ABBconverter for standard signals

— Flow in air pressure

— Proven and reliable concept

— Integral mount design

• Small dimensions, low weight

— Sturdy construction and solid functionality • Influence of shock and vibration < 1 % bei 10 g — Variety of signal ranges

• Input e.g. 0 to 20 mA or 4 to 20 mA

• Output 0.2 to 1 bar (3 to 15 psi) — Wide temperature range

• From –40°(optional –55°) to 85° C (–40° [optional 67°] to 185°F) — Approvals for explosion protection

• ATEX, FM / CSA, EACEx for intrinsically safe and pressure-resistant operation

Concept The TEIP11 signal converter converts standard electrical signals, e.g. 4 to 20 mA to 0.2 to 1 bar (3 to 15 psi). It is therefore a connecting link between electrical/electronic and pneumatic systems. The signal conversion process is similar to the patented force balance method. Special features of the TEIP11 signal converter are its relatively small dimensions and outstanding operational stability when subject to shock and vibration. The converter can be subjected to loads up to 10 g with less than 1% effect on function. The housing units are available in a variety of models to meet your installation requirements. For potentially explosive conditions, units that offer intrinsically safe operation or pressure-resistant encapsulation are available with international approval certificates for use worldwide. Various ranges can be supplied on the input side and the output side for signal conversion (see Specification on page 4). The device requires only compressed air 1.4 to 10 bar (20 to 145 psi) for the power supply. In order to ensure smaller dimensions and lower costs, an air power stage is not included in the pneumatic unit. This reduces the air capacity, meaning that the I/P signal converter can only be used to control small-volume air systems.

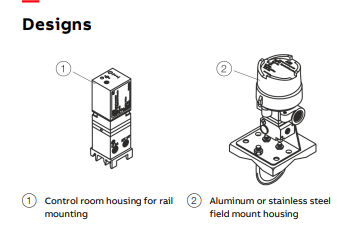

Control room housing unit for rail mounting The control room housing for rail mounting is the simplest and lowest priced version of the I/P signal converter. A mounting base that is compatible with all commercially available EN rails is used for installation. The housing unit with plastic cap has an IP 20 protection rating. Field mount housing The field mount housing is suited for installation on-site or in open areas. The housing can be made from plastic with IP rating IP 54, from aluminum with IP rating IP 65 and from stainless steel with IP rating IP 65. The housingSpecification Input (electric) Signal range 0 to 20 mA or 4 to 20 mA 0 to 10 mA or 10 to 20 mA 4 to 12 mA or 12 to 20 mA (additional ranges available upon request) Input resistance Ri = 260 Ω at 20 °C (68 °F), Tk + 0.4 %/K Overpressure limit 30 mA (for Ex devices see ). Capacitance / inductance Negligible Output (pneumatic) Signal range 0.2 to 1 bar (3 to 15 psi) Air capacity at supply air pressure [kg/h] [Nm3/h] [scfm] 1.4 bar (20 psi) 0.05 0.041 0.024 2.0 bar (30 psi) 0.07 0.057 0.033 4.0 bar (60 psi) 0.10 0.082 0.048 6.0 bar (90 psi) 0.16 0.130 0.076 10.0 bar(150 psi) 0.25 0.205 0.120 Power supply (pneumatic) Instrument air Free of oil, water, and dust acc. to DIN/ISO 8573-1 Pollution and oil content according to Class 3 Pressure dew point 10 K below operating temperature Supply pressure 1.4 to 10 bar (20 to 145 psi) Output signal 0.2 to 1 bar (3 to 15 psi) Air consumption Equivalent to air capacity Transmission data and contributing factors Characteristic curve Linear, direct, or reverse action Characteristic curve deviation ≤ 1 % Hysteresis ≤ 0.3 % Dead band ≤ 0.1 % Temperature ≤ 1 % / 10 K within –20 to 85 °C (–4 to 185 °F) ≤ 2 % / 10 K within –55 to –20 °C (–67 to –4 °F) Power supply ≤ 0.8 % at 1.4 to 2 bar (20 to 30 psi) ≤ 0.8 % at 2 to 3 bar (30 to 45 psi) ≤ 0.5 % to 3 to 10 bar (45 to 150 psi, each 1 bar [15 psi]) Mechanical vibration ≤ 1 % to 10 g and 20 to 80 Hz Seismic vibration Meets the requirements of DIN IEC 68-3-3 Class III for strong and strongest earthquakes. Mounting orientation Zero point≤ 0.5 % at 90° change of position Step response 10 to 90 % and 90 to 10 % 0.6 s 5 to 15 % and 15 to 5 % 0.25 s 45 to 55 % and 55 to 45 % 0.2 s 85 to 95 % and 95 to 85 % 0.15 s EMC Meets the requirements of EMC Directive 2014/30/EU (increased interference immunity as per EN 50082-2 PR) CE Marking Complies with the EC directive for CE conformity

Operating conditions at installation site Ambient temperature Depending on the ordered model: −40 to 85 °C (−40 to 185 °F) –55 to 85 °C (–67 to 185 °F) For Ex d: −40 to 85 °C (−40 to 185 °F) Mounting position Any Environmental capabilities Climate class GPF or FPF acc. to DIN 40040 Temperature: –55 to 85 °C (–67 to 185 °F), –45 to 85 °C (–49 to 185 °F) Relative humidity for operation, storage, or transport: 75 % average, 95 % short-term, no condensation Expected service life of the device With proper use and consideration of relevant environmental conditions, the service life of the TEIP11 can reach approx. 10 years. Regular maintenance work and / or proper repairs by ABB Service, along with the use of ABB spare parts, can extend the service life of the TEIP11

Design for rail mounting Material / IP rating IP 20 aluminum housing unit, with plastic cover Mounting Rail mounting: EN 50022 - 35 × 7.5 EN 50035 - G 32 EN 50045 - 15 × 5 Electrical connection 2-pole screw terminal for 2.5 mm2 (14 AWG) Pneumatic connection ⅛ NPT threaded hole for supply air and output Weight 0.25 kg (0.55 lb) Dimensions Refer to Design for control room housing unit for rail mounting on page 10.