokumpu choose the Pressductor alternative. ”Tension control is one of the most important process parameters in a strip processing line. Therefore the selection of reliable tension load cells is crucial.” The continuous RAP 5 line consists of a three-stand tandem mill, annealing and pickling units, a skin pass mill and a tension leveling unit. The line is 800 m long and occupies all of the three floors of the No. 2 cold rolling plant. The horizontal loopers allow the RAP line to be used continuously and when fully loaded, there is up to 4000 m of strip in the line

In the RAP 5 line, one of the world’s largest process lines, there are totally 28 ABB strip tension systems (56 Pressductor PillowBlock load cells) installed, from the rolling section to the tension leveling and skin pass mill sections. ABB and its Pressductor load cells fully take care of the strip tension measurement in the line. ABB’s high performance load cells are based on the unique Pressductor technology principle, patented in 1954. The ABB PillowBlock type of load cells has proven their outstanding dependability in demanding strip tension measurement applications in both rolling mills and processing lines. The furnace sections, always with high temperatures, are another important and demanding application where ABB PillowBlock load cells have been evaluated as the best solution.

In a comparison between Pressductor load cells and strain gauge tension load cells, there are several benefits with the Pressductor Technology. ABB’s Pressductor load cells stand for accurate and reliable measurement with: • No need for constant re-calibrations • No need to re-zeroing due to zero drift • Wide measurement range • Extremely long service life.

Load cell types Capacity PFTL 201C 20 kN, 50 kN PFCL 201C 20 kN, 50 kN PFTL 201D 100 kN